Integrity detection instrument for microfiltration membrane filter

A filter and integrity technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems affecting measurement accuracy and actual volume reduction, so as to improve accuracy, avoid accumulation, Design convenient and fast effects

Active Publication Date: 2014-08-27

上海一鸣过滤技术有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, after use, the moisture in the gas source will usually remain in the reference tank, resulting in a decrease in the actual volume of the tank and affecting the accuracy of the measurement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

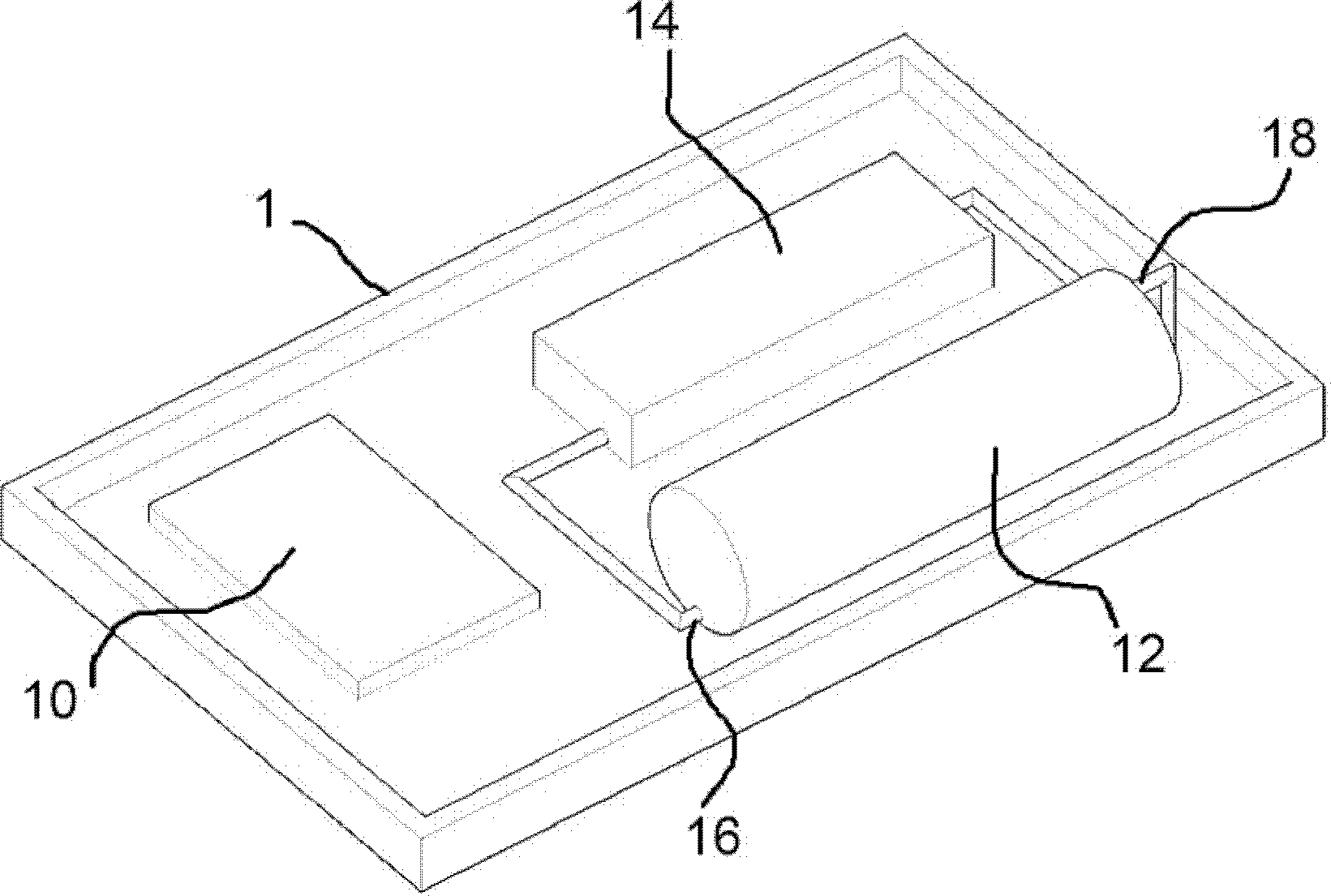

[0023] like figure 1 As shown, an integrity detector for a microfiltration membrane filter includes a data processing unit 2 , a reference tank 5 , a pneumatic element 3 and a bottom plate 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an integrity detection instrument for a microfiltration membrane filter. The detection instrument includes a data processing unit, a pneumatic component, a reference tank and a bottom plate. The data processing unit, the pneumatic component and the reference tank are fixed on the bottom plate. The data processing unit is connected to the pneumatic component, which is in connection with the reference tank. Compared with the prior art, the invention has the advantages of high detection precision, high intelligent degree and the like.

Description

technical field [0001] The invention relates to a filter detector, in particular to an integrity detector for a microfiltration membrane filter. Background technique [0002] When the filter integrity detector is tested, it first needs to measure the upstream volume of the filter, and then measure the pressure decay value in the filter, and calculate the gas flow rate of the filter. [0003] To automatically measure the upstream volume of the filter, generally a reference tank with a known volume is installed inside the detector, and the upstream volume of the filter is measured through a comparative test. [0004] However, after use, the moisture in the gas source usually remains in the reference tank, resulting in a decrease in the actual volume in the tank and affecting the accuracy of the measurement. Contents of the invention [0005] The object of the present invention is to provide an integrity tester for microfiltration membrane filters with high test accuracy and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D65/10

Inventor 王鑫刘震王阳周晟磊

Owner 上海一鸣过滤技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com