Method for preparing fabric with deodorizing function

A fabric and function technology, applied in the field of fabric preparation with deodorizing function, can solve the problems affecting the hand feel and wearing performance of the fabric, unsatisfactory washing fastness, etc., achieve good deodorizing health care function, keep fresh and comfortable, and feel happy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

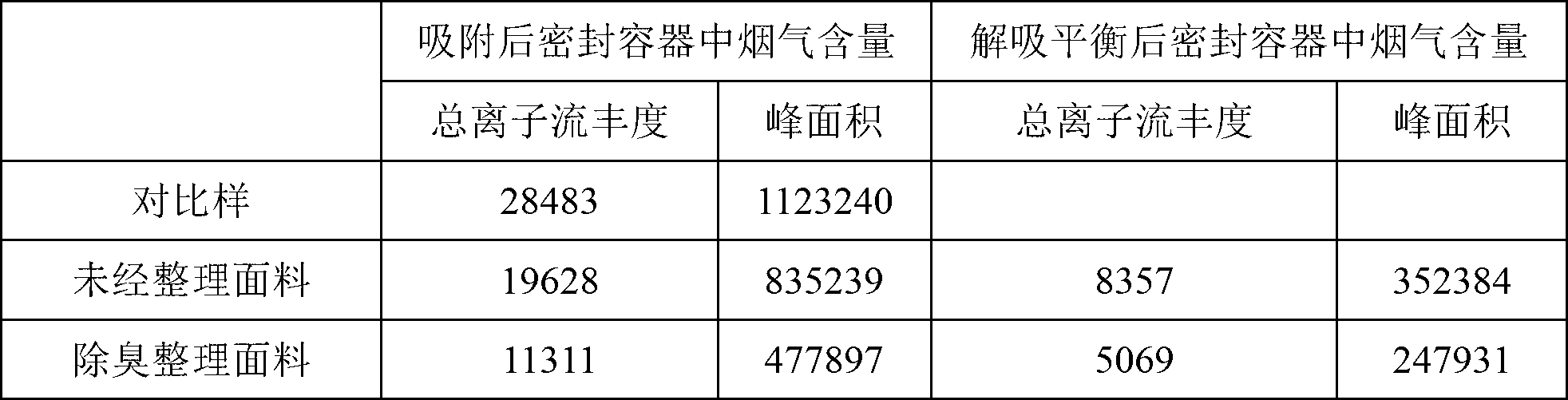

Examples

preparation example Construction

[0037] The preparation method of the fabric with deodorizing function of the present invention is specifically implemented according to the following steps:

[0038] Step 1, modification of β-cyclodextrin or preparation of sulfo-β-cyclodextrin:

[0039] 1) Measure concentrated sulfuric acid and β-cyclodextrin with a mass fraction of 70% to 90% respectively, the mass ratio between concentrated sulfuric acid and β-cyclodextrin is 5 to 6:1, pour the measured concentrated sulfuric acid Put the beaker with concentrated sulfuric acid into the beaker, then put the beaker with concentrated sulfuric acid into an ice bath, add the weighed β-cyclodextrin into the beaker with concentrated sulfuric acid at 0°C~5°C and stir for 1h~2h, Form a reaction solution, add distilled water to the reaction solution, the volume ratio of the reaction solution to distilled water is 1:15~25, and configure the reaction solution A;

[0040] 2) Take calcium carbonate and pour it into the reaction solution A...

Embodiment 1

[0067] Measure concentrated sulfuric acid and β-cyclodextrin with a mass fraction of 90% respectively, the mass ratio between concentrated sulfuric acid and β-cyclodextrin is 5.5:1, pour the measured concentrated sulfuric acid into a beaker, and then put the Put the beaker with concentrated sulfuric acid in an ice bath, add the weighed β-cyclodextrin into the beaker with concentrated sulfuric acid at 0°C and stir for 1 hour to form a reaction solution, pour the reaction solution into distilled water, The volume ratio of reaction liquid and distilled water is 1:25, is configured as reaction liquid A, gets calcium carbonate and pours in reaction liquid A, tests the pH value of reaction liquid A simultaneously to the pH of reaction liquid A is 7.0, stops adding calcium carbonate, Filter the reaction solution B, filter the generated calcium sulfate precipitate, wash the calcium sulfate precipitate with water, and then combine the washed calcium sulfate precipitate with the filtrate...

Embodiment 2

[0073] Measure concentrated sulfuric acid and β-cyclodextrin with a mass fraction of 80% respectively, the mass ratio between concentrated sulfuric acid and β-cyclodextrin is 5:1, pour the measured concentrated sulfuric acid into a beaker, and then put the Put the beaker with concentrated sulfuric acid in an ice bath, add the weighed β-cyclodextrin into the beaker with concentrated sulfuric acid at 3°C and stir for 2 hours to form a reaction solution, pour the reaction solution into distilled water, The volume ratio of reaction liquid and distilled water is 1:20, is configured as reaction liquid A, gets calcium carbonate and pours in reaction liquid A, tests the pH value of reaction liquid A simultaneously to the pH of reaction liquid A is 6.5, stops adding calcium carbonate, Filter the reaction solution B, filter the generated calcium sulfate precipitate, wash the calcium sulfate precipitate with water, and then combine the washed calcium sulfate precipitate with the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com