Efficient combination type lifting device

A lifting device and combined lifting plate technology, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of single structure of lifting plate, corrosion of equipment cylinder, serious sticking of cylinder, etc. Achieve the effects of improving heat exchange efficiency, reducing design length and increasing effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

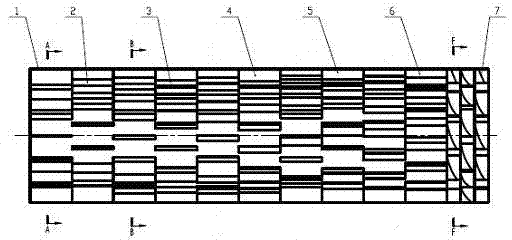

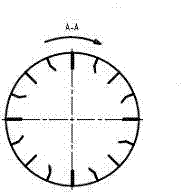

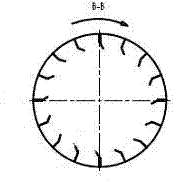

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The high-efficiency combined lifting device includes a cylinder body 1 and multi-stage combined lifting plates arranged sequentially on the inner wall of the cylinder body 1 along the traveling direction of the material in the cylinder body 1. Each level of combined lifting plates includes multiple columns in the form of The lifting plates are ring-shaped arranged on the inner wall of the cylinder body 1. The two adjacent rows of lifting plates are staggered in the radial direction, and the bending degree of the lifting plates in the combined lifting plates of the latter stage is higher than that of the previous stage. There is an increase.

[0022] The multi-stage combination lifting board includes the first-level combination lifting board 2, the second-level combination lifting board 3, the third-level combination lifting board 4, the fourth-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com