Touch display driving method for embedded touch screen

An embedded touch screen and touch-driven technology, which is applied in the fields of optics, instruments, and electrical digital data processing, etc., can solve the problems of touch screens not working normally, complex implementation, and poor touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

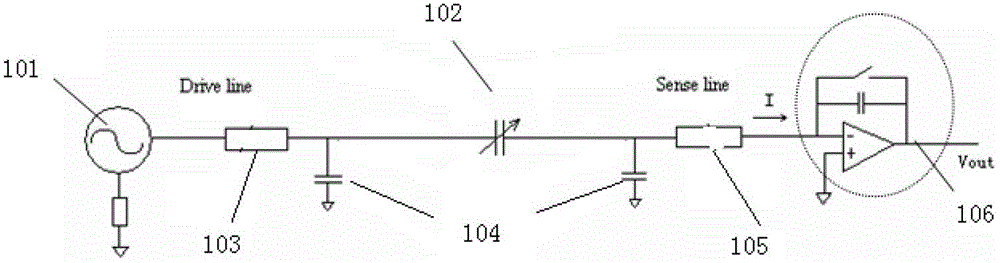

Method used

Image

Examples

Embodiment 1

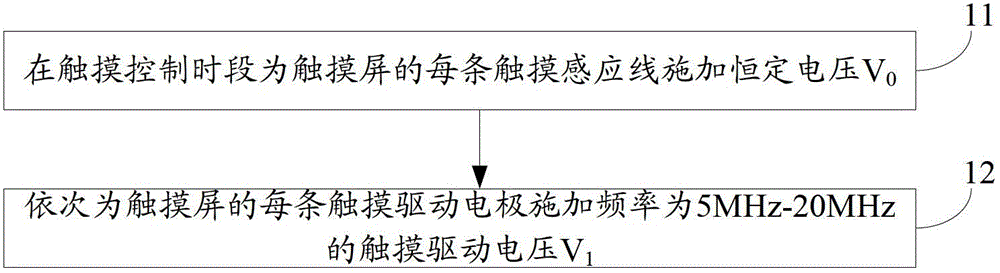

[0069] Take gate lines as touch driving electrodes as an example.

[0070] see Figure 5 , The touch screen provided by the embodiment of the present invention includes: a plurality of grid lines 1 arranged horizontally, the grid lines are arranged on the first substrate 2, and also includes: a plurality of touch sensing electrodes 3 arranged vertically, and the driving IC is the touch sensing electrode 3 Apply a constant voltage V 0 , and apply a touch drive voltage V for gate line 1 1 An electric field is formed between the touch sensing electrodes 3 and the grid lines 1 , and slits are provided between adjacent touch sensing electrodes 3 to achieve better touch effect and touch accuracy.

[0071] The touch sensing electrodes 3 can be arranged on the first substrate 2 or on the second substrate ( Figure 5 not reflected in).

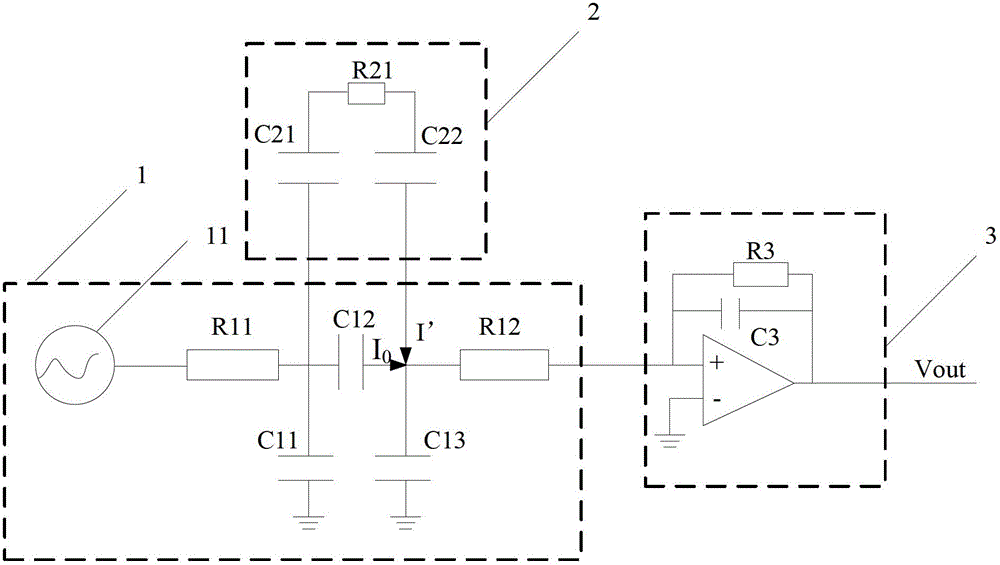

[0072] The following describes how to apply a voltage V of a certain frequency to the touch drive electrode (gate line) without affecting the norm...

Embodiment 2

[0083] Figure 5 The shown touch driving electrodes may be touch driving electrodes independent of the grid lines, for example: conductive electrodes additionally arranged on the first substrate 2 may be used as touch driving electrodes, and the conductive electrodes may be arranged on a different layer from the grid lines, and The non-display area arranged laterally between the pixel units avoids affecting the aperture ratio of the pixels.

[0084] When the touch drive electrodes are independent touch drive electrodes arranged horizontally, a voltage V of a certain frequency is applied to each touch drive electrode of the touch screen. 1 ,Specifically:

[0085] A touch driving voltage is applied to the touch driving electrodes through a touch driving circuit independent of the display driving circuit.

[0086] To sum up, the embodiment of the present invention provides an in-cell touch screen touch display driving method, which applies a constant voltage V to each touch sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com