A method for preparing water purifying agent containing polyaluminum chloride from aluminum ash

A polyaluminum chloride and water purifying agent technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as low efficiency, many impurities, and difficult cleaning, and achieve high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare the water purifying agent containing polyaluminum chloride as follows:

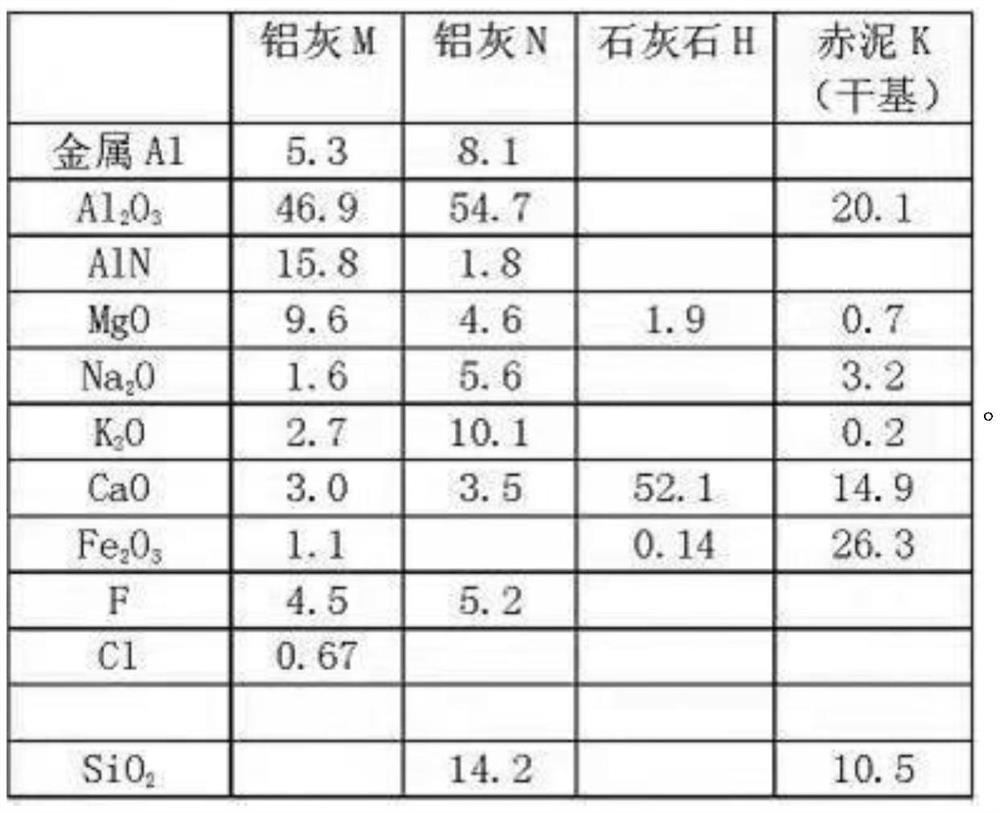

[0041] A. Take a secondary aluminum ash M1000kg (-10 mesh, see Table 1 for chemical composition) and limestone H800kg (-8 mesh, see Table 1 for chemical composition) and put it into a ball mill, mix ball mill for 5hr to -100 mesh, and the powder after grinding Calcined at 950°C for 3 hours in an oxidizing atmosphere of a small rotary kiln to obtain a roasted product;

[0042] B. In the 5000L reaction tank, add 3200kg of 20m% hydrochloric acid, start stirring, gradually put in slightly warm roasted raw material for reaction, gradually add 1600L of tap water, gradually increase the temperature of the slurry to 85°C, then control the temperature at 85-90°C, before overheating Appropriately reduce the temperature and feeding speed of the roasted raw material, the reaction time is 1.5hr, until the pH of the slurry filtrate is 3.8, Al 2 o 3 6.1m%, basicity 52;

[0043] C. The slurry in step B ...

Embodiment 2

[0048]Basically repeat the steps of Example 1 to prepare the water purifying agent containing polyaluminum chloride, the difference is that the ground powder in step A is roasted at 900°C in a small rotary kiln to obtain the roasted product; the tap water supplemented in step B slurry is replaced with Example 1 1600 L of washing water collected in step C washing the filter residue with water.

[0049] The roasted product obtained in the detection step A no longer contains metallic aluminum, aluminum nitride and calcium carbonate.

[0050] In the reaction of step B, the concentration and quantity of hydrochloric acid added, the amount of material charged by roasting, the control range of slurry temperature, and the reaction time are all the same, and the pH of the slurry filtrate is 3.6, and the Al 2 o 3 5.9m%, basicity 54; calculation of Al in the roasted raw material 2 o 3 The dissolution rate is 76%.

Embodiment 3

[0052] Basically repeat the steps of Example 1 to prepare the water purifying agent containing polyaluminium chloride, the difference is that the powder after step A is roasted in a small rotary kiln at 1000°C to obtain the roasted raw material; the supplemented tap water in step B is replaced by the step of Example 2 C filter residue washing water 1600L collected.

[0053] The roasted product obtained in the detection step A no longer contains metallic aluminum, aluminum nitride and calcium carbonate.

[0054] In the reaction of step B, the concentration and quantity of hydrochloric acid added, the amount of material charged by roasting, the control range of the temperature of the slurry, and the reaction time are all the same, and the pH of the slurry filtrate is 3.9, and the Al 2 o 3 6.2m%, basicity 51; calculation of Al in roasted raw materials 2 o 3 The dissolution rate is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com