Fiberglass Stereo Reinforced Lightweight Cement Strips

A glass fiber and three-dimensional reinforcement technology is applied in the field of glass fiber three-dimensional reinforced light-weight cement slats and glass fiber three-dimensional reinforced light-weight cement slats. The effect of workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

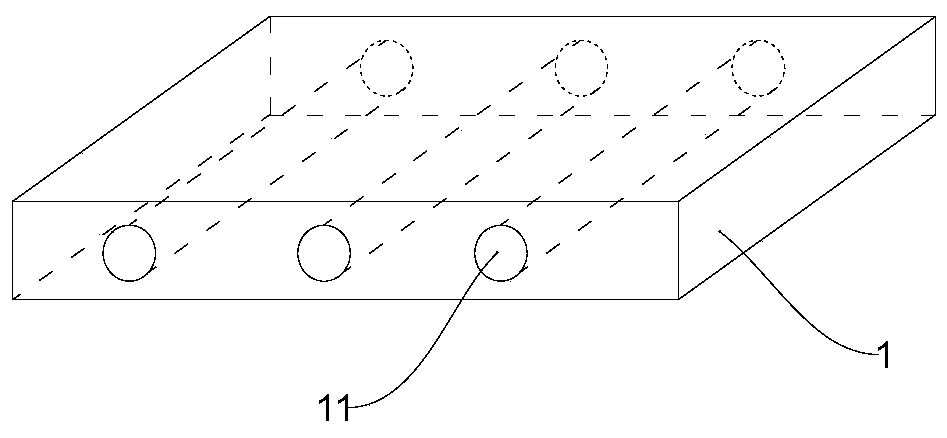

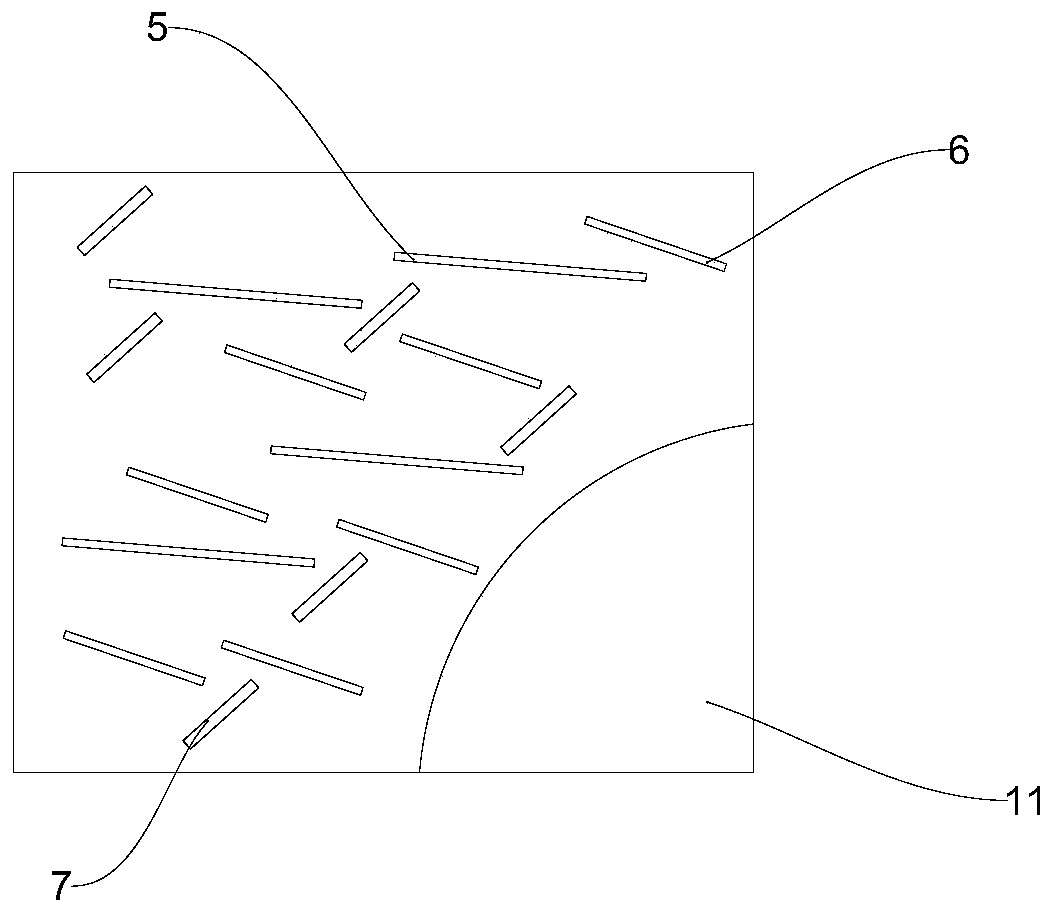

[0043] A glass fiber three-dimensionally reinforced lightweight cement strip, the cement strip is formed by a composite slurry casting mold, with glass fiber mesh cloth on both sides; the composite slurry includes the following raw materials in parts by weight: 12 Part of coal ash, 0.3 part of mixed glass fiber, 1 part of fine sand, 1 part of vermiculite, 1 part of ceramsite, 30 parts of water, 0.3 part of regulator, 0.1 part of micro-expansion agent, 37.5 parts of cement; wherein, the mixed glass The fibers are obtained by mixing glass fibers with lengths of 0.5cm, 1.6cm, and 2.6cm in a mass ratio of 3:1:1; the regulator includes the following raw materials in parts by weight: 10 parts of triethylene glycol dimethyl Acrylates, 2 parts Lauryl Methacrylate, 5 parts Trimethylolpropane Triacrylate, 5 parts Propylene Glycol Methyl Ether Acetate.

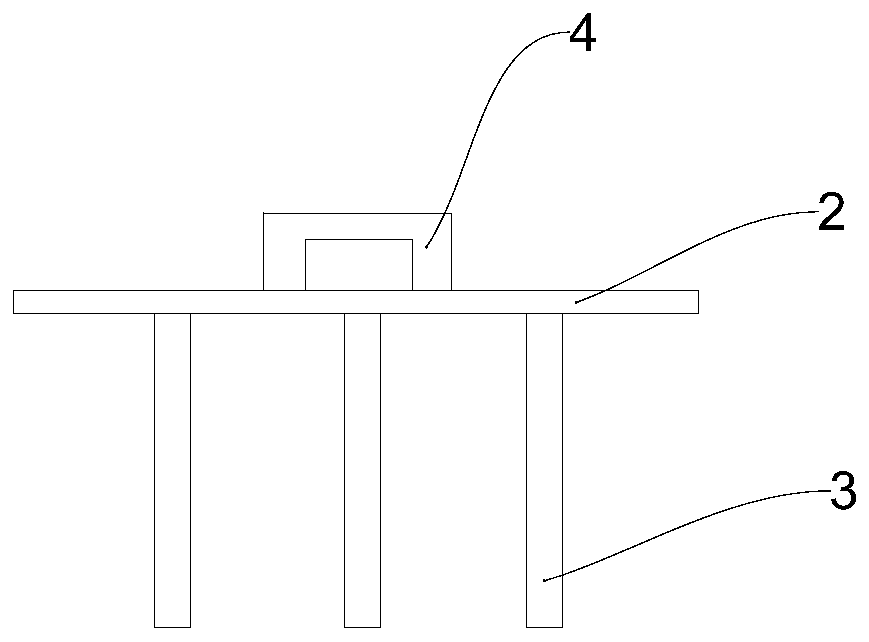

[0044] The processing technology of the glass fiber three-dimensionally reinforced lightweight cement batten comprises the following st...

Embodiment 2

[0051] A glass fiber three-dimensionally reinforced lightweight cement strip, the cement strip is formed by a composite slurry casting mold, with glass fiber mesh cloth on both sides; the composite slurry includes the following raw materials in parts by weight: 0.1 Parts of graphene, 12 parts of coal ash, 0.3 part of mixed glass fiber, 1 part of fine sand, 1 part of vermiculite, 1 part of ceramsite, 30 parts of water, 0.3 part of regulator, 0.1 part of micro-expansion agent, 37.5 parts of cement; , the mixed glass fiber is obtained by mixing glass fibers with lengths of 0.5cm, 1.6cm, and 2.6cm according to a mass ratio of 3:1:1; the regulator includes raw materials in the following parts by weight: 10 parts of triethyl Glycol Dimethacrylate, 2 parts Lauryl Methacrylate, 5 parts Trimethylolpropane Triacrylate, 5 parts Propylene Glycol Methyl Ether Acetate.

[0052] Described processing technology is consistent with embodiment 1.

Embodiment 3

[0054] A glass fiber three-dimensionally reinforced lightweight cement strip, the cement strip is formed by a composite slurry casting mold, with glass fiber mesh cloth on both sides; the composite slurry includes the following raw materials in parts by weight: 46 1 part of coal ash, 12 parts of perlite, 1 part of mixed glass fiber, 0.5 part of graphene, 8 parts of fine sand, 6 parts of vermiculite, 5 parts of ceramsite, 35 parts of water, 1.5 parts of regulator, 0.4 part of micro expansion agent, 75 parts of cement; wherein, the mixed glass fibers are obtained by mixing glass fibers with a length of 1.5cm, 2.5cm, and 3.5cm according to a mass ratio of 6:5:1; the conditioner includes the following raw materials in parts by weight : 15 parts of triethylene glycol dimethacrylate, 5 parts of lauryl methacrylate, 8 parts of trimethylolpropane triacrylate, 10 parts of propylene glycol methyl ether acetate.

[0055] The processing technology of the glass fiber three-dimensionally re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com