Spinning method for improving fiber carding straightening parallelism

A parallelism and fiber technology, applied in fiber processing, textiles and papermaking, deburring devices, etc., can solve the problems of reducing fiber modulus and stiffness, and achieve the effects of reducing stiffness, reducing damage, and improving straightening parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

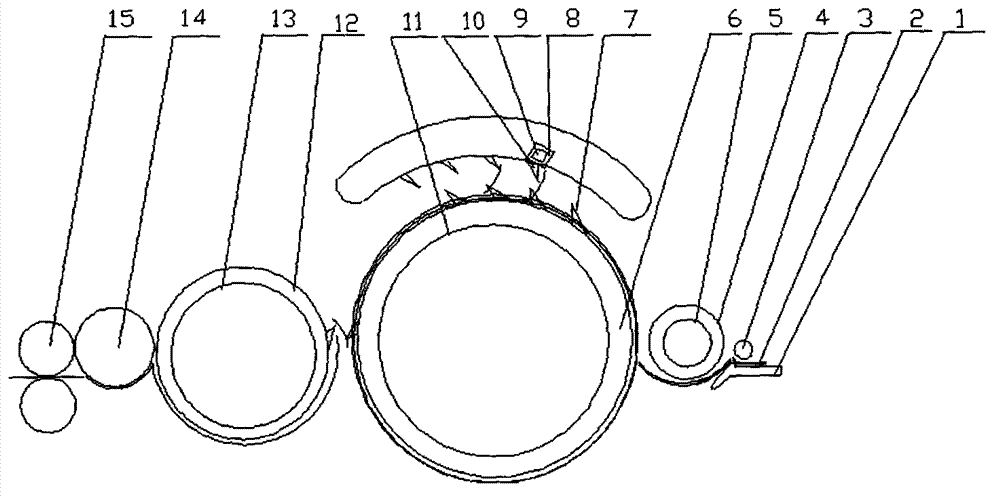

Image

Examples

Embodiment 1

[0019] The fiber is cotton fiber, and the treatment process is as described above, wherein the heat treatment temperature of the heat and humidity treatment device is 100°C, and the humidification aid is water. The working temperature of the first-stage heating device, the second-stage heating device, the third-stage heating device, and the fourth-stage heating device are all 120°C.

Embodiment 2

[0021] The fiber is soybean protein fiber, and the treatment process is as described above, wherein the heat treatment temperature of the heat and humidity treatment device is 70°C, the humidification assistant is an antistatic agent and water, and the weight ratio of the antistatic agent and water is 1:12. The working temperature of the first-stage heating device, the second-stage heating device, the third-stage heating device, and the fourth-stage heating device are all 70°C.

Embodiment 3

[0023] The fiber is wool fiber, and the treatment process is as described above. The heat treatment temperature of the heat and humidity treatment device is 90°C, the humidification assistant is antistatic agent, oil, water, and the weight ratio of antistatic agent, oil, and water is 1: 2:11. The working temperature of the first-stage heating device, the second-stage heating device, the third-stage heating device, and the fourth-stage heating device are all 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com