Wire harness connection and installation structure

A technology of installation structure and wire harness, which is applied in the direction of transportation and packaging, circuit or fluid pipeline, vehicle parts, etc., can solve the problems of inconvenient detection and maintenance of electrical components, affecting the airtightness of the structure, complicated operation, etc., and achieves the convenience of wiring harness connection and installation structure, improve the efficiency of disassembly and assembly, and the effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

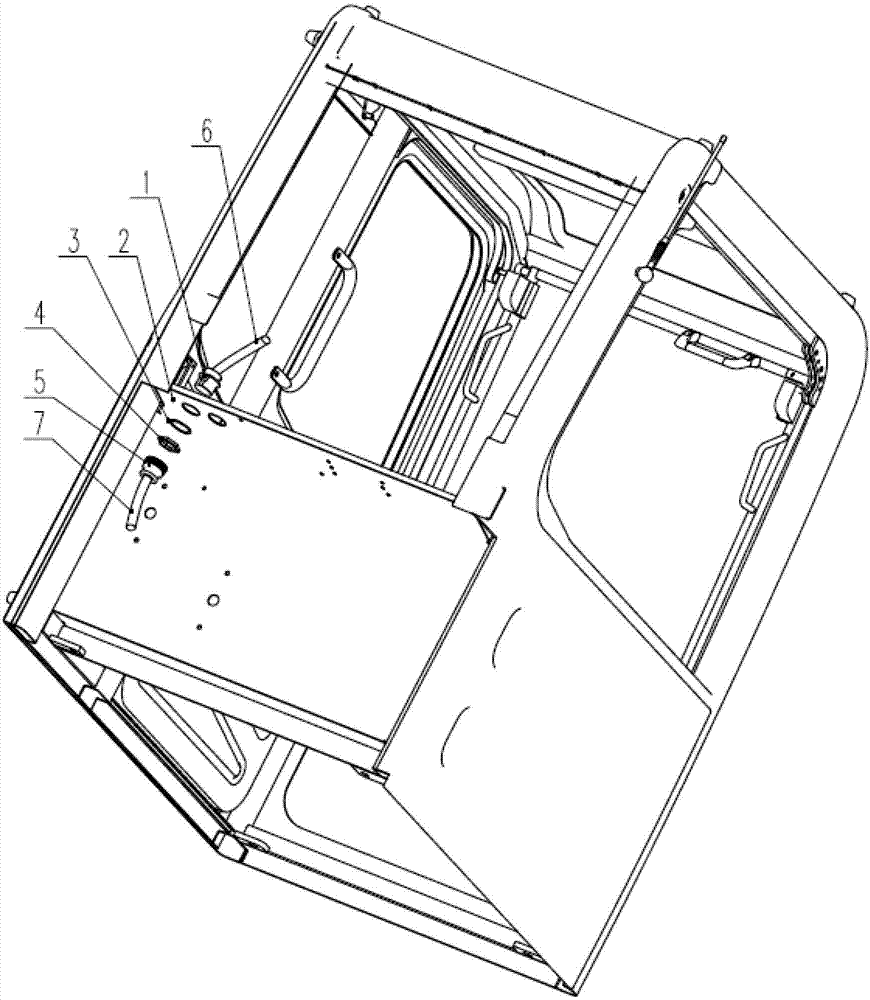

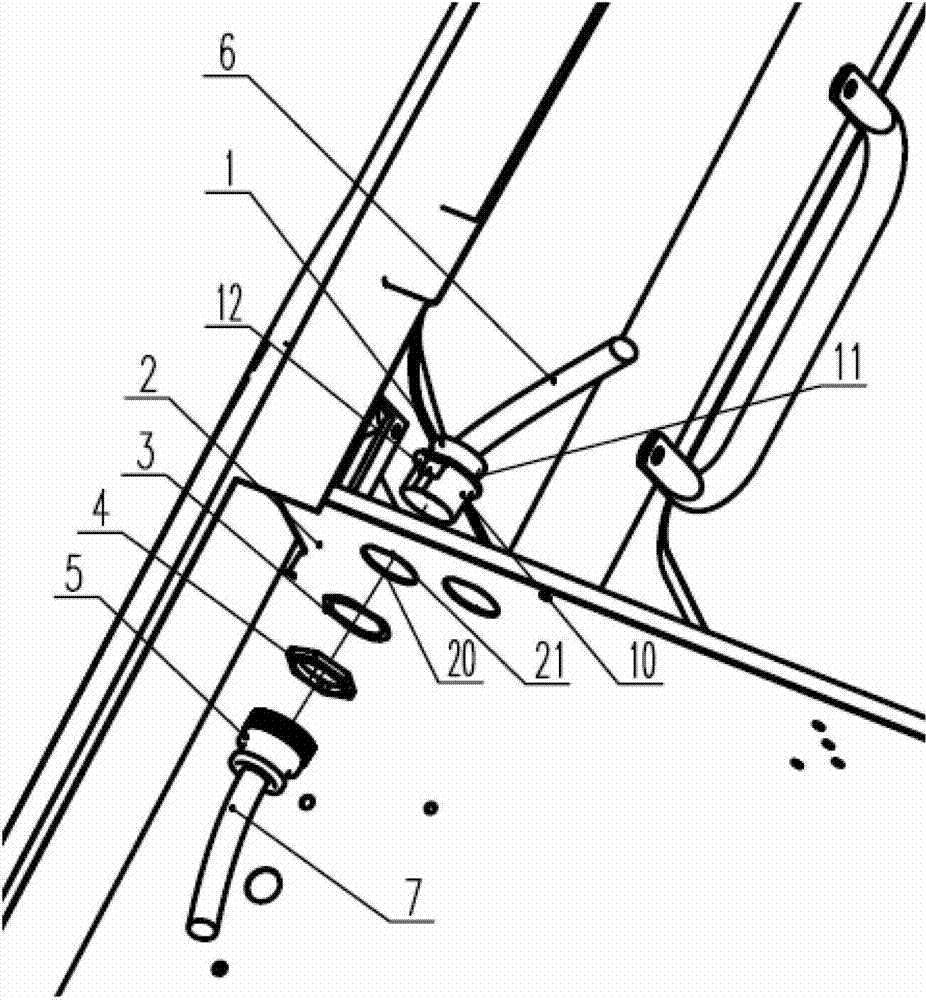

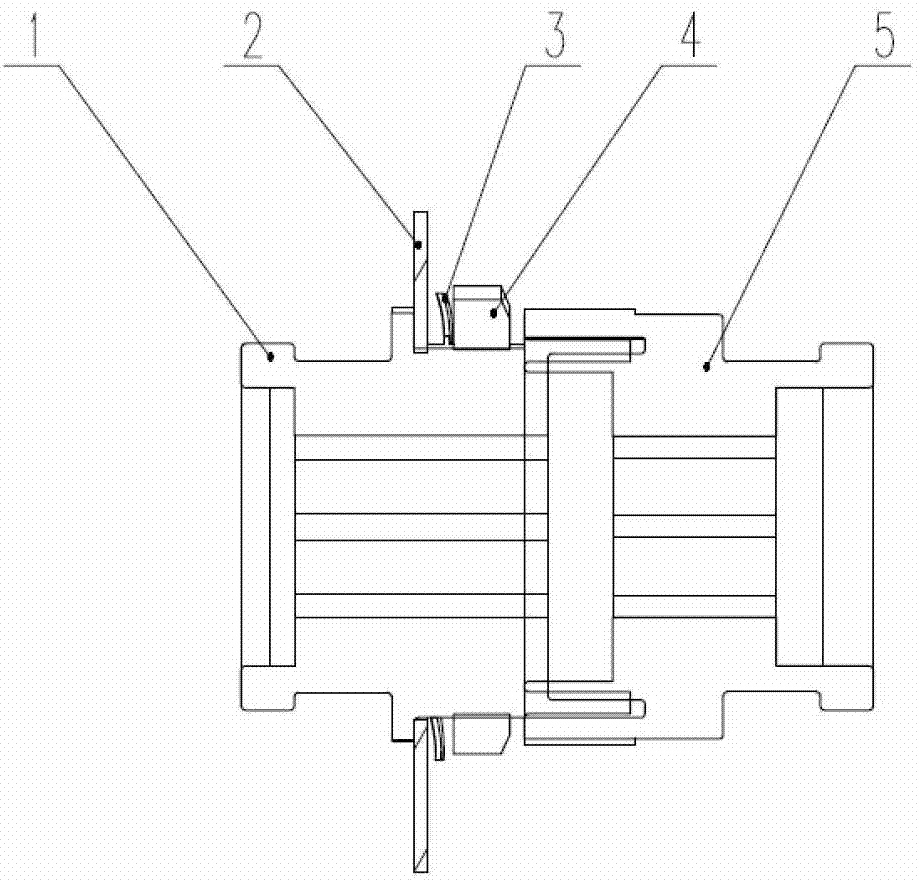

[0017] see figure 1 , figure 2 and image 3 , the first connector 1 and the second connector 5 can be inserted into each other, and there are anti-wrong insertion positioning grooves and anti-loosening devices between the first connector 1 and the second connector 5, the first connector 1 and the second connector The two connectors 5 can be respectively electrically connected to two independent wire harnesses which are divided into two sections from the same wire harness. Mounting holes are provided on the mechanical structure 2. The first connector 1 has a cylindrical surface 10, and one end of the cylindrical surface 10 has a positioning The boss 11, the cylindrical surface 10 is processed with a thread 13, the thread 13 is screwed with a spring washer 3 and a lock nut 4, the first connector 1 is inserted and installed in the mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com