Improved straw outlet device of machine capable of crushing straw, applying fertilizer, performing sowing and covering straw

A straw covering machine and straw crushing technology, which is applied in the direction of harvesters, crop processors, agricultural machinery and machinery, etc., can solve the problem of uneven crushing of straw, and achieve the effect of eliminating uneven spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

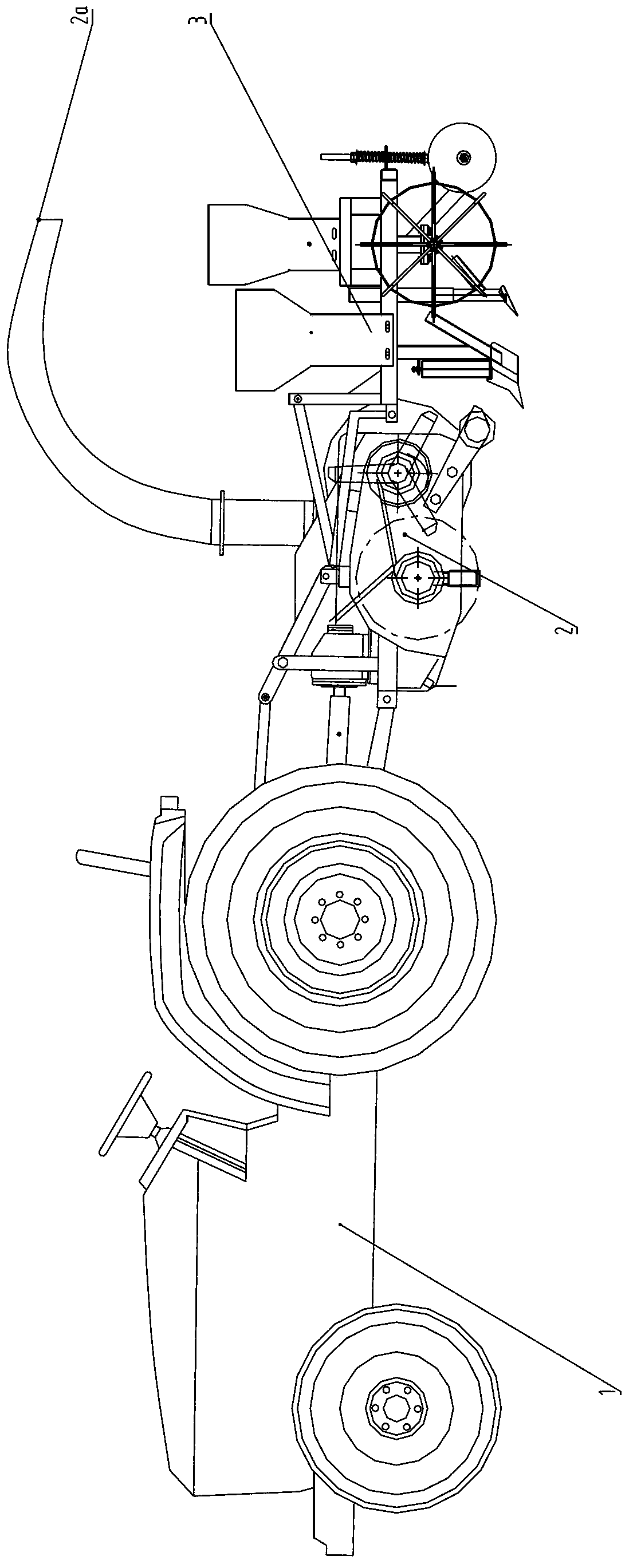

[0039] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

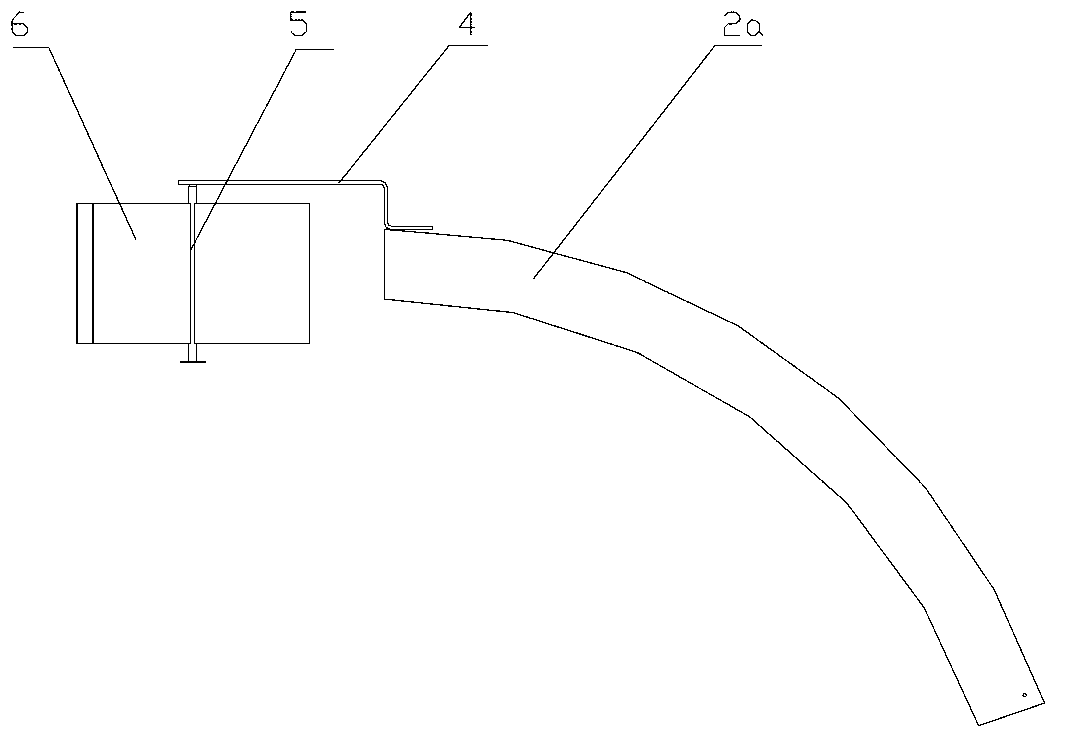

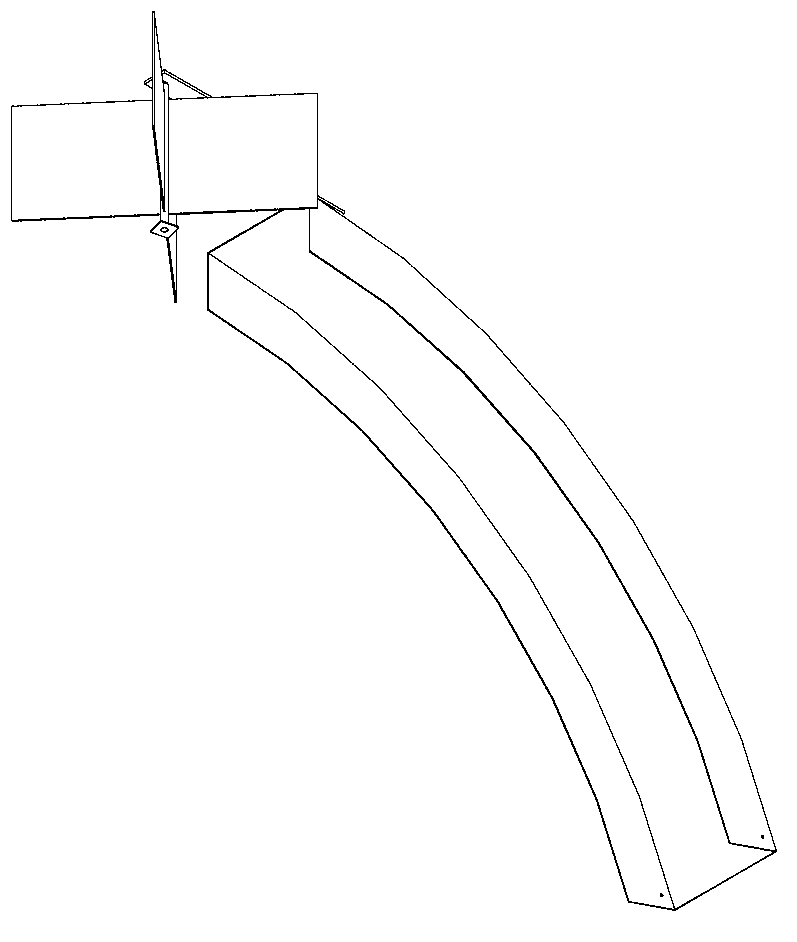

[0040] A device for improving the spit out of a broken straw fertilization and seeding machine, including a pipeline 7 that spans backward across the top of the integrated fertilization and seeding machine, and the outlet of the pipeline 7 is biased to the left or right side and protrudes backward A cantilever 8, a rotating shaft 9 is vertically arranged at the end of the cantilever 8, and a plurality of blades 10 that can rotate around the rotating shaft 9 are arranged on the rotating shaft 9;

[0041] The vertical height of the blade 10 is 1-1.8 times the height of the outlet opening of the pipeline 7;

[0042] The horizontal width of the blade 10 is 1-1.5 times the width of the outlet opening of the pipeline 7;

[0043] The distance between the rotating shaft 9 and the outlet of the pipeline 7 is 1-1.5 times the width of the blade 10 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com