Stirring device for calcium carbide pan waste heat recovery and application of stirring device

A stirring device and waste heat recovery technology, which is applied in the direction of stirring device, waste heat treatment, lighting and heating equipment, etc., can solve the problem of waste heat not being effectively utilized, and achieve the effect of improving waste heat recovery efficiency, increasing strength, and overall lightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

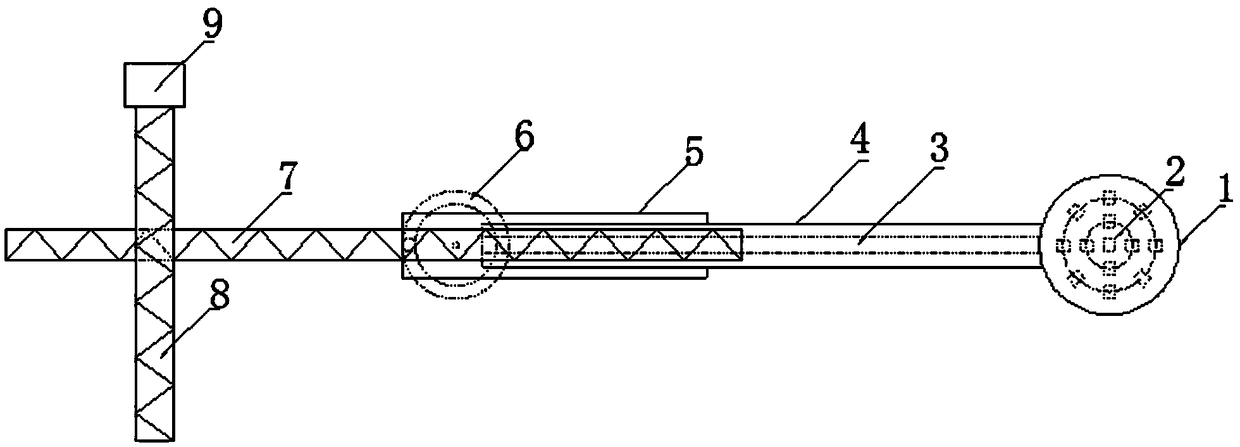

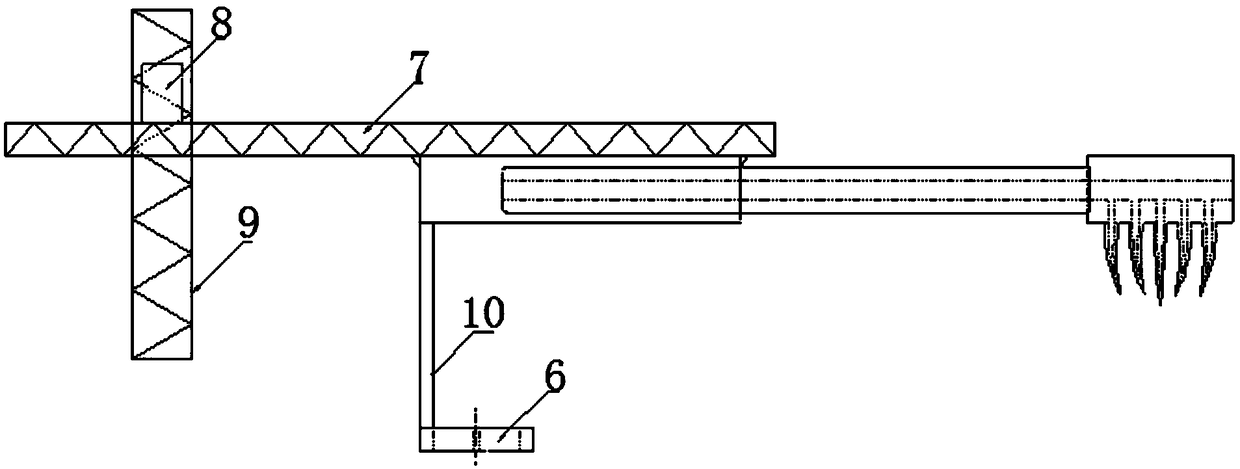

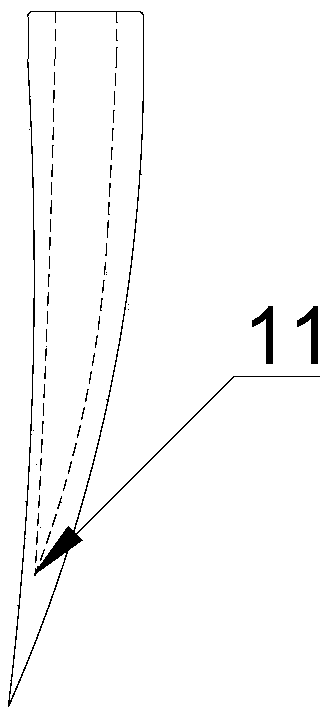

[0022] A stirring device for recovery of waste heat from calcium carbide pots is located in the high-temperature chamber of the tunnel kiln device for recovery of waste heat from calcium carbide pots. There are 10 sets in one set, corresponding to the 10 calcium carbide pots that come out of the kiln once in the tunnel kiln. It includes a stirring head 1, a stirring blade 2, a thermocouple 3, a stirring rod 4, a thermal insulation layer 5, a disc transmission device 6, a horizontal truss 7, a lifting truss 8, a vertical truss 9 and a connecting rod 10. The stirring blade 2 is located directly below the stirring head 1. The heat insulation layer 5 connects the stirring rod 4, the horizontal truss 7 and the connecting rod 10. The horizontal truss 7 can move horizontally in the track of the lifting truss 8, and the connecting rod 10 can be driven relative to the disc. The device 6 makes its own circular motion, and the horizontal truss 7 ensures that the stirring rod 4 moves horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com