Temperature-rising method of sulfur combusting furnace

A sulfur burning furnace and sulfur technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of diesel waste, production, delay in production, etc., and achieve the effect of saving diesel and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

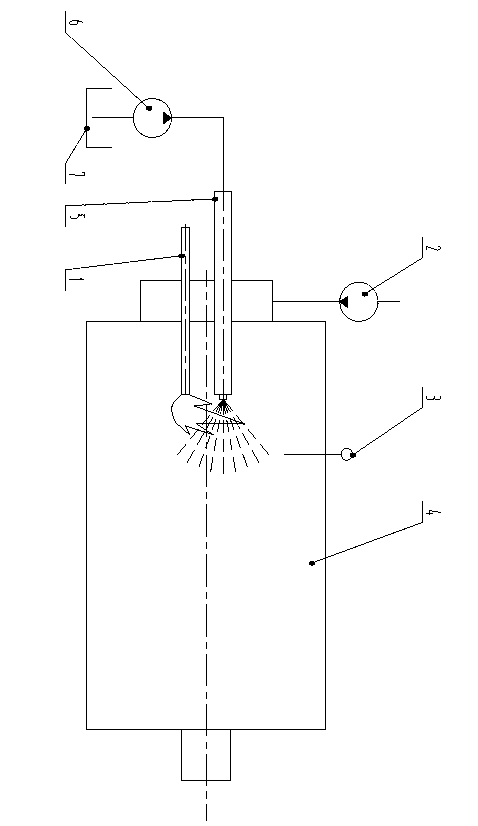

[0017] Example: Step 1, start fan 2, and send air into sulfur-burning furnace 4; Step 2, open the valve of the fuel tank connected to ignition gun 1, light ignition gun 1 with electronic ignition controller, and ignition gun 1 is in the sulfur-burning furnace 4 internal combustion; step 3, start the liquid sulfur pump 6, and send the liquid sulfur in the liquid sulfur tank 7 into the spray gun 5, and the spray gun 5 atomizes the liquid sulfur and sprays it into the sulfur furnace 4, and the atomized sulfur It is ignited by the ignition gun 1 and burned to produce SO 2 ; In the 4th step, close the ignition gun 1, and the atomized sulfur can be continuously burned in the sulfur furnace 4 to make SO 2 , while the temperature of the sulfur-burning furnace 4 continues to rise gradually to a normal operating temperature of 800-1200°C.

[0018] The proportioning of air and sulfur is proportioned according to the following formula:

[0019] m A =k*M S / 0.21

[0020] In the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com