Non-contact power supply system and method for mobile device moving along track

A mobile device and orbital operation technology, applied in electromagnetic wave systems, circuit devices, electrical components, etc., can solve the problems of rigid power supply mode, unfavorable speed increase of mobile devices, high cost, etc. The effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

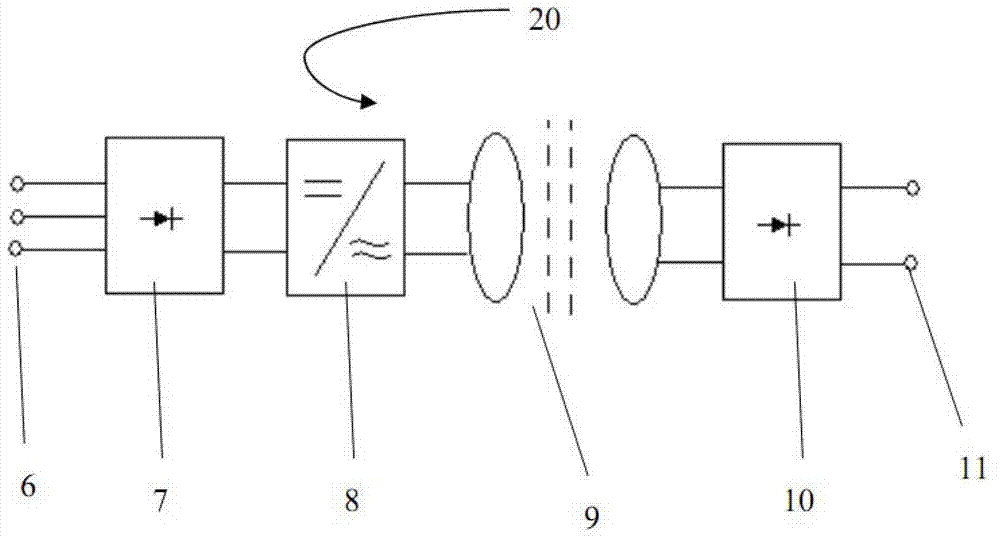

[0030] figure 2 is a contactless power supply system 20 for a mobile device running along a track according to the present invention. Wherein the alternating current 6 provided by the ground power supply first passes through the first rectifier 7 . The first rectifier 7 rectifies and filters the alternating current 6 provided by the ground power supply, and converts it into direct current.

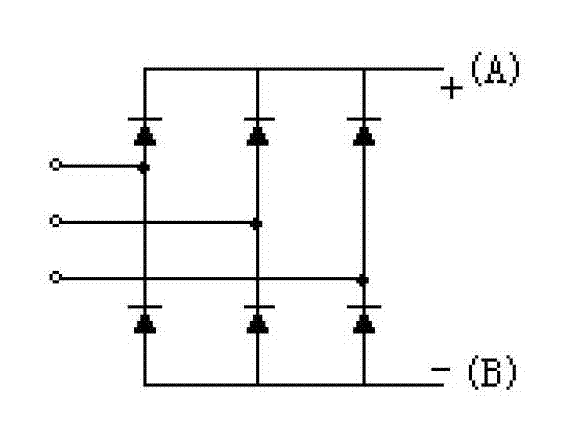

[0031] In one embodiment, the alternating current 6 provided by the ground power supply is three-phase alternating current. The first rectifier 7 is for example image 3 The conventional three-phase diode uncontrolled rectification circuit shown converts three-phase alternating current 6 into direct current. Since those skilled in the art refer to the attached image 3 It is easy to understand the working principle of the first rectifier 7 in this embodiment, and the circuit will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com