Moisture two-phase flow measuring device with annular chamber gas-liquid separation pressure measuring device

A flow measurement device and gas-liquid isolation technology, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring differential pressure, which can solve the problems of low efficiency of gas-liquid isolation, long dynamic balance process, and low signal-to-noise ratio To achieve the effect of speeding up the gas-liquid dynamic equilibrium process, high gas-liquid isolation efficiency, and improving safety and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below with reference to the accompanying drawings.

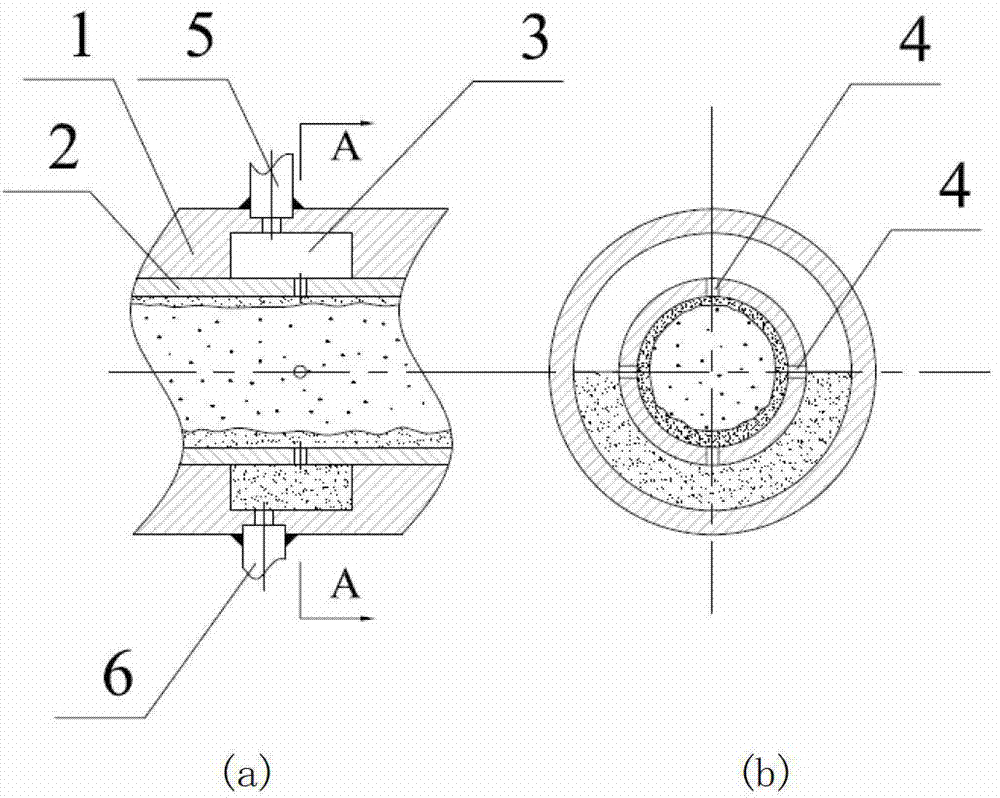

[0014] The present invention is an annular chamber gas-liquid isolation pressure taker used in the wet gas flow measuring device, the structural diagram is as follows figure 1 shown. The moisture measuring device may be a cone throttling device, a Venturi throttling device, a nozzle and orifice throttling device throttling device, etc. for moisture measurement.

[0015] In the present invention, a middle ring chamber gas-liquid isolation pressure taker 1 is arranged at each pressure take place on the measuring pipeline 2 of the wet gas two-phase flow measuring device. Four pressure-taking holes 4 are set on the same plane where the pressure-taking place of the measuring pipeline 2 is perpendicular to the axis, two at the maximum diameter in the horizontal direction, two at the maximum diameter in the vertical direction, and four pressure-taking holes 4 An ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com