Second-generation adjustable steel roll container support

An adjustable, coiled steel technology, applied in the sustainable packaging industry, packaging, external frames, etc., can solve the problems of reduced safety, inability to recycle, and high storage costs, so as to improve the efficiency of shipping and return, and save manpower and materials , The effect of improving storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

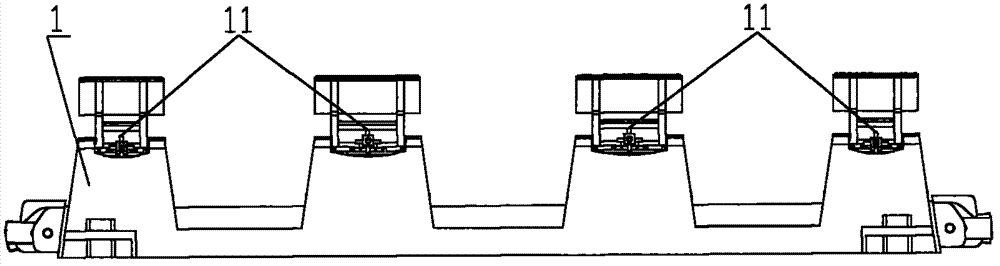

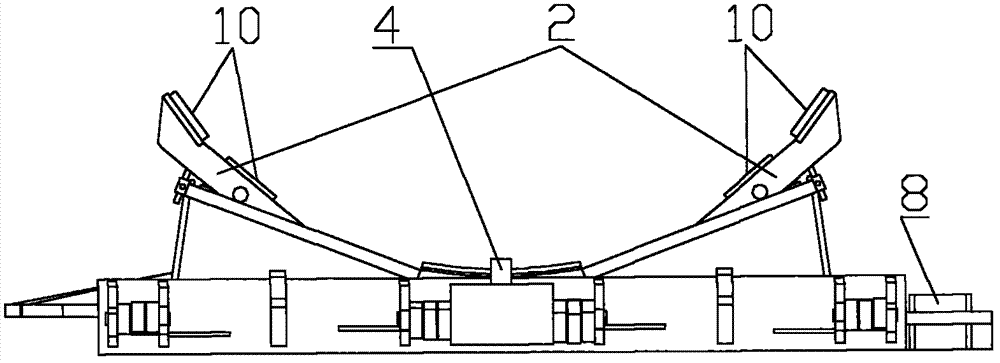

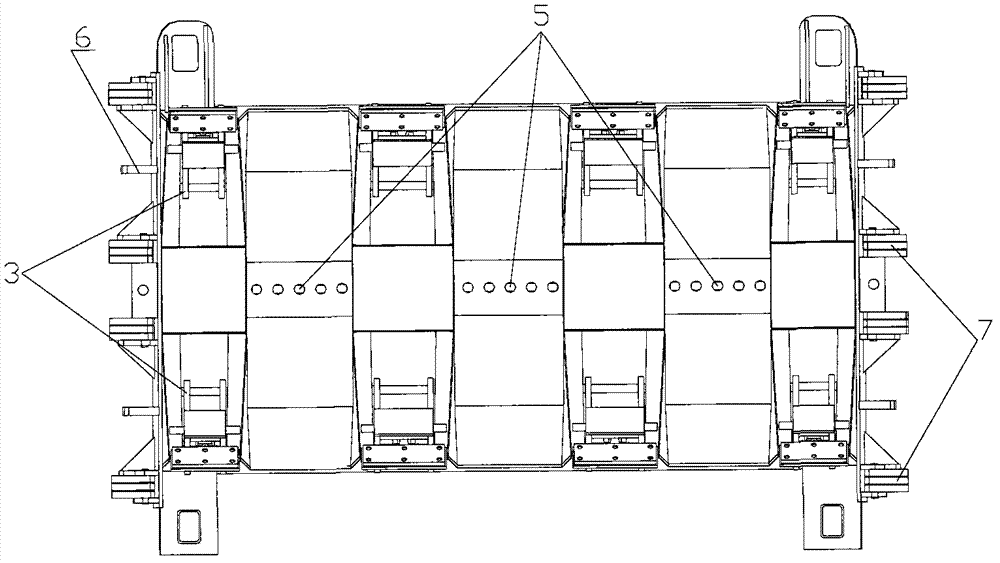

[0020] in the instance Figure 5 In the middle, after the large-diameter coil is placed on the coil bracket frame (1), the coil diameter adjustment slide plate (2) slides outward in the chute (3) until the coil diameter adjustment slide plate (2) is on the The anti-skid pad (10) is tightly attached to the coil steel, and the bolts on the sliding plate locking device (11) are tightened, so that the sliding plate locking device (11) firmly fixes the coil steel diameter adjusting plate (2), and finally tighten the anti-skid plate (11). To complete the loading, move the piston (4).

[0021] in the instance Image 6 After the medium and small diameter coils are placed on the coil bracket frame (1), adjust the coil diameter adjustment slide plate (2) and slide inward in the chute (3) until the coil diameter adjustment slide plate (2) is on the The anti-skid pad (10) is tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com