Method for determining corresponding relation between absolute filter precision and bubble breaking point

A technology of filtration accuracy and corresponding relationship, which is applied in the direction of measuring devices, instruments, etc., can solve the problems that the tested filter and filter element cannot be used normally, the test equipment is complicated, and the test cost is high, so as to simplify the test method, the method is feasible, and the implementation is easy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

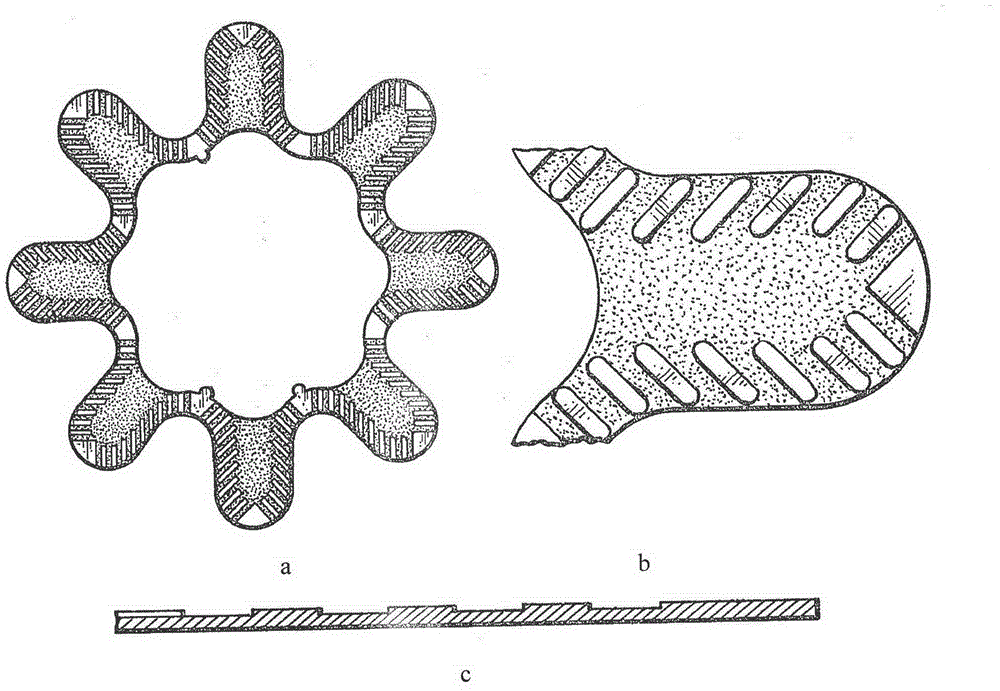

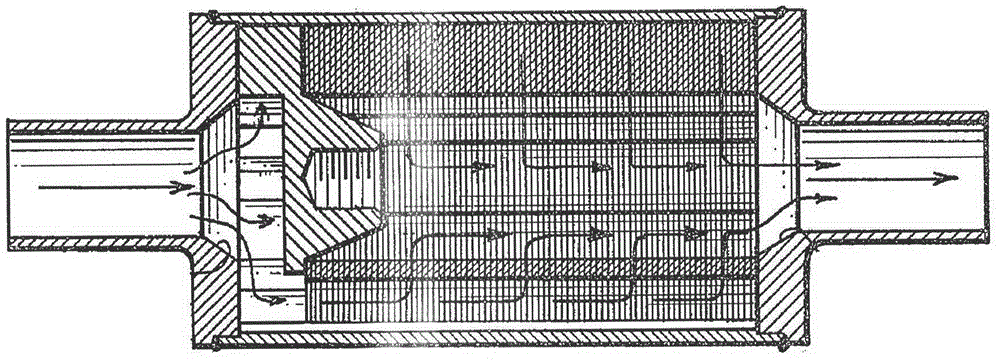

[0024] The method for determining the corresponding relationship between the filter absolute filtration precision and the bubble breaking point involved in the present invention is applicable to the laminated filter using the groove on the filter sheet as the filter flow channel (see figure 2 , image 3 ). By measuring the maximum depth of the flow channel on the filter sheet, the absolute filtration accuracy of the filter sheet is determined, and the designed test method is used to complete the data measurement of the bubble break point, and the corresponding relationship between the absolute filter accuracy of the filter and the bubble break point is determined by curve fitting.

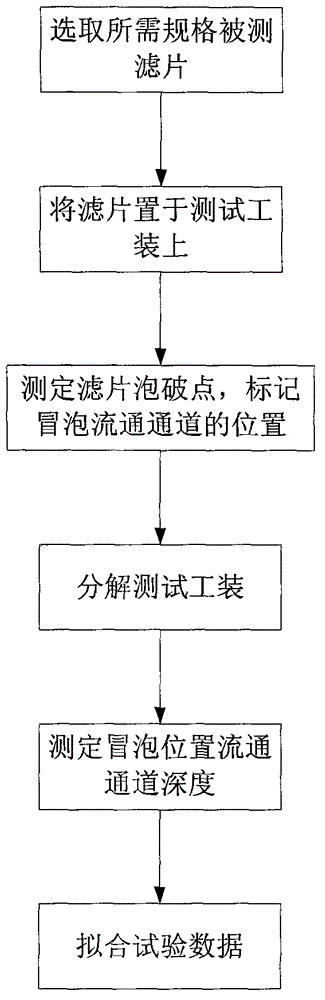

[0025] Such as figure 1 Shown, concrete steps of the present invention are as follows:

[0026] (1) According to the test needs, select the tested filters of various specifications.

[0027] (2) According to Figure 4 As shown in the principle, the tested filter 1 is installed on the test tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com