Recoil press

A press and pressure technology, applied in cranes, mechanical equipment, springs, etc., can solve the problems of increasing structural length, increasing weight, etc., and achieve the effects of short assembly size, light weight, and simple replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

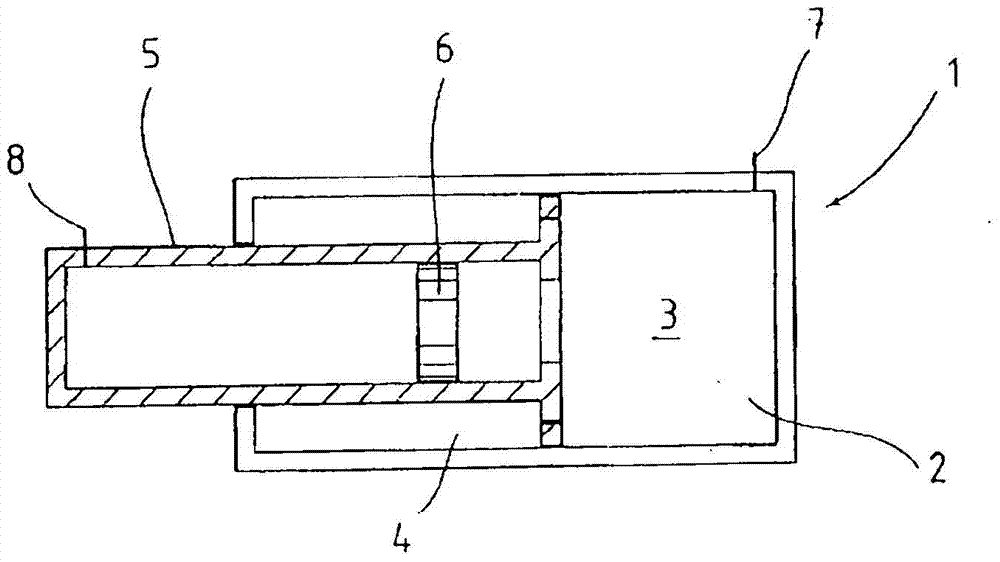

[0030] figure 1 The prior art, the recoil press 1 , is shown in a greatly simplified view. The recoil press 1 has a cylinder cavity 2 filled with oil. The oil is present both in the bottom cavity 3 and in the annular cavity 4 , which is penetrated by the piston rod 5 .

[0031] The piston rod 5 is configured as a gas accumulator. The isolation piston 6 inside the piston rod 5 will be present in this piston rod 5, especially N 2 , separated from the oil in other areas of the recoil press 1.

[0032] The cylinder cavity 2 can be filled with oil via the connection 7 on the bottom cavity 3 . On the piston rod 5 there is a connection 8 via which the interior of the piston rod 5 can be filled with gas.

[0033] This arrangement has a relatively high weight due to the oil used and the isolation piston required to separate the oil from the gas. This solution has the following disadvantages: the volume of gas must be slightly larger than the volume of oil displaced in the recipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com