Control method and control system of compact shelving system

A technology of a compact shelf system and a control method, which is applied in the field of control of the compact shelf system and its control system, can solve problems such as wrong judgments, imperfect methods and structures, safety accidents, etc., and achieve accurate and reliable identification and judgment, and simple control methods Reasonable and avoid the effect of misoperation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

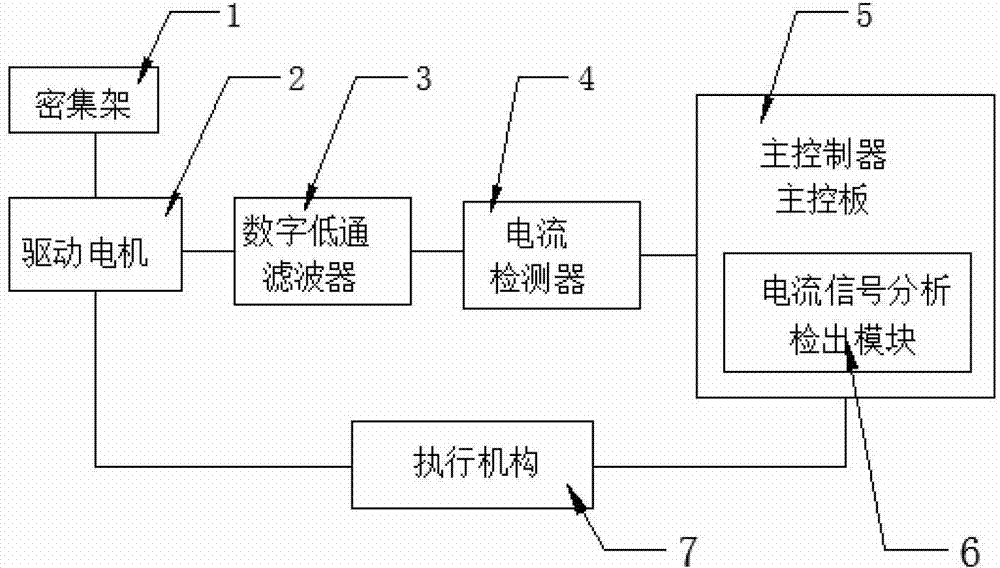

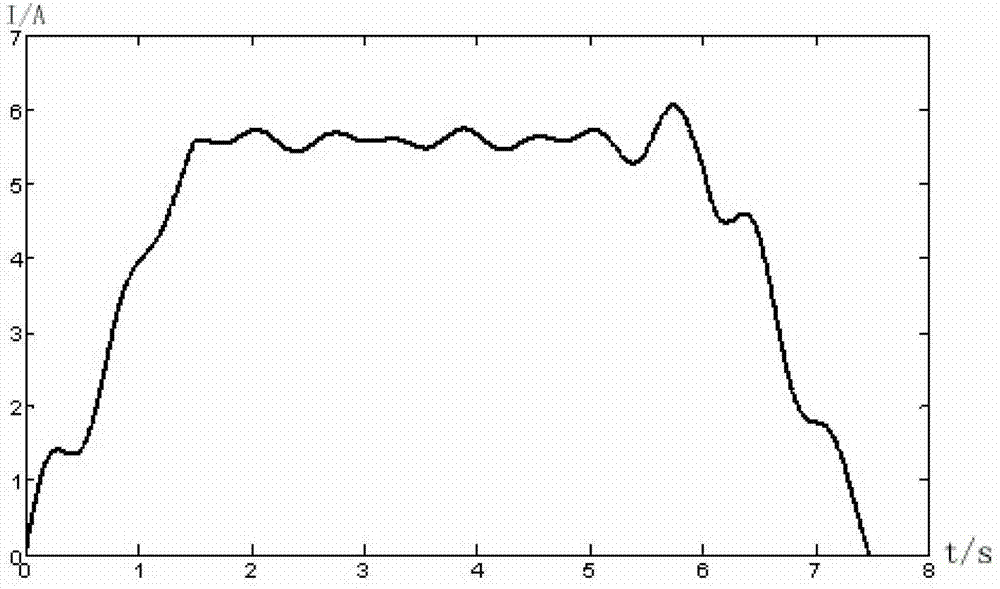

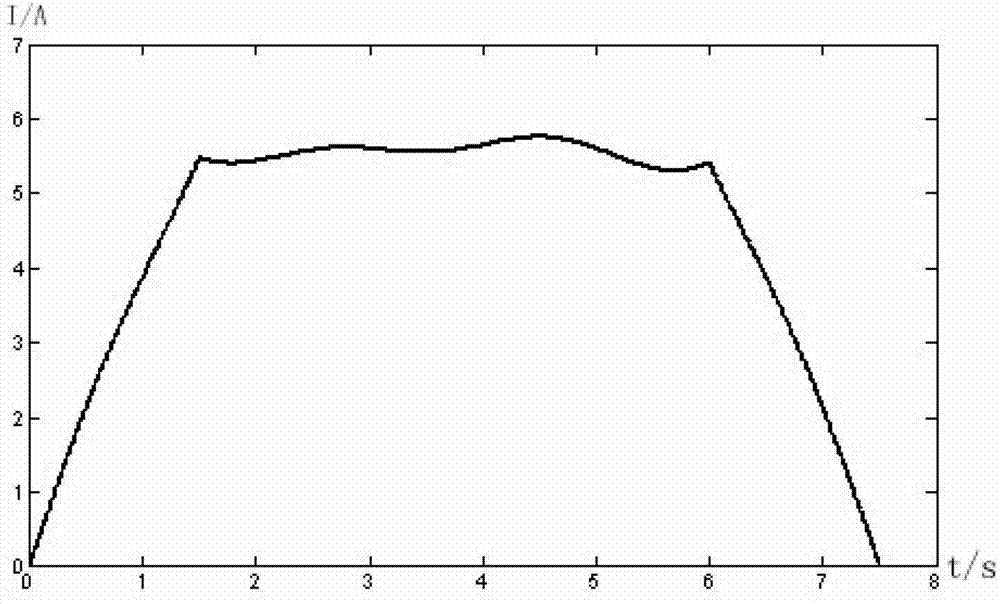

[0022] The present invention will be further described by way of embodiment now in conjunction with accompanying drawing. Usually, the compact rack operates in a smooth start, high-speed operation, and soft closing mode. The control method of the control system of the present invention includes safety protection control. When it increases, the current will increase relatively, but the change law will not change this characteristic. When the compact rack is in any of the above-mentioned operating stages, if it is subjected to unexpected external force or interference, the current law of the drive motor relative to the normal operation of the corresponding stage and \ Or the amplitude (size) changes, that is, it is judged that there are people in the rack or the compact rack is in an abnormal state, and the current detector is used to detect the current signal of the amplitude or regular change, and then the current signal analysis and detection module passes it based on the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com