Design structure of battery box for electromobile

An electric vehicle and design structure technology, applied in structural parts, electric power devices, battery pack parts, etc., can solve the problems of low insulation safety level, low fixing strength, unfavorable lightweight design of battery boxes, etc., to reduce design and production cost, the overall structure is simple and reliable, and the effect of good ventilation and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

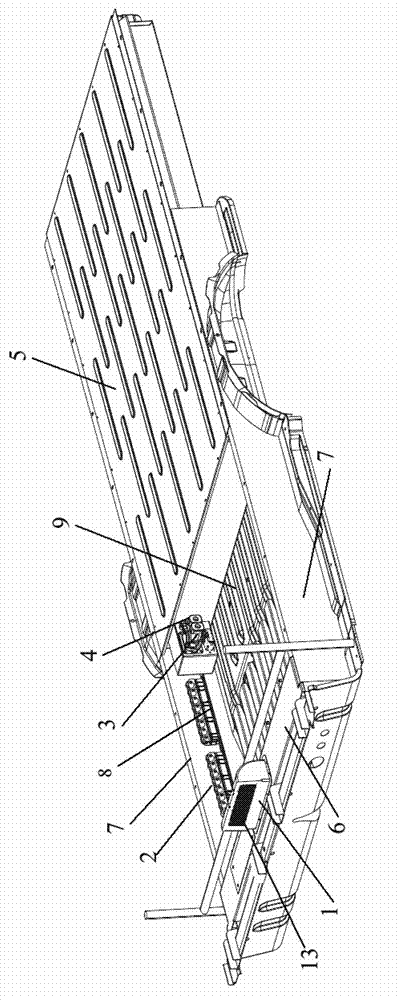

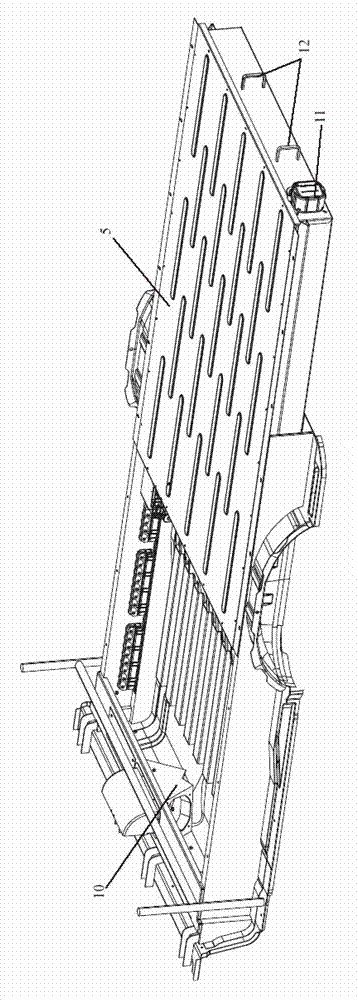

[0026] like Figure 1-2 The design structure of a battery box for an electric vehicle shown in the present invention includes an integrated battery box and a fixing frame fixedly connected to the compartment floor 9 for fixing the battery box therein.

[0027] Among them, the integrated battery box integrates the power battery, battery management system, and high-voltage electronic accessories, which effectively reduces the weight of the multi-box battery box design, reduces the number of external wires from the battery box, and makes the wiring harness arrangement orderly. The power line, collection line and battery module of the power battery are arranged in the battery box; the line connection between the battery modules in the battery box is connected with soft copper sheets, which not only facilitates the installation of the battery module, but also redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com