Horizontal conveying mechanism of defective take-out machine module

A technology of take-out machine and conveying motor, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problem of low efficiency of PCB board, achieve the effect of reducing investment cost, changing the current situation of a large number of laborers, and improving efficiency and cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the examples.

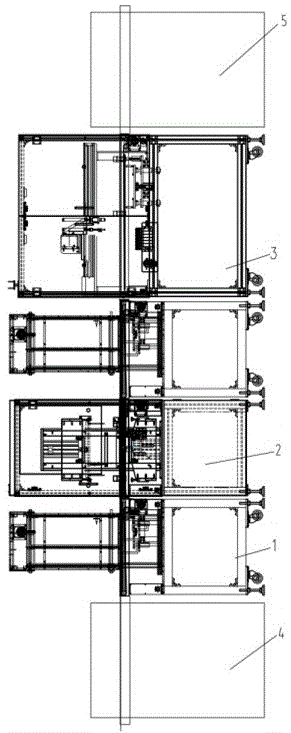

[0035] like figure 1 As shown, the entire PCB board flexible automatic inspection production line includes a feeding mechanism 4 , a defective product take-out machine module 1 , a PCB board automatic inspection machine module 2 , a PCB board good product automatic printing machine module 3 , and a feeding mechanism 5 .

[0036] Detect the quality of the PCB board according to the customer's needs. When the production line is working, the defective product take-out machine module 1 first receives the PCB board quality signal from the previous process, and the PCB board to be tested enters the defective product take-out machine module 1 through the feeding mechanism 4, and will not Good products and unqualified PCB boards are taken out, and good products continue to enter the PCB board automatic inspection machine module 2 to detect the PCB boards. Afterwards, according to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com