Magnetron sputtering coating production line for capacitive touch screens

A technology of magnetron sputtering coating and capacitive touch screen, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem of not being able to meet the requirements of different coating processes of various thin film materials at the same time, and the cost is high , different production lines and other problems, to achieve the effect of good sealing, high production efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

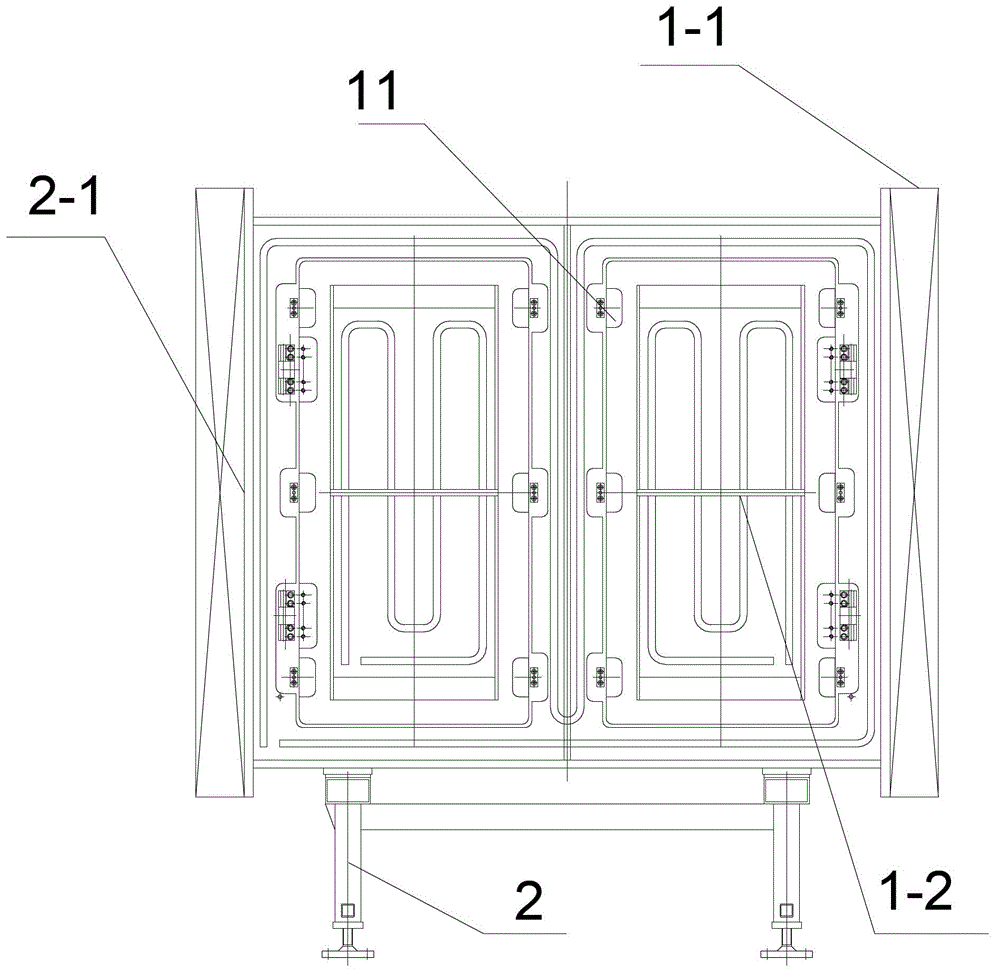

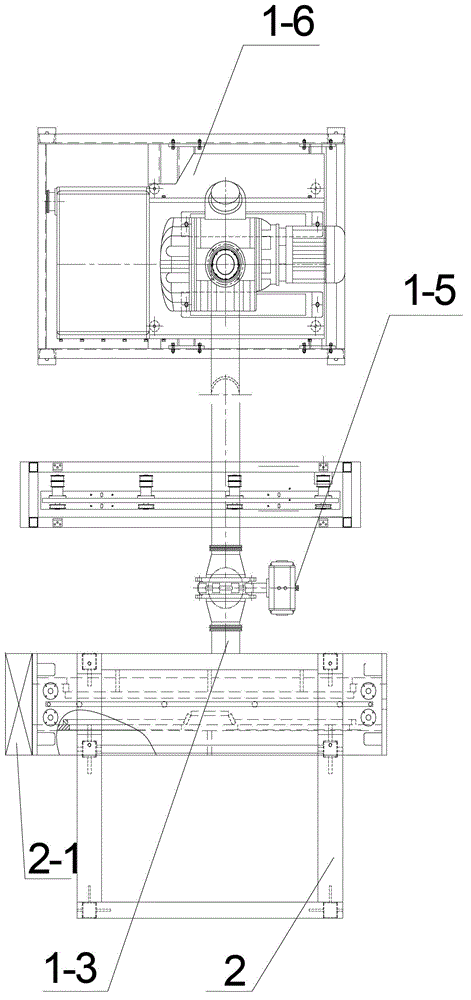

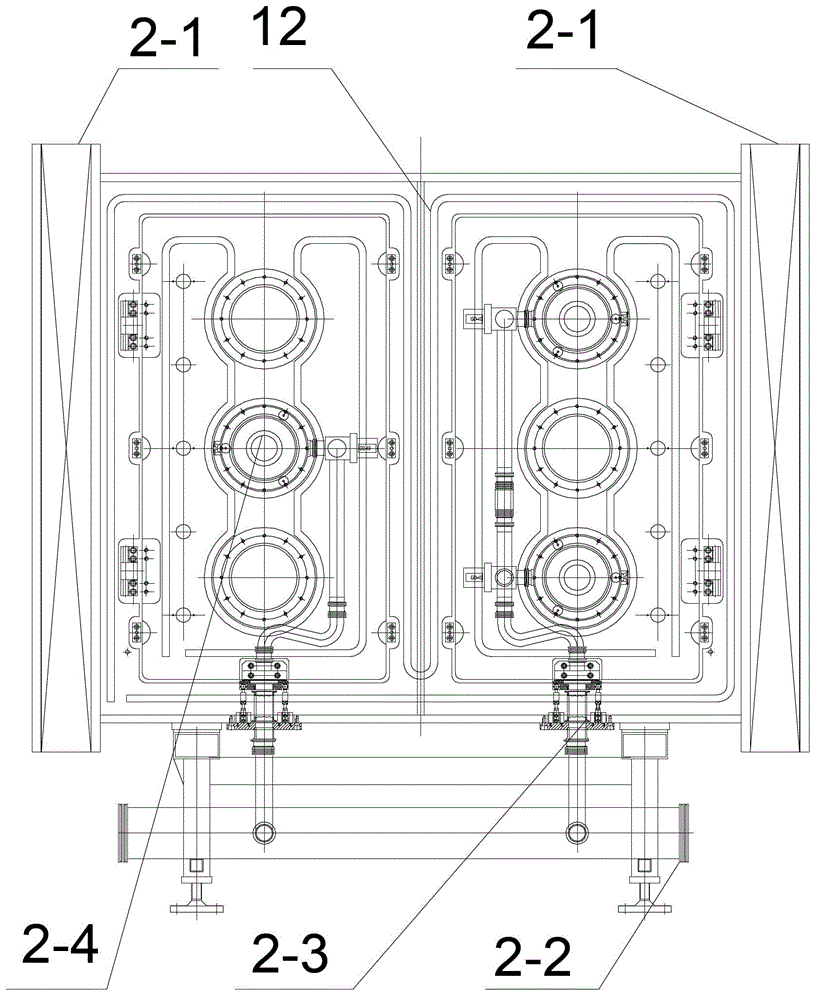

[0044] Depend on Figure 1~16 As shown, the present invention includes a vacuum coating cavity 1, a plurality of cavity supports 2 and a film return frame 3. The vacuum coating cavity 1 is installed on a plurality of cavity supports 2, and an internal conveying system is provided inside, and a vacuum The coating chamber 1 is divided into seven sections in turn: an inlet vacuum section 11, an inlet buffer vacuum section 12, an inlet transition vacuum section 13, a process coating vacuum section 14, an outlet transition vacuum section 15, an outlet buffer vacuum section 16, and an outlet vacuum section 17. Near the entrance of the vacuum section 11, a film feed frame 4 is provided, and a film feed translation platform 5 is provided near the film feed frame 4; Platform 7; described film back frame 3 is parallel with vacuum coating cavity 1, is arranged near vacuum co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com