Hydrogen storage isotopic sc-cr-mn alloys with high activity and high resistance to hydrogen-induced disproportionation

A sc-cr-mn, high-activity technology, applied in various metal hydrides, etc., can solve the problems of induced disproportionation, hysteresis, and the decrease of released hydrogen, and achieve strong anti-poisoning ability, good dynamic performance, anti-powder good chemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the technical contents, characteristics and effects of the present invention, the detailed description is as follows below in conjunction with the accompanying drawings:

[0016] Synthesis of Sc-Cr-Mn alloy: use commercial metal elements Sc block and Cr, Mn flakes as starting materials, the element purity is not less than 99.9%, according to the nominal composition Sc (Cr 0.5 mn 0.5 ) 2 (The alloy composition is the atomic percentage, at.%) After batching, it is repeatedly smelted 4 times in a magnetron electric arc furnace protected by a high-purity Ar (99.999%) atmosphere (the alloy ingot should be turned over and remelted at a high temperature while it is hot, so as not to break), and made into an alloy ingot weighing about 30 grams.

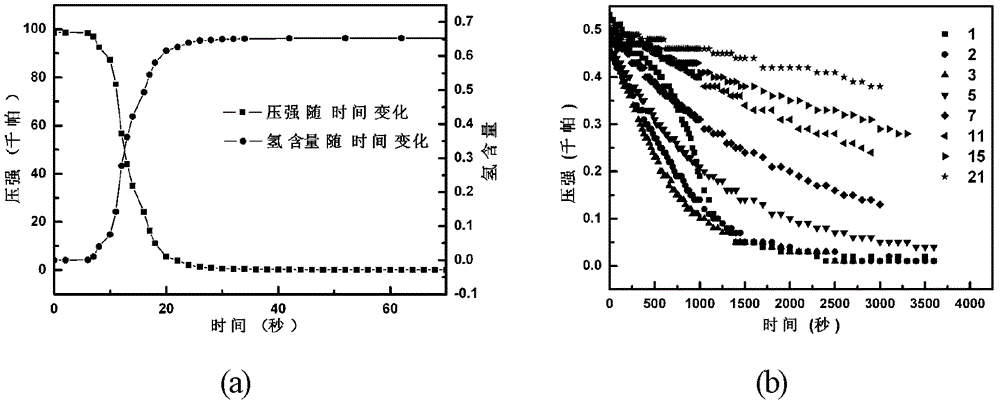

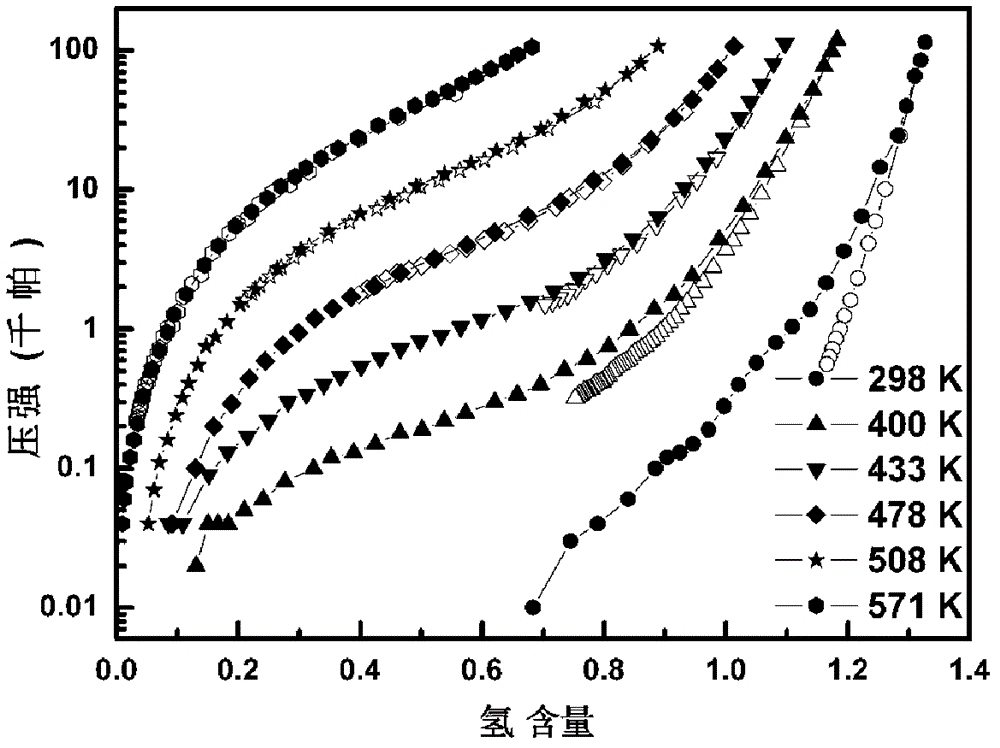

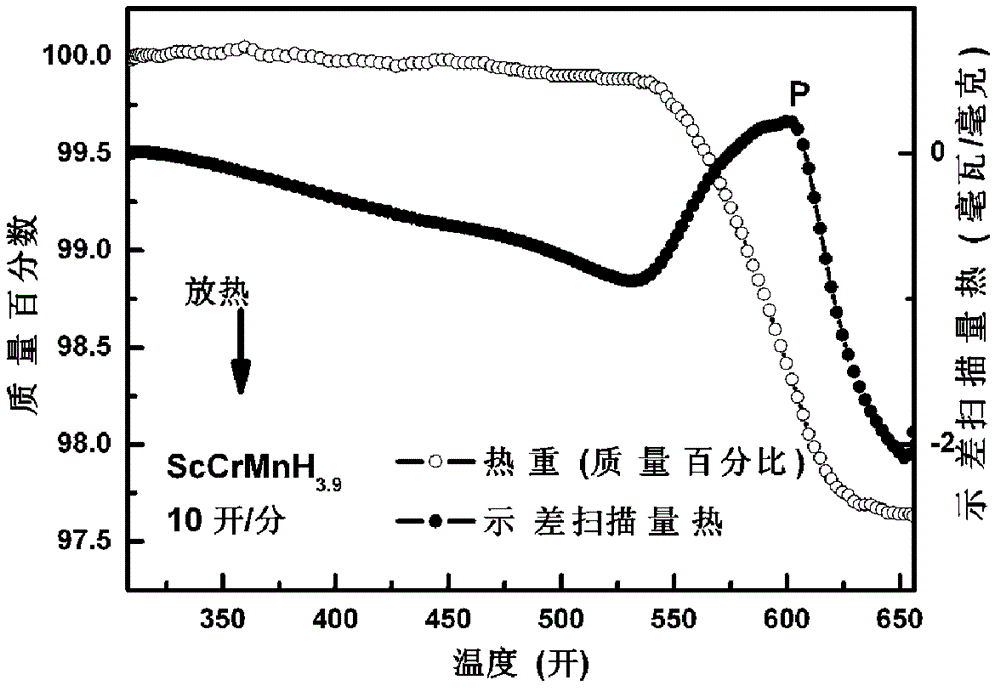

[0017] Break open the alloy ingot and take out a sample with a fresh surface of about 0.6 grams, put it in the sample chamber of the self-made hydrogen reactor, vacuumize the mechanical pump for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com