Special-shaped punch type waste material jumping prevention mold

A punch and waste technology, used in the field of molds, can solve the problems of product crushing, mold damage, low friction between waste and die, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

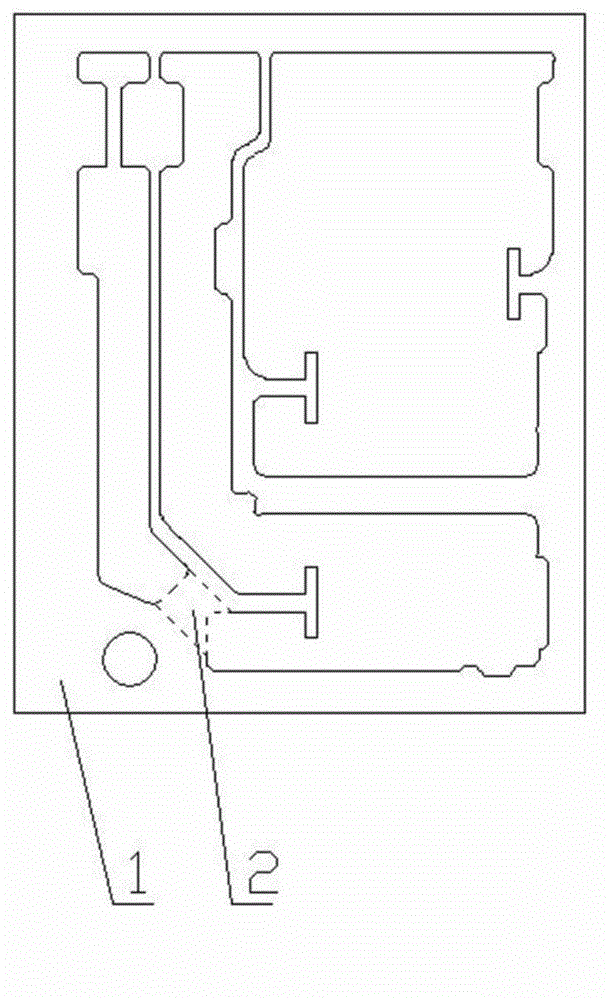

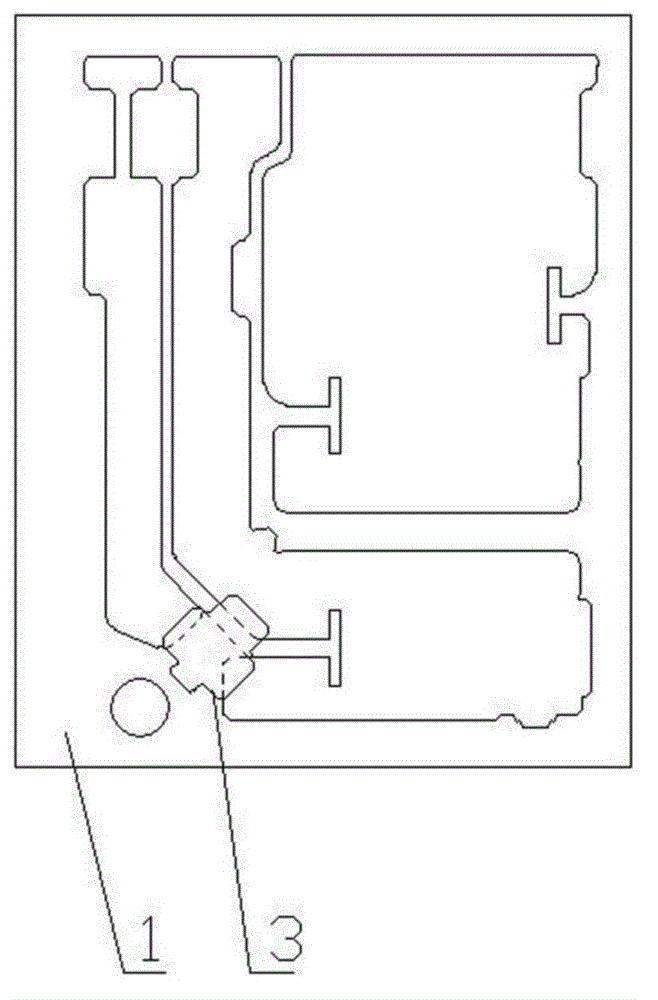

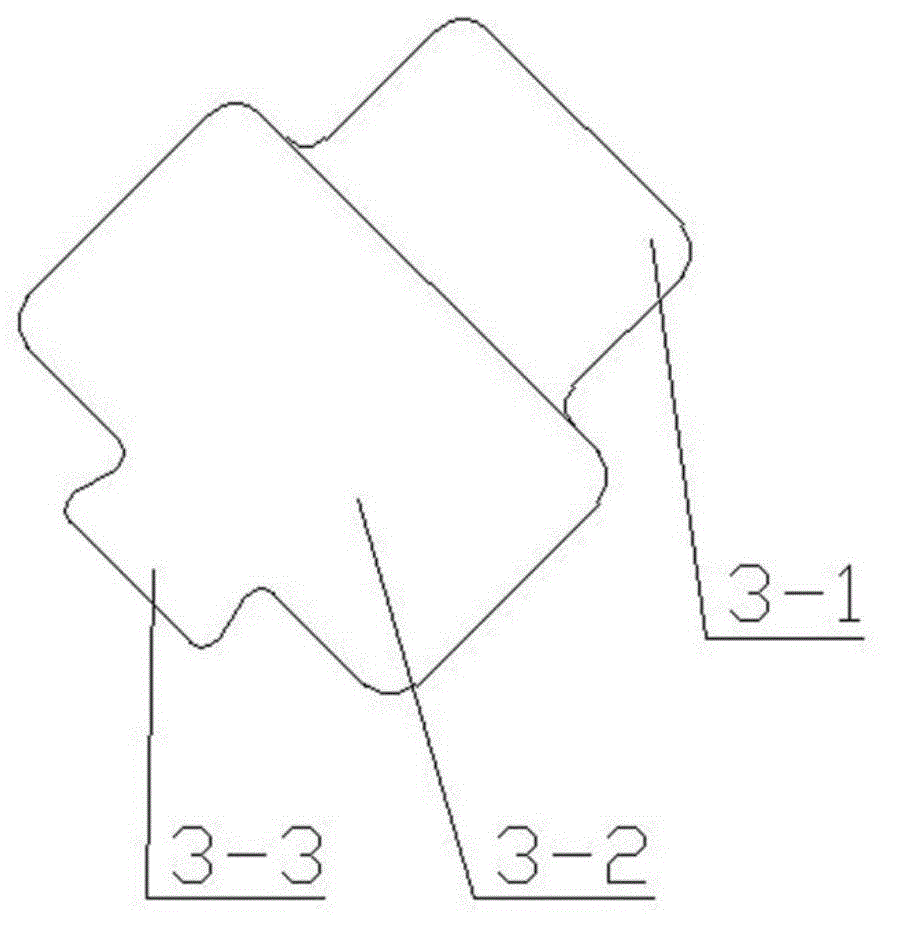

[0015] Such as image 3 A specific embodiment is shown, which includes a die and a punch 3, the die is provided with a cavity, the punch includes a punch body 3-2, and one side of the punch body 3-2 is provided with a boss 3 -3, the included angles between the two sides of the boss 3-3 and the plane on the punch body 3-2 where the boss 3-3 is located are all acute angles, so that the boss 3-3 is dovetail-shaped. The mold cavity of the die is corresponding to the shape of the punch main body 3-2, that is, the die has a dovetail-shaped groove.

[0016] The angle between the two sides of the boss 3-3 is preferably 30 degrees, so that the punched waste can form two sharp corners, and the two sharp corners are stuck in the mold cavity, and the waste is not easy to jump out.

[0017] The top surface of the boss 3-3 is preferably a plane, which is convenient for processing the punch 3.

[0018] On punch 3, preferably also adopt following structure: between the side surface and top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com