Measurement method capable of accurately controlling caterpillar gate embedded part coplanarity

A technology for precise control and measurement methods, used in measurement devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

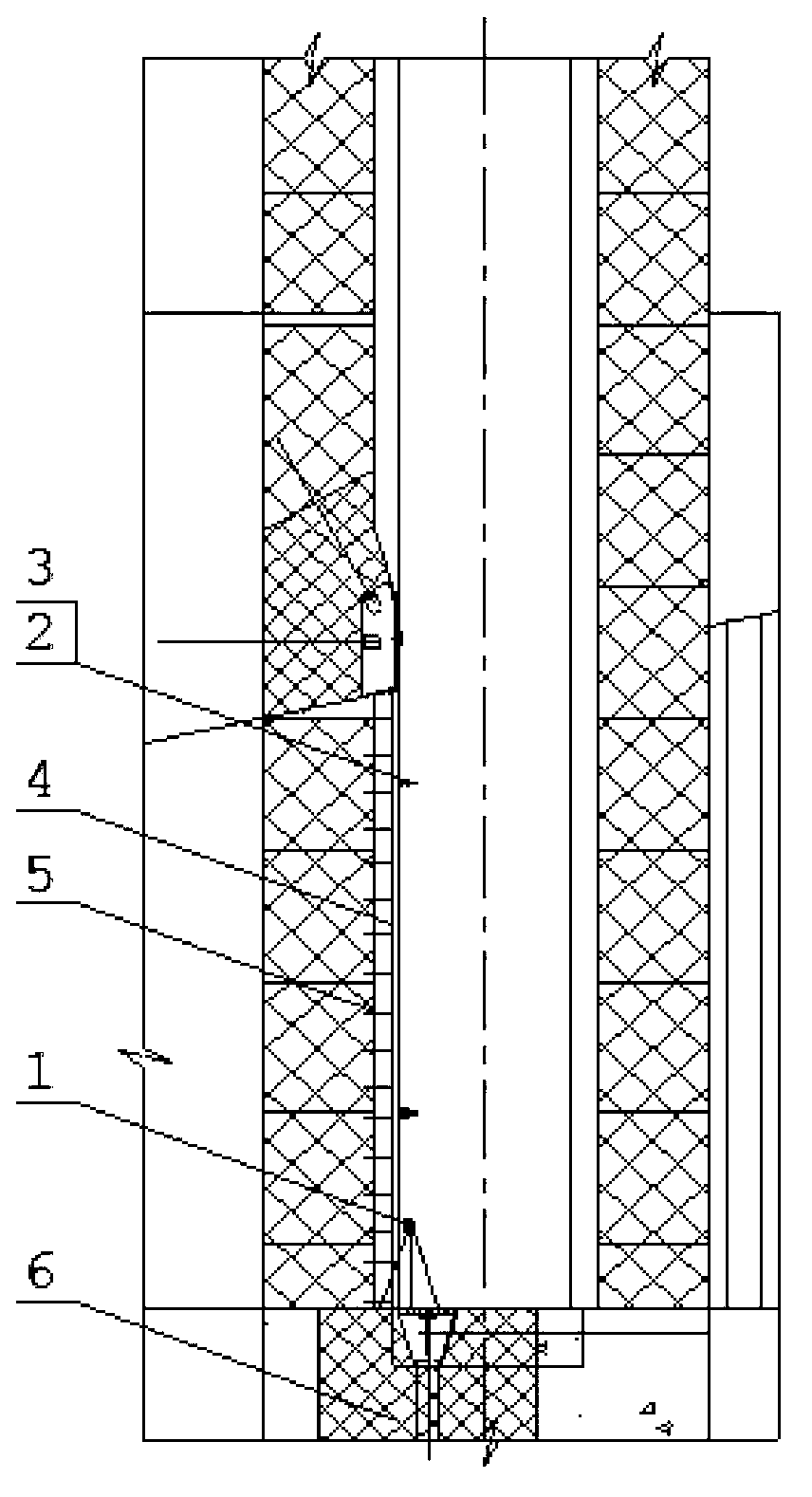

[0019] figure 1 It is a schematic diagram of the plane work of the method for accurately controlling the coplanarity measurement method of the sprocket gate embedded parts of the present invention, figure 2 It is a working schematic diagram of the facade of the method for measuring the verticality of the embedded part of the sprocket gate precisely controlled by the present invention. Such as figure 1 and figure 2 As shown, the inventive method needs the following instruments or tools: a theodolite or a total station 1, a vernier caliper 2, a magnetic base 3, an embedded part to be adjusted 4, a locking screw 5, an auxiliary pointer, etc.

[0020] The measurement method first requires the following preparations:

[0021] 1) Preparation and calibration of measuring instruments. It mainly includes the selection of theodolite or total station 1 that meets the measurement accuracy requirements of hydraulic engineering;

[0022] 2) Preparation of auxiliary measuring instrume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com