Programming system and method for industrial robot

An industrial robot and programming system technology, applied in the field of CNC machining, can solve the problems of reducing the efficiency of industrial robots and CNC machine tools, increasing the difficulty of processing preparation stages, etc., to achieve scalability, generalization, and simplification of programming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

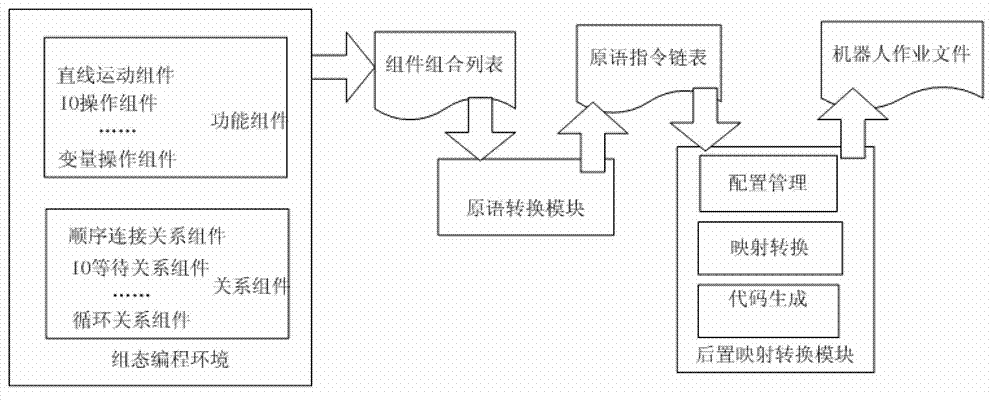

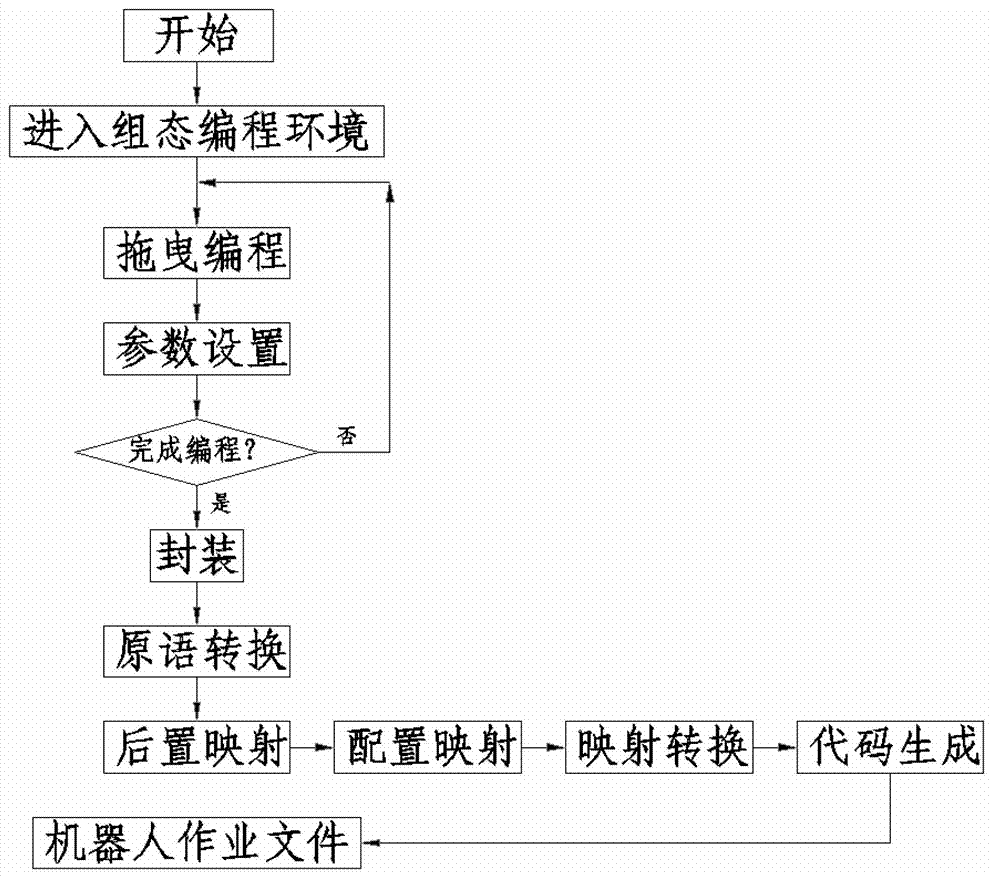

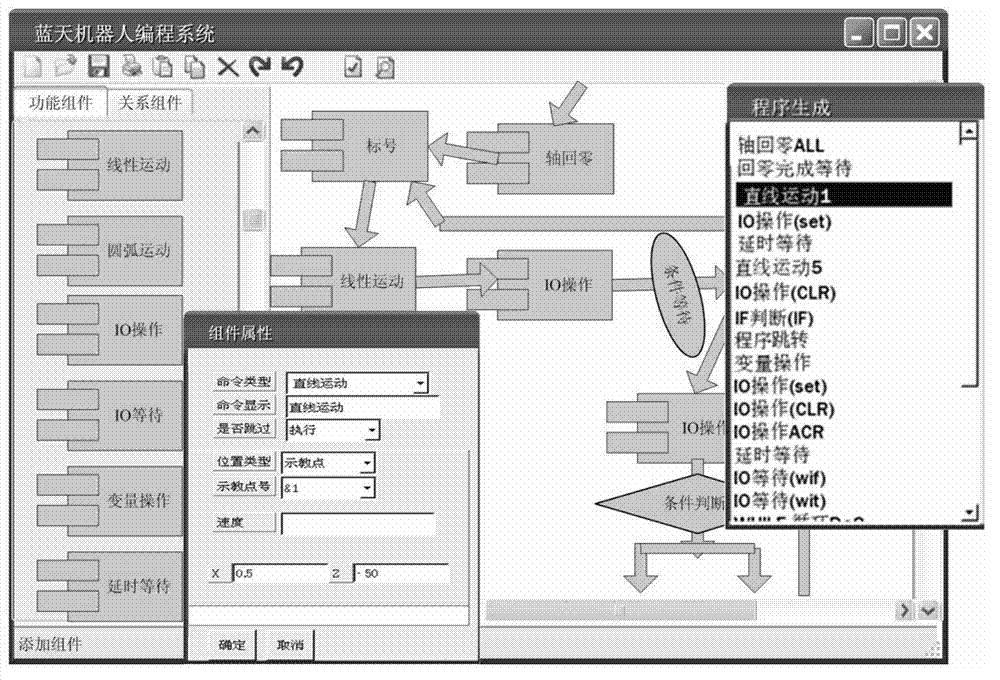

[0035] The programming system of the present invention is applied as figure 1The system structure shown mainly includes configuration programming environment module, primitive conversion module and post-mapping conversion module. The configuration programming environment is used to establish a component combination list, and the primitive language conversion module automatically generates a primitive instruction chain list, and then generates the job file of the specified robot controller through the post-map conversion module.

[0036] The above-mentioned configuration programming environment module replaces the traditional instruction programming environment on the basis of completely retaining the realization function of the existing industrial robot programming instructions to realize the job programming of industrial robots.

[0037] The above-mentioned primitive conversion module is a standard primitive conversion module inside the programming system, which converts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com