Ferry glass reinforced plastic boat lateral thrust leak tightness detector

A technology of sealing detection and FRP boats, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve problems such as difficult to be found, troublesome ship operation, water leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

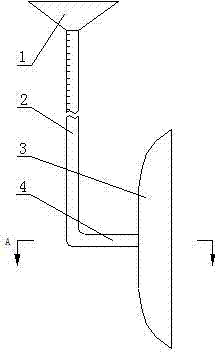

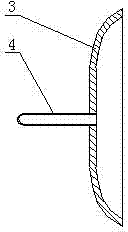

[0012] Such as figure 1 , figure 2 The side push seal detection device for FRP ships is provided with a detection cover 3 connected with a pressurized pipe 4, one side of the detection cover is provided with a pressurized water pipe 2, and the lower end of the pressurized water pipe 2 is connected to the pressurized The pipe 4 is connected, and the pressurized water pipe 2 and the pressurized pipe 4 can also be made integral. The upper end of the pressurized water pipe is provided with a water injection funnel 1, and the upper part of the pressurized water pipe is made of a transparent material and is provided with a scale line for easy observation. When in use, one end of the cylindrical flow channel that traverses the hull is sealed, usually using a cover to glue and seal it. This is the prior art and will not be described in detail; Bonding is also common here. Inject water and pressurize the cylindrical flow channel through the water injection funnel, stop the pressuri...

Embodiment 2

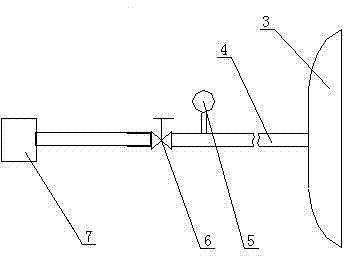

[0014] Such as image 3 The side push seal detection device of the FRP ship shown is provided with a detection cover 3, a pressure tube 4 is connected to the detection cover 3, a pressure pump 7 is connected to the other end of the pressure tube 4, and a pressure pump 7 is connected to the pressure tube 4. The pressure gauge 5 is provided with a detection valve 6 between the pressure gauge 5 and the booster pump 7 . When in use, seal one end of the cylindrical flow channel across the hull, and seal the other end of the cylindrical flow channel with the detection cover, open the detection valve, start the booster pump to pressurize the cylindrical flow channel, and the cylindrical flow channel After the pressure in the channel increases, close the detection valve, stop the booster pump, and observe the change of the pressure gauge for a period of time. If the pressure decreases, it means that the seal between the lateral thruster and the cabin is not tight. Find the leak point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com