Assembling method of triangular pyramid unit of honeycomb reticulated shell

A triangular cone and honeycomb-type technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as low engineering quality, large labor, material, and mechanical consumption, and insufficient fineness, so as to achieve convenient construction and assembly accuracy. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

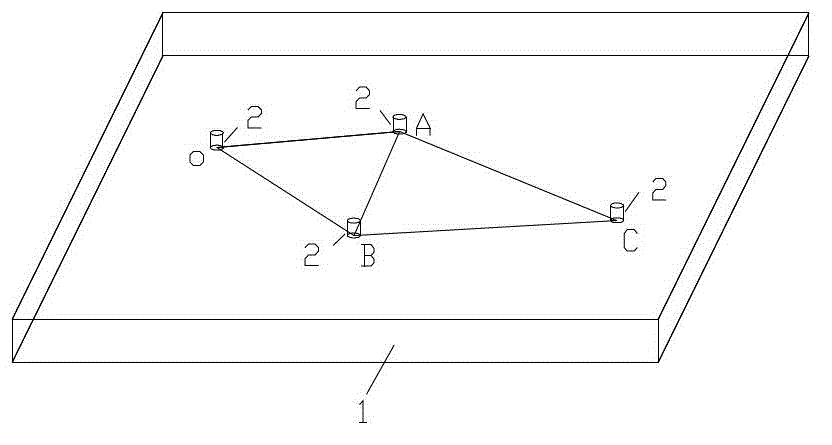

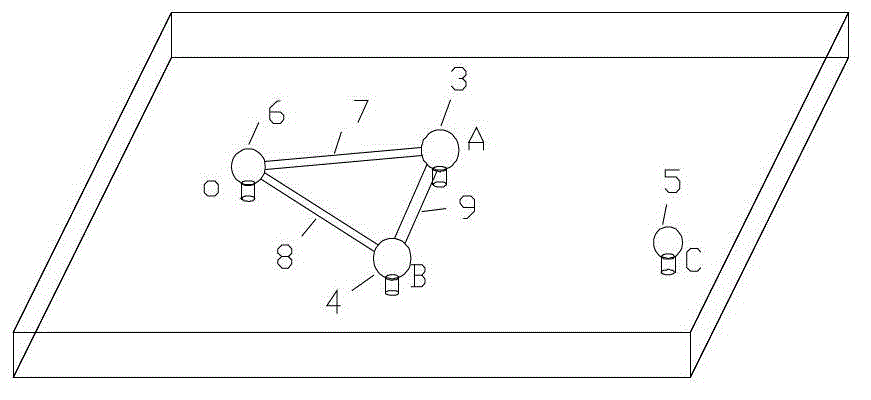

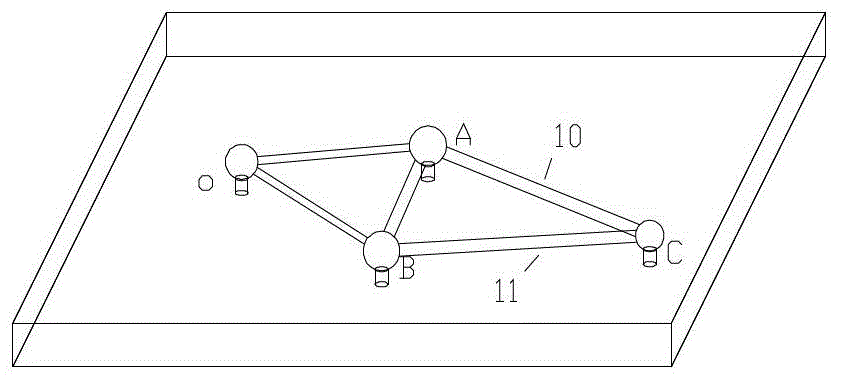

[0018] A method for assembling a triangular pyramid unit of a honeycomb reticulated shell, the specific steps are as follows:

[0019] 1. Prefabricate a stable and flat steel platform (1); according to the different radius of the ball in the triangular cone, prefabricate the ball tube support (2) of different heights. The purpose of this is to keep the center of the ball at the same height, that is, the triangle three points on a horizontal plane.

[0020] 2. According to the distance of each ball node obtained by the programming software, in the actual setting out on site, considering the shrinkage of the weld seam, add 3mm to the length as the setting out size. Release the lower string triangle on the steel platform (by the lower string ball A (3), the lower string ball B (4), the lower string ball C (5) and the lower string rods X1 (9), X2 (10), X3 (11)) and any Cone triangle (consisting of top string O (6), bottom string X1 (3), bottom string X2 (4), web F1 (7), web F2 (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com