TJD mild steel damper

A mild steel damper and steel technology, applied in building components, shockproof, etc., can solve the problems of single energy consumption performance, small initial stiffness, etc., to reduce the amount of steel used, enhance the bending resistance of the support, and reduce the appearance of the support effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

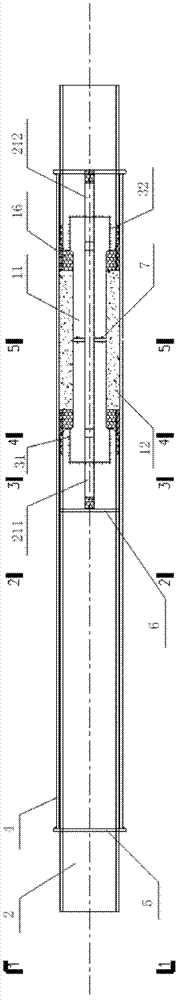

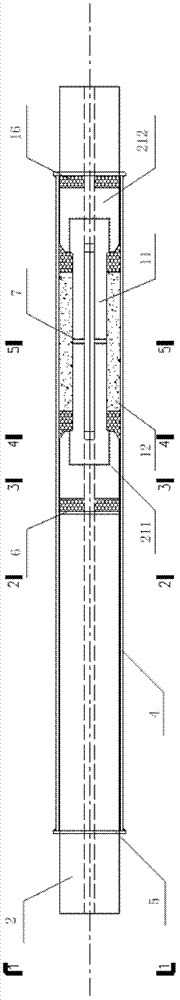

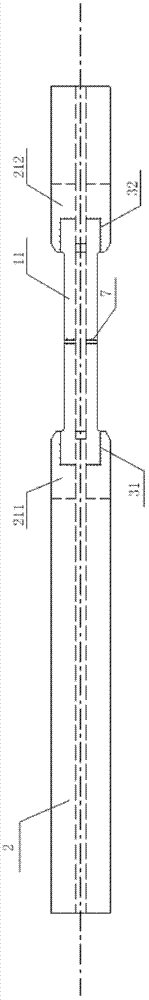

[0036] The invention provides a TJD mild steel damper, also known as the TJD mild steel damper, which uses high-strength steel as the load-bearing part, reduces the amount of steel used, and reduces the requirements for the appearance of the support; The waste of the core plate is eliminated; the arc transition is used to avoid the fracture of the core plate caused by the stress concentration; the way of extending the sleeve to a part of the bearing part enhances the bending resistance of the support and stabilizes the overall stability; avoids the on-site damper Segmented splicing realizes the integration of bearing parts and energy-consuming parts, and there are no splicing bolts and splicing welds, and the appearance is beautiful.

[0037] figure 1 A front view of the mild steel damper according to the first embodiment of the present invention is shown. Specifically, in this embodiment, the mild steel damper mainly includes an energy dissipation element 1 and a bearing ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com