Onboard LED automatic testing method

An automatic testing, onboard technology, applied in the direction of lamp testing, testing optical performance, etc., can solve the problems of reducing the efficiency of inspection, increasing the cost of LED inspection, and improving the complexity and difficulty of inspection work, so as to improve the efficiency and shorten the shutter time. , The effect of simplifying the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

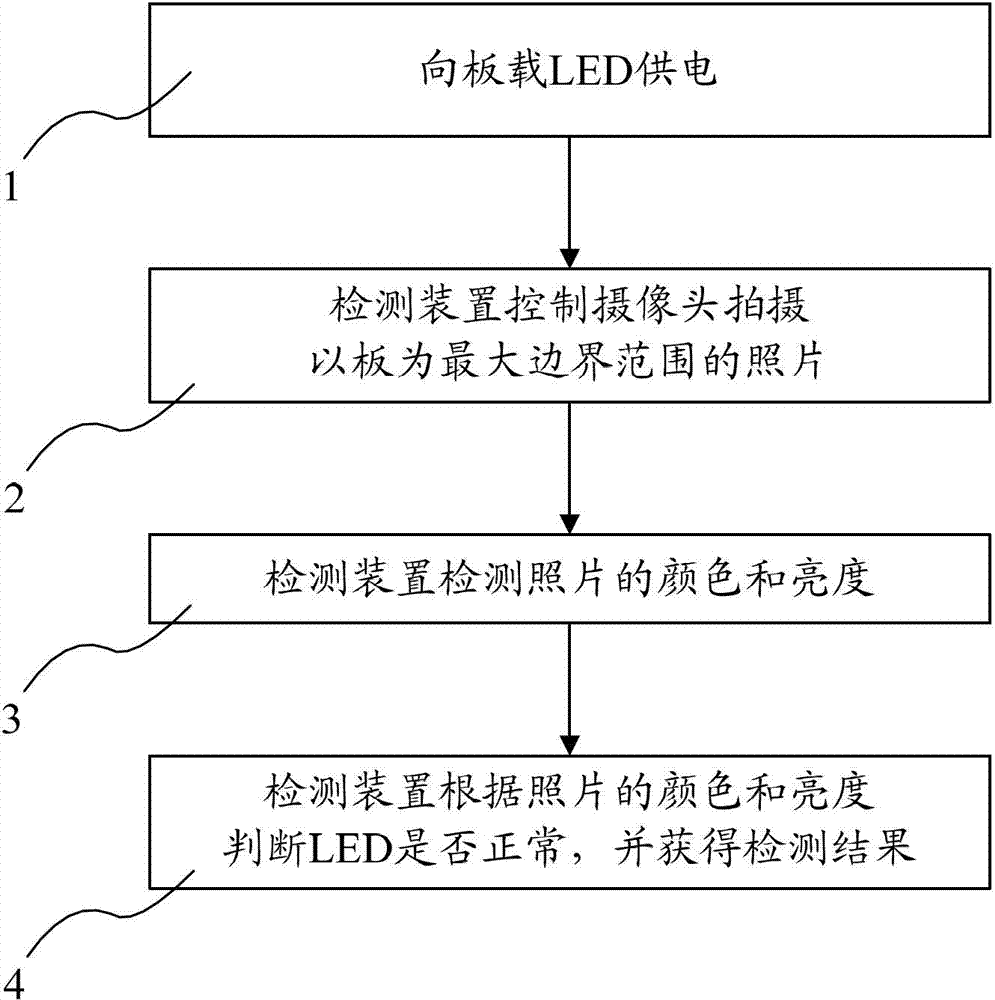

[0025] In one embodiment, the method comprises the steps of:

[0026] (1) supplying power to the on-board LED, and the on-board LED is arranged on a circuit board or panel;

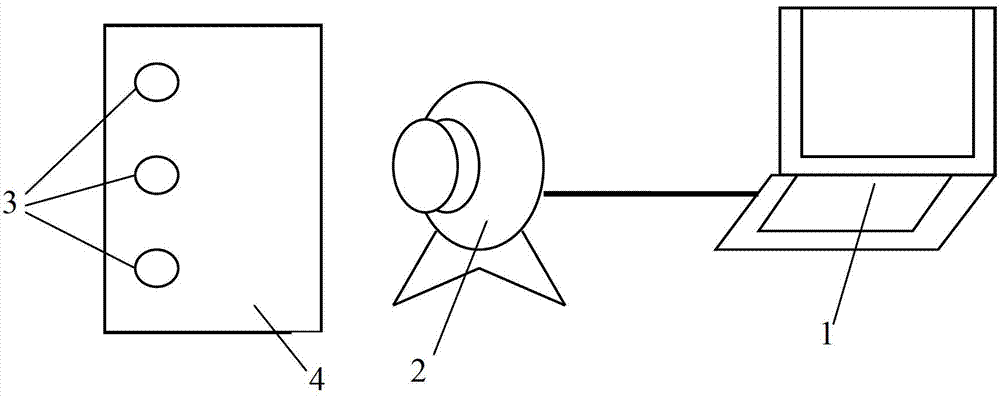

[0027] (2) The detection device controls the camera to take photos with the board as the maximum boundary range;

[0028] (3) The detection device detects the color and brightness of the photo;

[0029] (4) The detection device judges whether the LED is normal according to the color and brightness of the photo, and obtains the detection result.

[0030] In a preferred embodiment, the power supply to the onboard LED described in step (1) is specifically to supply power to the onboard LED, so that when the background brightness is 20-30, the LED to be detected reaches 90-100 Brightness range (LED brightness RGB three colors are 0~255, corresponding brightness range is 0~100). And the shortest exposure time for the camera to take photos with the board as the maximum boundary range is 1 / 1500 second, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com