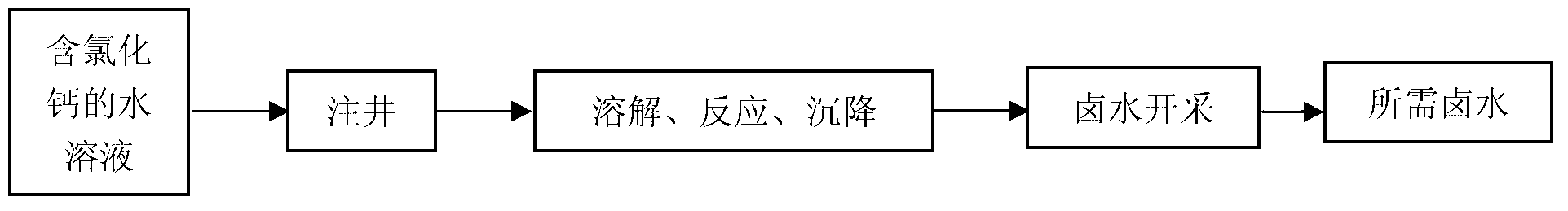

Application of calcium-chloride-containing aqueous solution in conversion exploitation of glauberite resource and conversion exploitation method of glauberite resource

A mining method, glauberite technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve problems such as no examples of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Put 1m 3 Contains CaCl 2 Inject a 20g / L solution (or aqueous solution) into a sodium sulfate type rock salt mine. The rock salt is in an environment of about 50 ℃ underground, and soluble salts such as sodium chloride and Glauber's salt are first dissolved in water (that is, the water contained in the solution). Glauber's salt is also decomposed into slightly soluble calcium sulfate and soluble sodium sulfate in the environment of calcium chloride solution. Calcium sulfate precipitates in the well, while sodium sulfate is dissolved in water. At this time, the dissolved sulfuric acid All the sodium reacts with the original calcium chloride in the solution to form slightly soluble calcium sulfate, which settles at the bottom of the well, and at the same time produces soluble sodium chloride, which is dissolved in water, and a small amount of Glauber's salt is dissolved as the brine flows. After 1 month enough time to settle, about 0.9m is mined 3 NaCl 316g / L, Na ...

Embodiment 2

[0059] Example 2: Put 1m 3 Contains CaCl 2 Inject a 40g / L solution into a sodium sulfate type rock salt mine. The rock salt is in an environment of about 50°C underground. Sodium chloride and Glauber's salt are first dissolved in the water. At the same time, Glauber's salt is also dissolved in the environment of calcium chloride solution. Liquor decomposes into slightly soluble calcium sulfate and soluble sodium sulfate. Calcium sulfate precipitates in the well, while sodium sulfate is dissolved in water. At this time, the dissolved sodium sulfate all reacts with the original calcium chloride in the solution to form Slightly soluble calcium sulfate, the sedimentation well is low, and at the same time, soluble sodium chloride is produced, which is dissolved in water, and the unreacted calcium chloride is mined along with the mineral brine. After 1 month enough time to settle, about 0.9m is mined 3 NaCl 302g / L, CaCl 2 18g / L bittern.

Embodiment 3

[0060] Example 3: Put 1m 3 Contains CaCl 2 Inject the 80g / L solution into the sodium sulfate type rock salt mine. The rock salt is at about 50℃ underground. Sodium chloride and Glauber's salt are dissolved in the water first. At the same time, Glauber's salt is also dissolved in the calcium chloride solution. Liquor decomposes into slightly soluble calcium sulfate and soluble sodium sulfate. Calcium sulfate precipitates in the well, while sodium sulfate is dissolved in water. At this time, the dissolved sodium sulfate all reacts with the original calcium chloride in the solution to form Slightly soluble calcium sulfate, the sedimentation well is low, and at the same time, soluble sodium chloride is produced, which is dissolved in water, and the incompletely reacted calcium chloride is mined with the mineral brine. After 1 month enough time to settle, about 0.9m is mined 3 NaCl 259g / L, CaCl 2 61g / L bittern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com