Pump, in particular a high-pressure fuel pump

A high-pressure pump, fuel technology, applied in the direction of fuel injection pumps, fuel injection devices, liquid fuel engines, etc., can solve wear, contain particles, which may then also reach between the support element and the push rod body, can no longer guarantee Lubrication of supporting components and other issues to achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

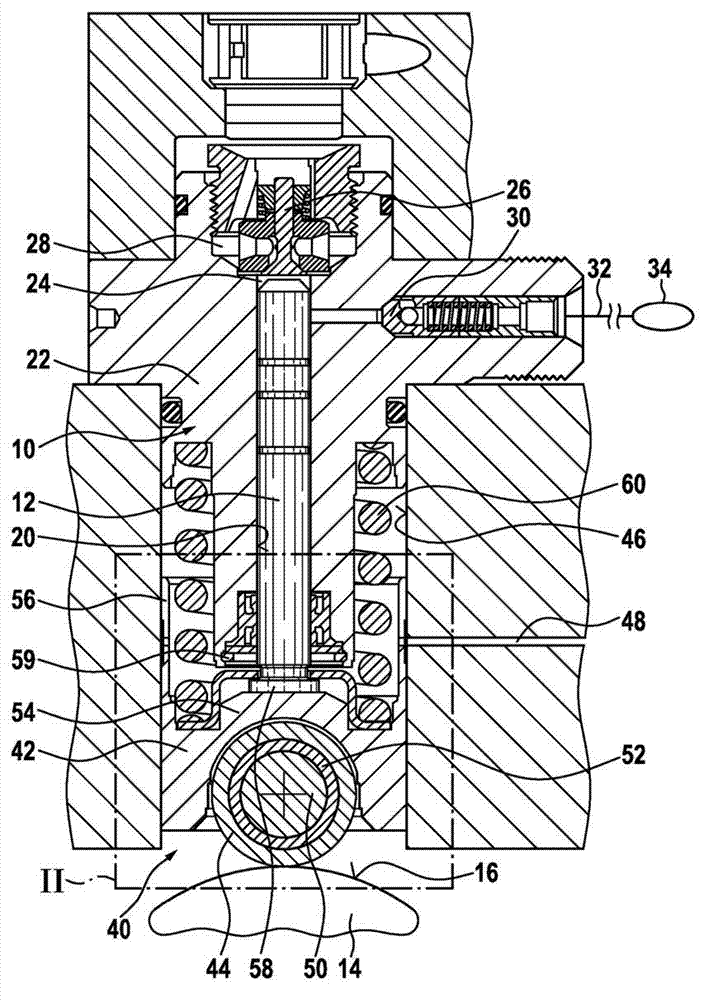

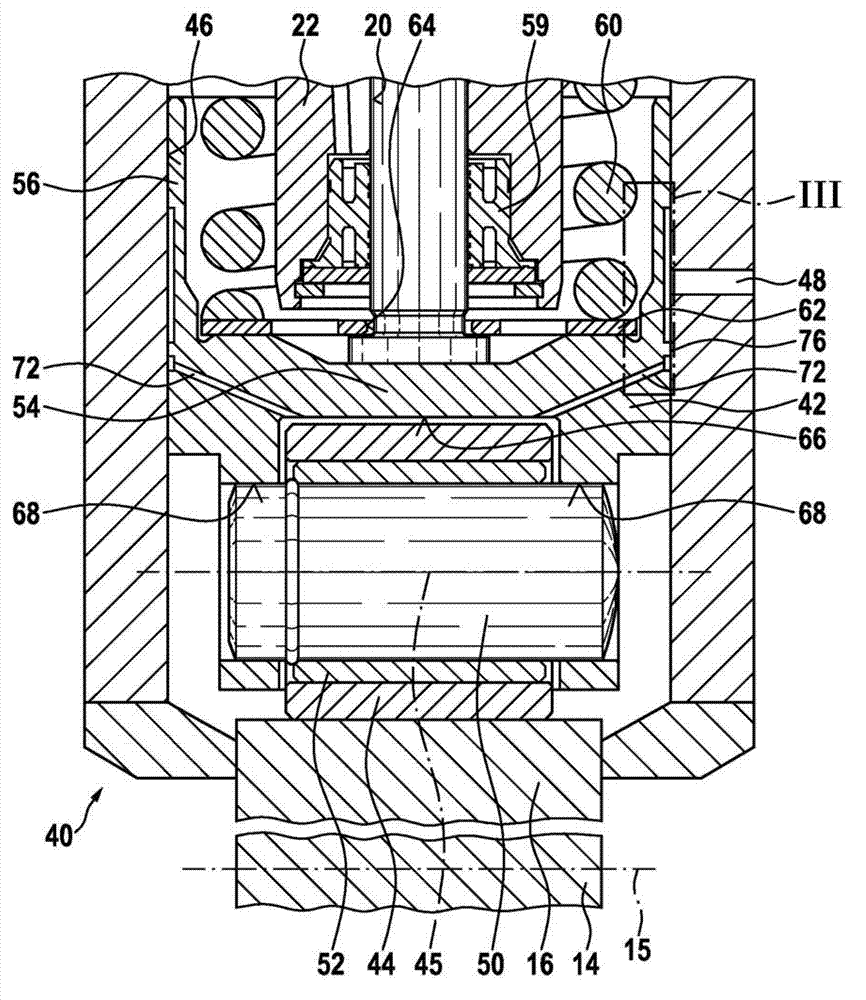

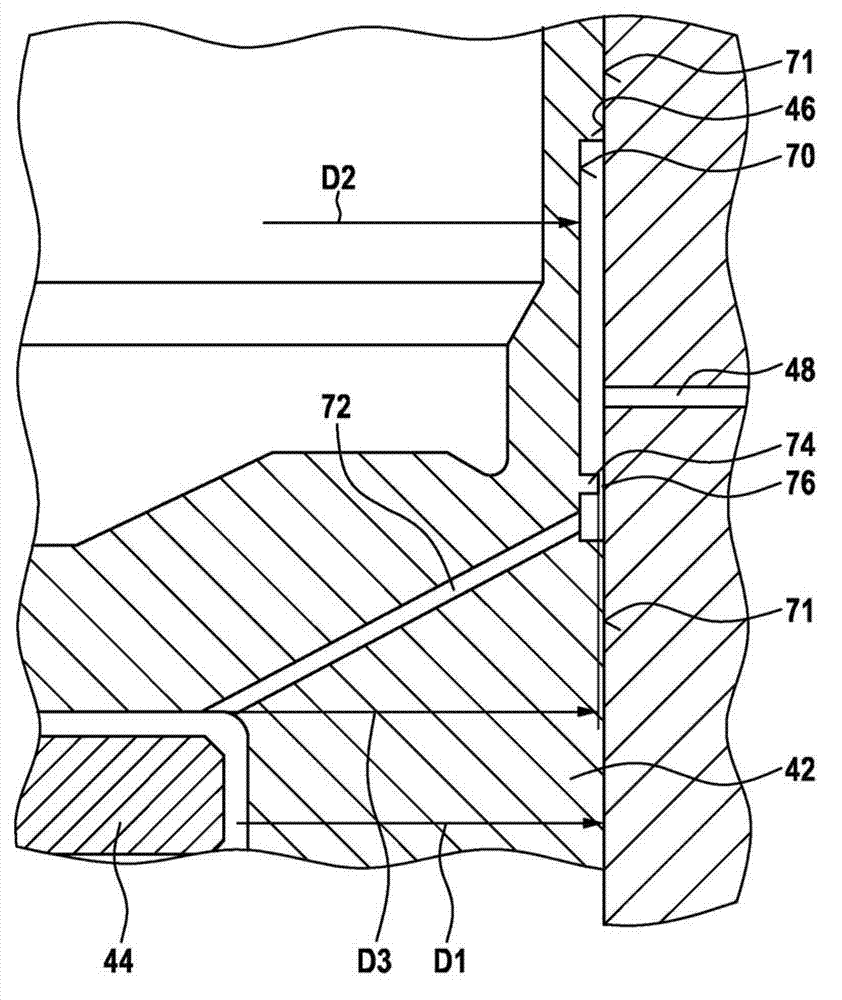

[0009] Figures 1 to 3 A pump is shown, in particular a high-pressure fuel pump for a fuel injection system for an internal combustion engine. The pump has at least one pump element 10 which in turn has a pump piston 12 which is driven at least indirectly by a drive shaft 14 to reciprocate linearly in a direction at least approximately radial to the axis of rotation 15 of the drive shaft 14 sports. The drive shaft 14 can be part of the pump, or alternatively it can also be provided that the pump has no drive shaft of its own and the drive shaft 14 is part of the internal combustion engine. The drive shaft 14 can here be, for example, a shaft of an internal combustion engine via which a gas exchange valve of the internal combustion engine is also actuated. The drive shaft 14 can have a cam 16 or an eccentric for driving the pump piston 12 .

[0010] The pump piston 12 is guided sealingly in a cylinder bore 20 of a housing part 22 of the pump. The pump piston 12 delimits a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com