Sliding gear type differential device

A technology for sliding gears and differentials, which is applied in differential transmissions, gear lubrication/cooling, belts/chains/gears, etc. It can solve problems such as poor steering flexibility, high prices, and impacts on teeth and cogs, and achieve transmission The effect of reliable driving torque, simple operation and flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

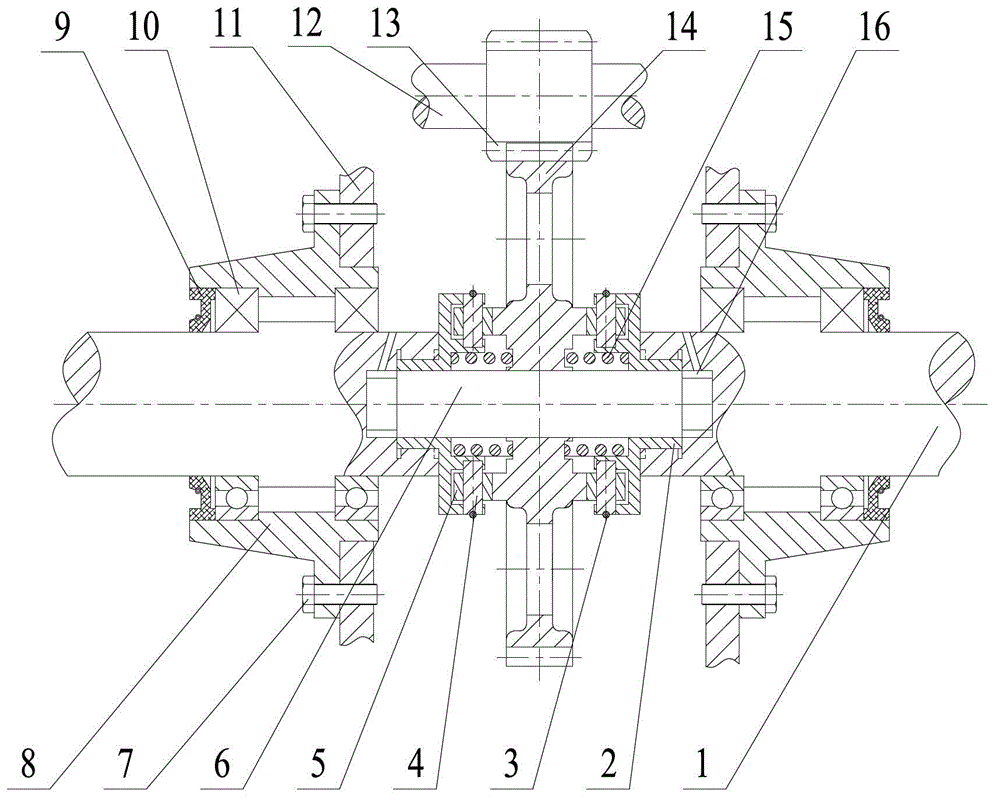

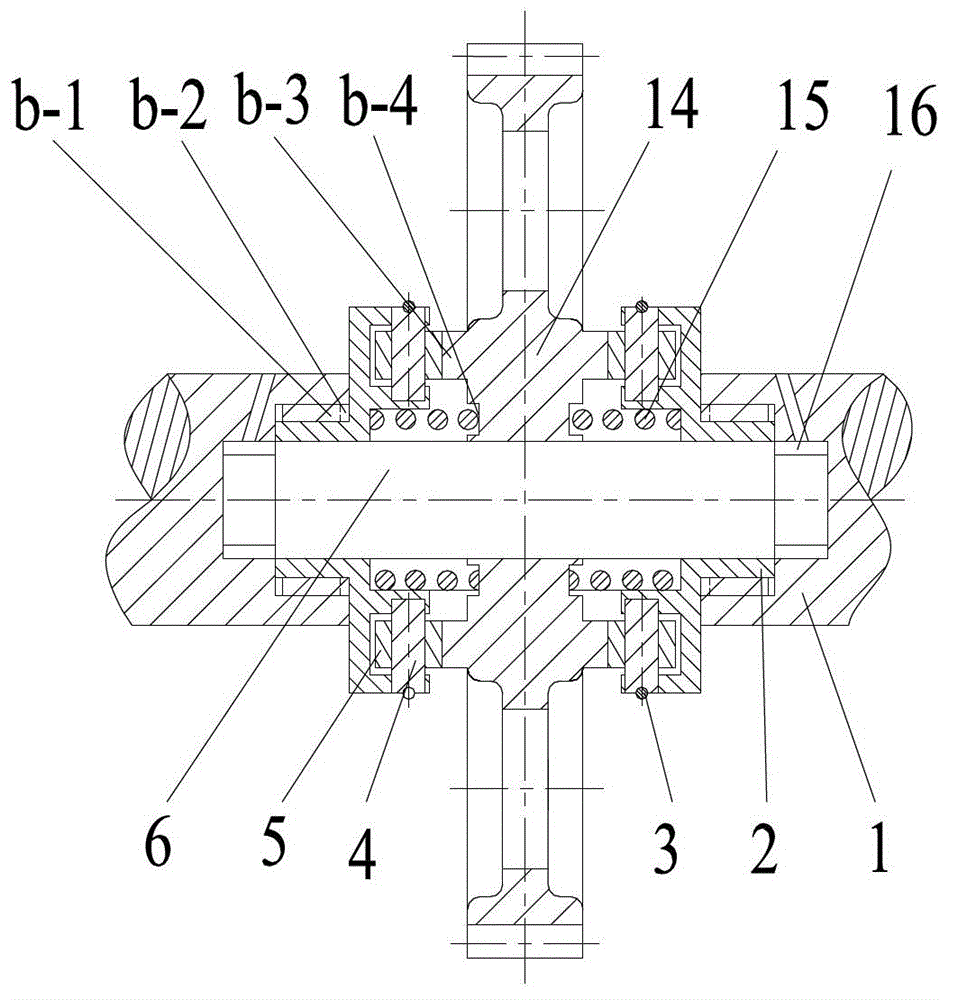

[0025] see figure 1 , a sliding gear differential, comprising a power output shaft 1, a roller frame 2, a roller shaft clamp 3, a roller shaft 4, a roller 5, a support shaft 6, bolts 7, an end cover 8, an oil seal 9, a bearing 10, Box 11, power input shaft 12, power input gear 13, sliding gear 14, spring 15, sliding sleeve 16;

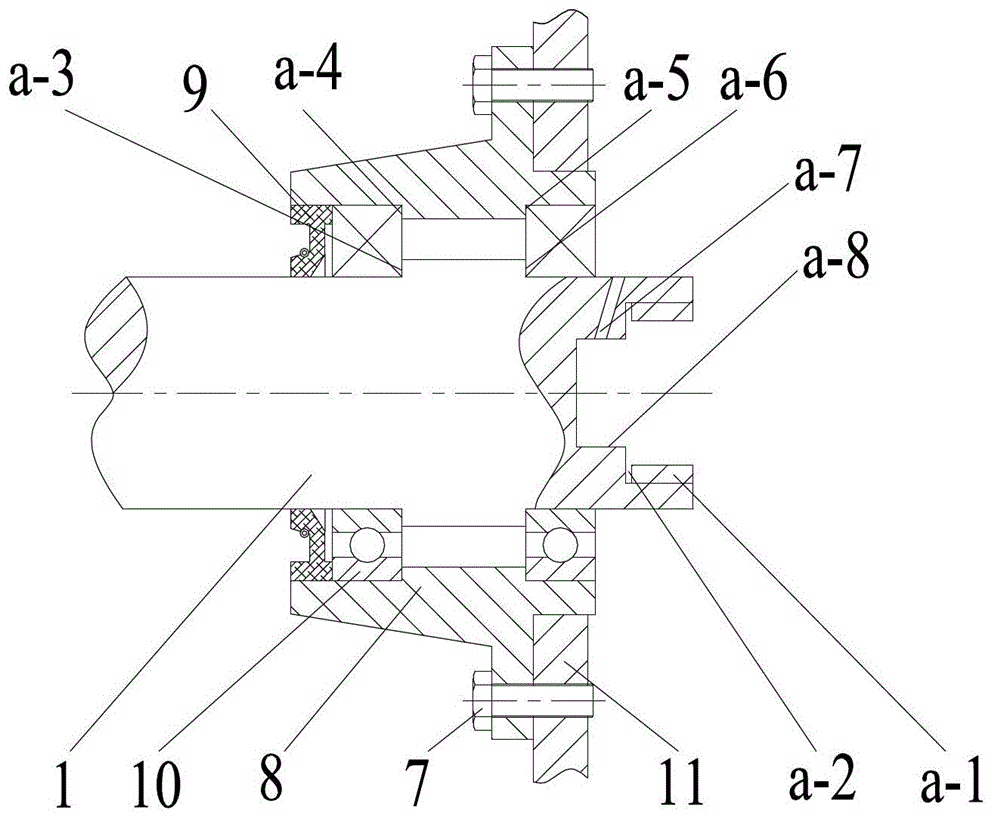

[0026] see figure 1 with figure 2 , the end cover 8 is fixed on the box body 11 through the bolt 7, the power output shaft 1 is positioned on the end cover 8 through the bearing 10, and the oil seal 9 is installed on the outer end of the end cover 8; the power output shaft 1 is designed with a step a -3 and a-6, its width is equal to the steps a-4 and a-5 on the end cover 8, one of the bearings 10 is installed on the steps a-3 and a-4, and the other is installed on the steps a-5 and the steps At a-6, this struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com