Method for using intelligent insulating tool cabinet

An insulating tool and intelligent technology, which is applied in the direction of manufacturing tools, tool storage devices, and controlling multiple variables at the same time, can solve the problems of slow drying process, chaotic placement of tools, and water mist on the surface, so as to achieve good sealing performance and convenience Convenient for transportation and observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

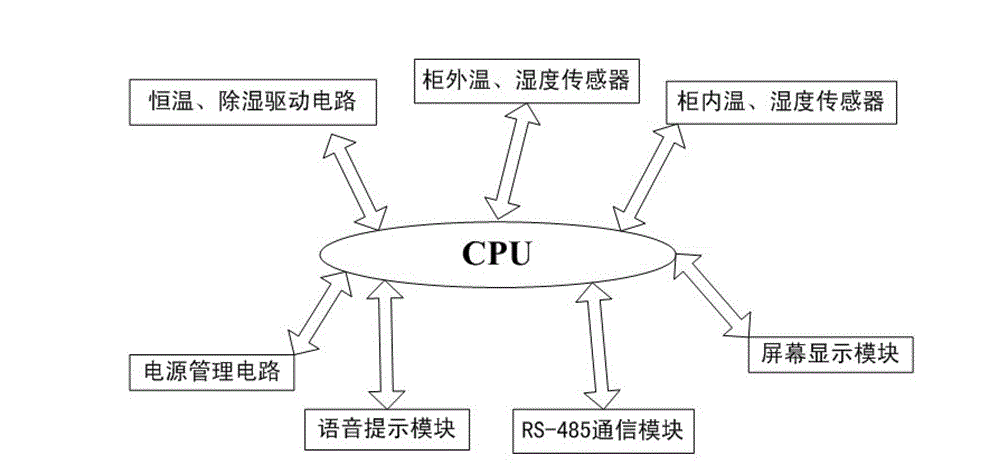

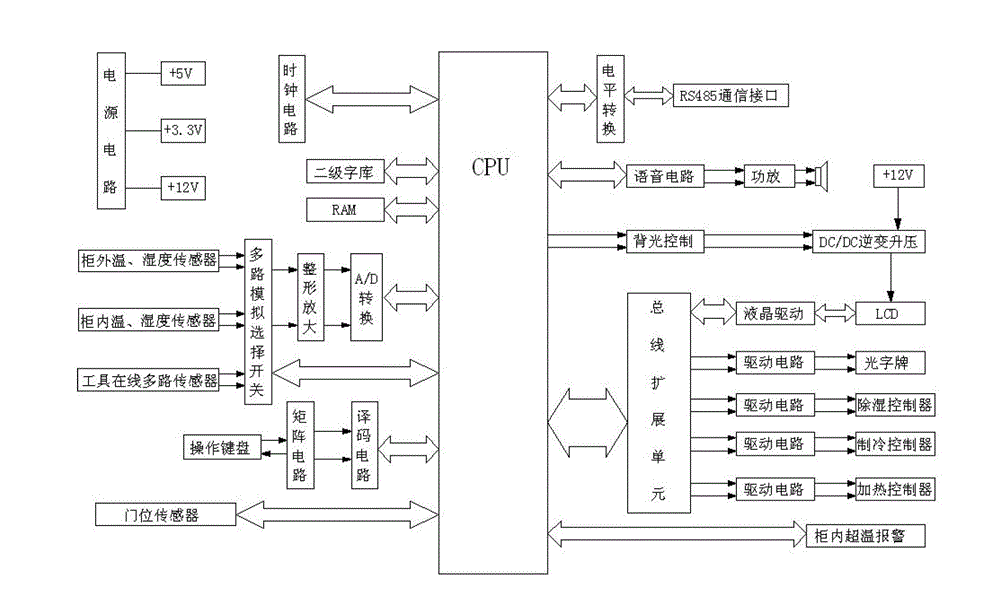

[0030] See Figures 1 to 2 , the intelligent insulated tool cabinet of this embodiment includes: temperature and humidity sensors outside the cabinet, temperature and humidity sensors inside the cabinet, a screen display module, an RS-485 communication module; a voice prompt module, a power management circuit, a constant temperature dehumidification drive interface, and The CPU connected to the above components, the safety tool cabinet, the electronic dehumidifier, the intelligent air conditioner, and the operation panel.

[0031] The temperature and humidity sensors inside and outside the cabinet collect the temperature and humidity values outside the cabinet and send them to the controller. The electrical parameters are: power supply voltage: DC5V±5%, current consumption: about 0.8 mA, operating temperature range: -50°C-90°C, Humidity range: below 2%RH-99%RH (non-condensing), temperature measurement range: -25°C-80°C, humidity measurement range: 0%RH-99%RH, temperature acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com