Heating control method for electrical cooking appliance

A control method and heating control technology, applied to auxiliary controllers with auxiliary heating devices, using electric methods for temperature control, cooking utensils, etc., can solve problems such as insufficient control, large temperature fluctuations, and low control accuracy , to avoid easy damage and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

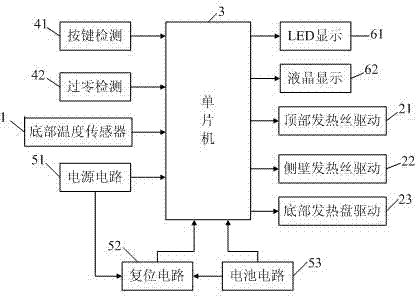

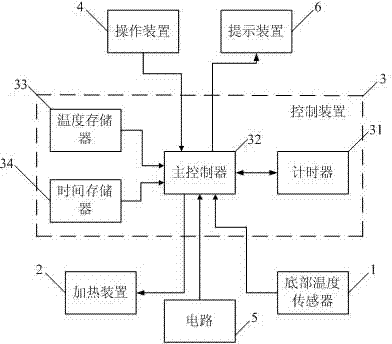

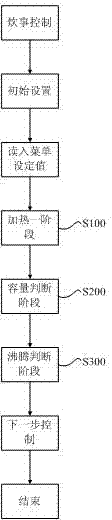

[0027] The present invention is generally applied to computer-controlled rice cooker products, and its structural schematic diagram is as follows: figure 1 , figure 2 As shown, the computer electric rice cooker includes a bottom sensor 1, a heating device 2, a control device 3, an operating device 4, a circuit 5 and a prompt device 6; the heating device 2 includes a top heating wire 21, a side wall heating wire 22, a bottom heating wire Disk 23; said control device 3 namely single chip microcomputer comprises timer 31, master controller 32, temperature memory 33 and time memory 34; said operating device 4 comprises key detection 41 and zero-crossing detection 42; said circuit 5 comprises power supply circuit 51 . A reset circuit 52 and a battery circuit 53 ; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com