Combined heat exchanger

A heat exchanger and combined technology, which is applied in the field of heat exchangers of electrical appliances, can solve the problems of frosting and icing on the surface of the evaporator, difficulty in drainage of condensed water, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

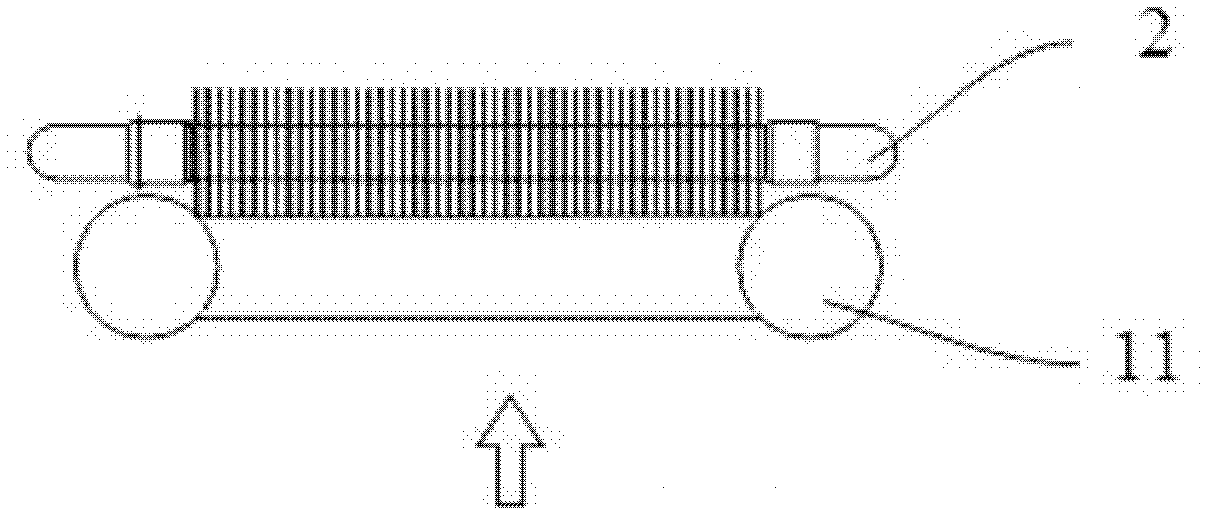

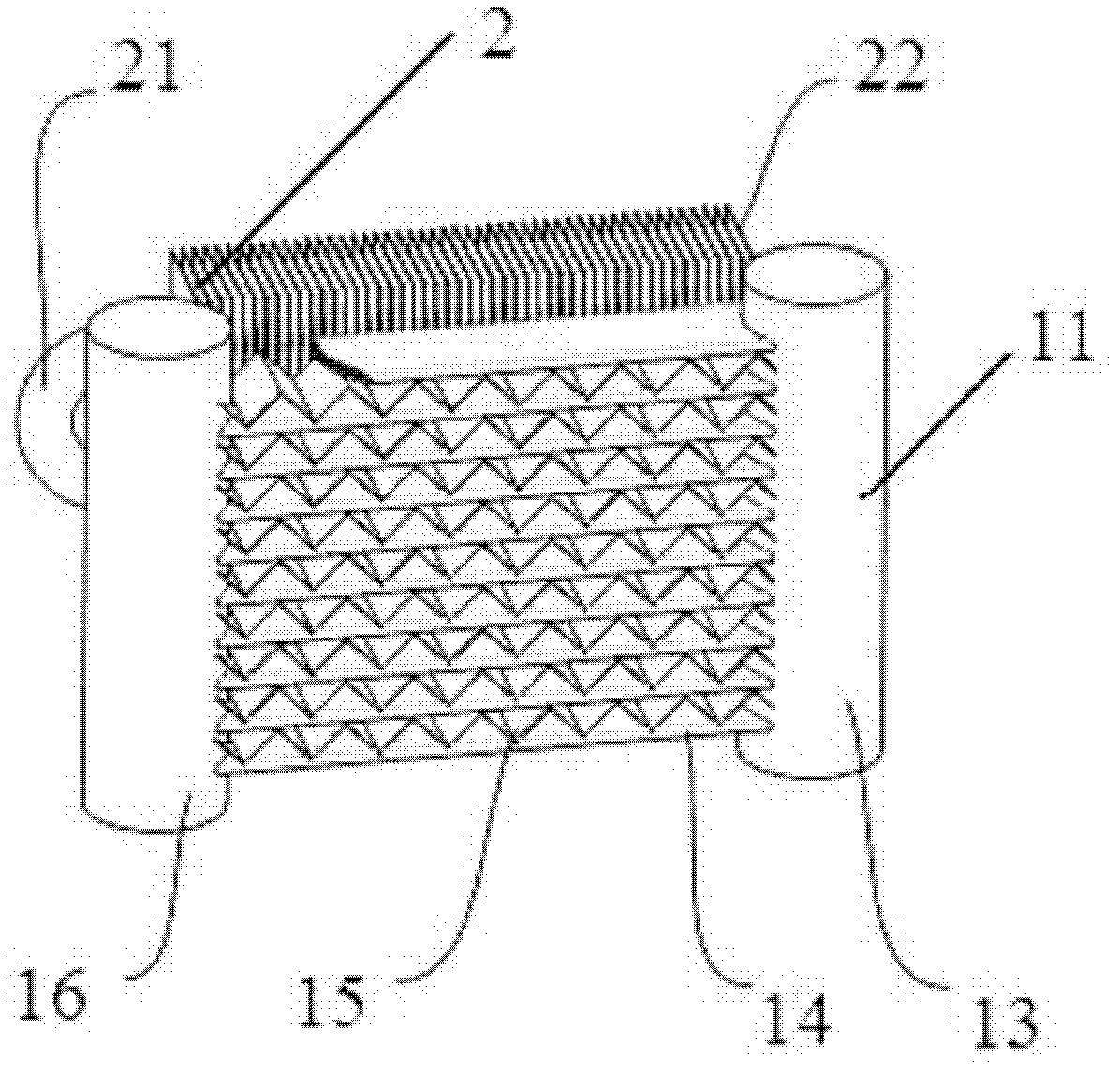

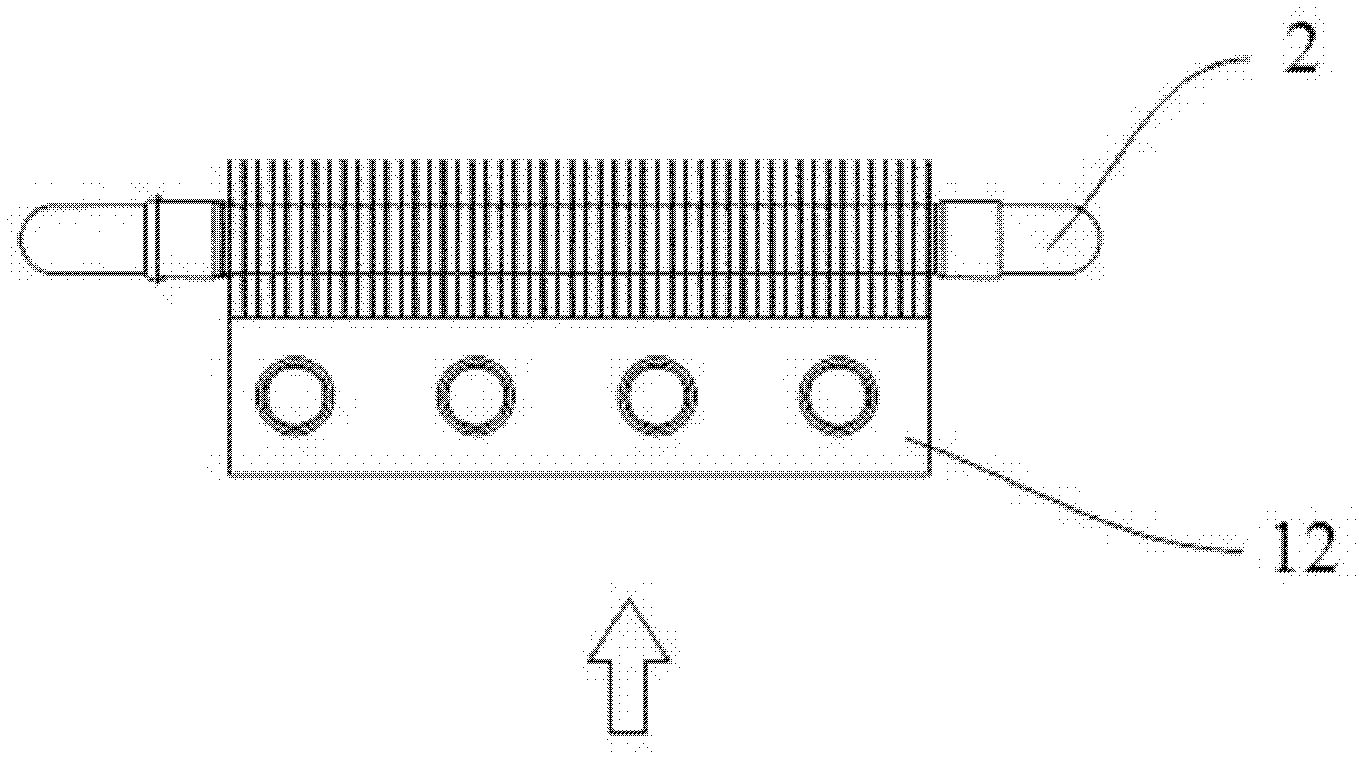

[0025] The combined heat exchanger of the present invention combines two heat exchangers together, specifically, a microchannel heat exchanger or a heat pipe heat exchanger or a similar type of heat exchanger that is difficult to automatically drain is placed in the combined heat exchanger Windward side: Place the heat exchanger with longitudinal fins on the leeward side of the combined heat exchanger. Preferably, the heat exchanger can use a highly hydrophilic material as the longitudinal fins, and the longitudinal fins are in close contact with On the windward side of the microchannel heat exchanger or heat pipe heat exchanger surface, these longitudinal fins form channels that guide the discharge of condensate accumulated on the surface of the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com