Heat-producing fixing belt and image forming apparatus using the same

A technology of fixing belt and heat generating layer, which is applied to electric heating device, electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

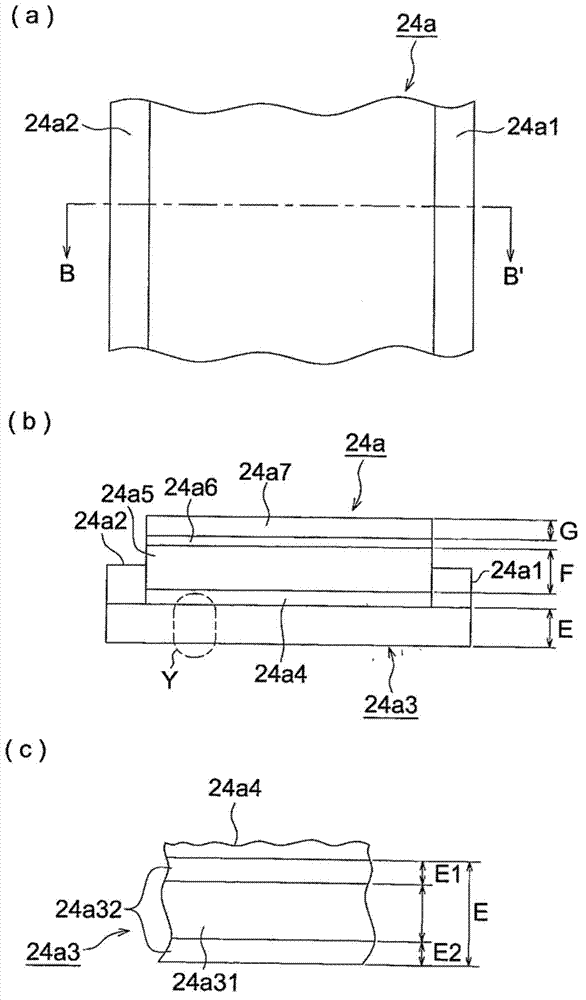

[0155] Created using the method shown below image 3 Heat-generating fixing belts of the structure shown, and designated as sample Nos. 101 to 109.

[0156] (Preparation for loop weaving)

[0157] Toray woven fabrics using carbon fibers shown in Table 1 were sewn together with carbon fibers to obtain endless woven fabrics.

[0158] [Table 1]

[0159]

[0160] 1-1 and 1-2 were produced by sewing cloth into a loop. 1-3~1-7 are made of carbon fiber weaving into cylindrical cloth. In Table 1, the thickness represents the equivalent image 3 The thickness of 24a31 in (c).

[0161] The thickness of carbon fiber shows the value measured based on JIS L0101-1978.

[0162] The fiber density of the woven fabric represents a value obtained by visually measuring the number of fibers in a range of 25 mm×25 mm. The thickness of the woven fabric represents a value obtained by measuring a cross-section with a reflection optical microscope.

[0163] (Wrapping of woven fabric with po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com