Metal cold-drawing device with automatic unhooking function

A drawing device and automatic decoupling technology, applied in the field of drawing machine equipment, can solve the problems of complex equipment structure, unfavorable promotion and popularization, high equipment investment, etc., and achieve the effects of increasing enterprise benefits, wide application range, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

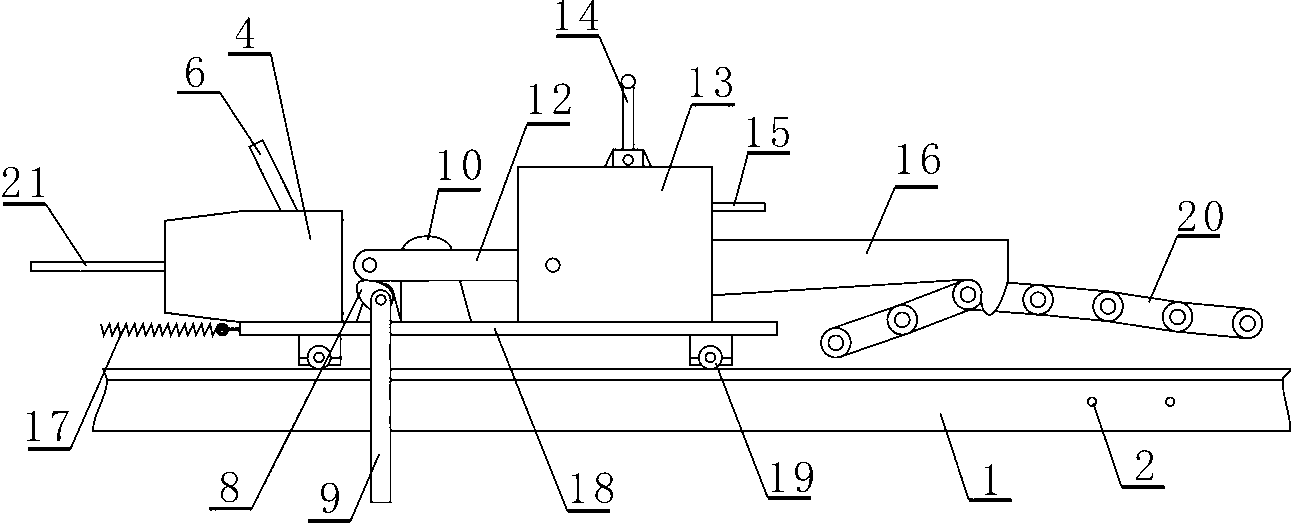

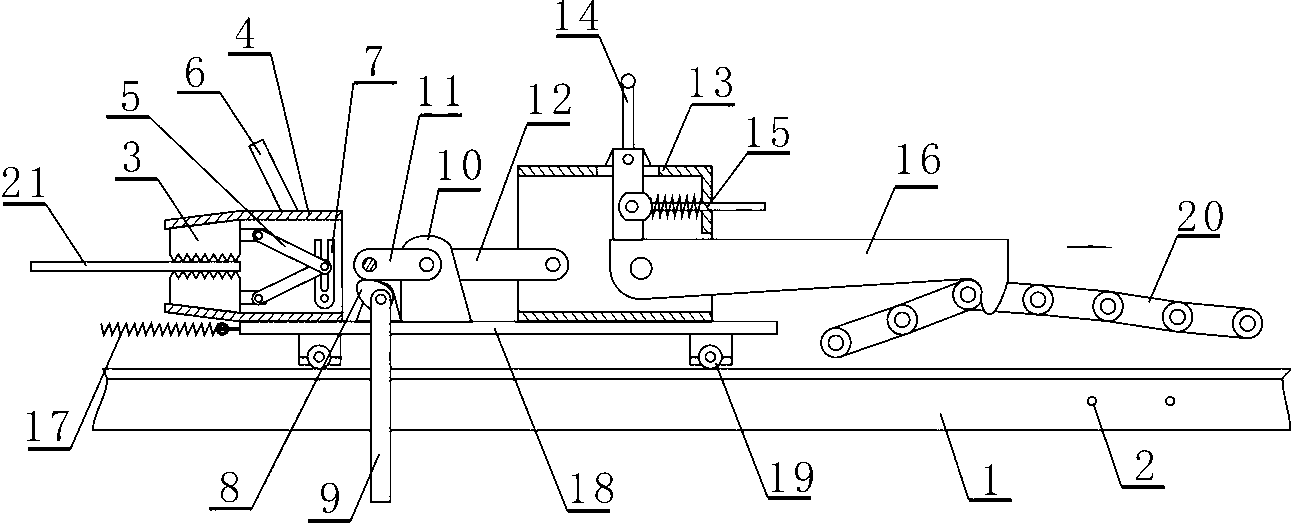

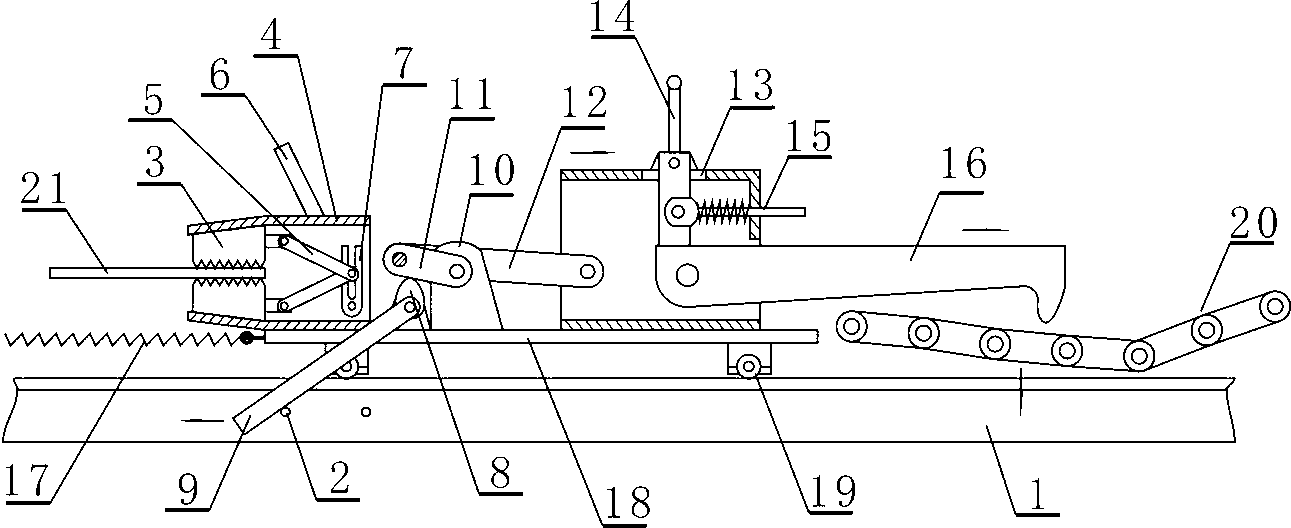

[0014] like Figure 1~Figure 3 As shown, the short arm of the crank sliding mechanism is a short connecting plate 11, and the long arm is a long connecting plate 12; one end of the short connecting plate 11 is axially connected to the connecting plate support 10, and the other end is axially connected to one end of the long connecting plate 12. The other end of the plate 12 is pivotally connected to the hook device. Alternatively, there are two long connecting plates 12, and the two long connecting plates 12 are connected to one end of the short connecting plate 11 through a common shaft. The curved arm mechanism formed by the long and short connecting plates is the key to realize automatic decoupling. A long connecting plate 12 and a short connecting plate 11 are axially connected to achieve the purpose of the present invention, but it is not as good as two long connecting plates 12 and a short connecting plate. The structure of the plate 11 is stable.

[0015] like Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com