Automatic test system and test method for thermoelectric forces of thermocouple wires

A thermocouple wire, automatic detection technology, applied in the direction of using digital measurement technology for measurement, measurement device, measurement of heat, etc. Uniformity fluctuation and other problems, to achieve the effect of high degree of automation, high accuracy and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

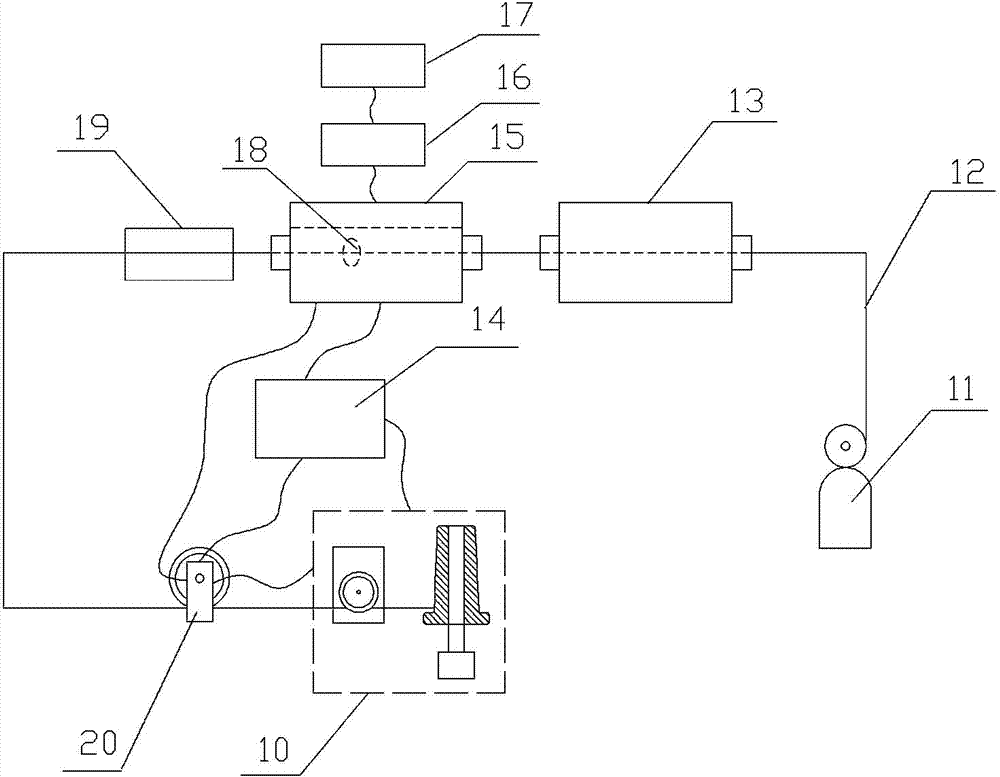

[0055] Rewinding device 10, pay-off device 11, preprocessing device 13, control system 14, test unit 15, signal acquisition system 16, computer 17 equipped with thermoelectric potential test and analysis system, meter counter 20

[0056] The size of the Bakelite conical cylinder of the pay-off device is: the diameter of the upper end of the cylinder is ?110mm, the diameter of the bottom end of the cylinder is ?120mm, and the height of the cylinder is 120mm; the pretreatment device: the inner diameter of the furnace tube is ?20mm, the outer diameter is ?30mm, and the length is 1000mm , the furnace tube heating wire is ?1.0mm PtRh20 alloy wire, and the temperature control thermocouple is a first-class standard PtRh10-Pt thermocouple; the test unit: the furnace tube specification is ?20 mm in inner diameter, ?30 mm in outer diameter, and 20 mm in length. The highest temperature control is 1500°C, the temperature control thermocouple is a first-class standard PtRh10-Pt thermocouple...

Embodiment 2

[0063] The heating wire of the furnace tube in the pretreatment device is made of PtRh30 alloy wire, the maximum temperature control temperature of the furnace tube is 1600°C, and the interval between rewinding and wiring is 1 min. Others are the same as in Example 1. This method is used to test the uniformity of 400 meters of R-type PtRh13-Pt thermocouple wire. The uniformity of the whole coil is good. After testing, it meets the standard requirements.

[0064] The device can be used for S (platinum rhodium 10-platinum), R (platinum rhodium 13-platinum), B (platinum rhodium 30-platinum rhodium 6) and other thermocouple wire thermoelectric potential uniformity detection.

Embodiment 3

[0066] The tubular furnace of the pretreatment device is iron-chromium-aluminum alloy wire (0Cr21A16Nb, 0Cr27A17Mo2, etc.), the temperature control temperature of the furnace tube is 800 ° C, and the time between rewinding and wiring is 5 minutes. Others are the same as in Example 1. The method is used to test the uniformity of 200 meters of K-type thermocouple wire. The uniformity of the whole coil of thermocouple wire is good. After testing, it meets the standard requirements.

[0067] The device can be used for N-type (nickel-chromium-silicon-magnesium), K-type (nickel-chromium-nickel-silicon), E-type (nickel-chromium-copper-nickel), J-type (iron-copper-nickel), T-type (copper-nickel-nickel) Copper nickel) and other thermocouple wire thermoelectric potential uniformity detection.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap