Transmission mechanism for welding head of welding device

A technology of transmission mechanism and welding device, which is applied to auxiliary devices, transmission devices, welding equipment, etc., can solve the problems of low transmission efficiency and damaged parts to be welded, and achieve the effect of reasonable movement, slow and gentle contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

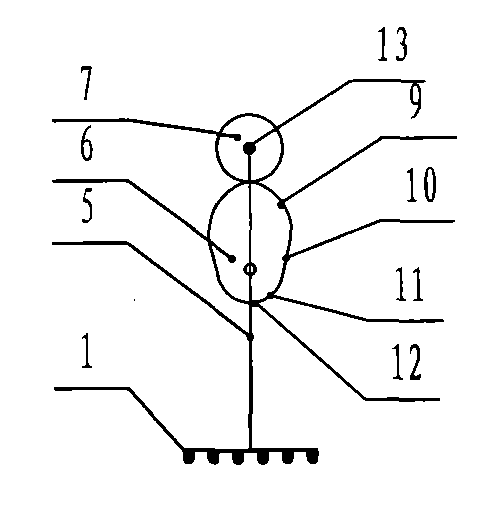

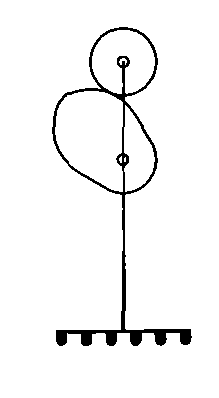

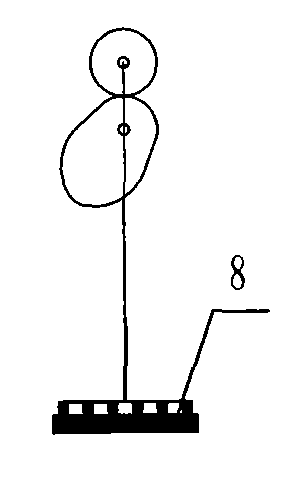

[0025] like Figure 1-7 Shown, the transmission mechanism of the welding head of the present invention is a cam mechanism, preferably the centering roller moves the follower disc cam mechanism, and it includes a cam 6 and a roller 7 as a roller, connected to one end of the rod 5 by the roller It is connected with the roller shaft 13, preferably hinged, and the other end is fixedly connected with the welding head 1. The rotating shaft of cam 6 is connected with power unit. The profile of the cam 6 includes a section 9 with a large radius of curvature and a section 11 with a small radius of curvature. During work, the cam 6 rotates in the counterclockwise direction. At the beginning, due to the large radius of curvature section 9, the radius of curvature at its top is the largest, and the radius of curvature of the profile of the cam 6 changes greatly, so the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com