Sensor installation structure in circular seam back-chipping edge milling machine

A technology of installation structure and edge milling machine, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of complex fixture structure, high processing cost, cumbersome adjustment, etc., to ensure processing quality and stability , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

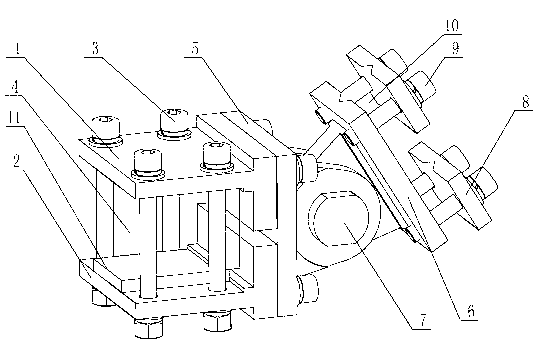

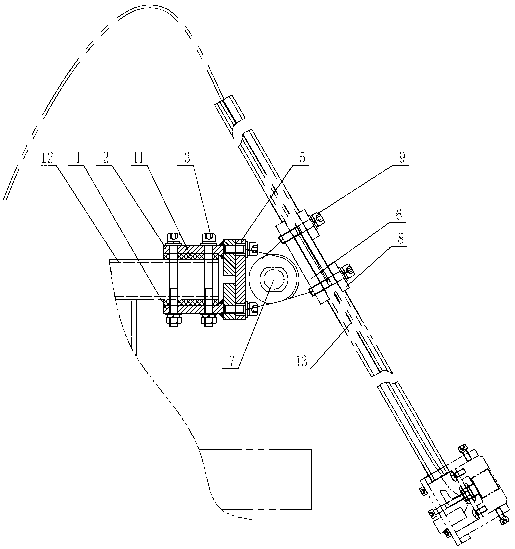

[0017] See figure 1 , the present invention includes an upper chuck 1 and a lower chuck 2, the upper chuck 1 and the lower chuck 2 have the same structure, which is a "T" structure, the upper chuck 1 and the lower chuck 2 are connected by a fastener 3, And form an installation space 4, the fastener 3 adopts bolts, nuts and gaskets, the upper chuck 1 and the lower chuck 2 can also be made into an integrated structure, the advantage of the split structure is that it can save materials and reduce production costs; The side walls of the upper chuck 1 and the lower chuck 2 are fixedly connected with the hanging feet 5, and the hanging ring 6 is connected with the hanging feet 5 through the pin shaft 7; The space two 10, the fastener two 9 adopt screws; the mounting surface relative to the pressing plate 8 and the suspension ring 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com