Sensor

A sensor and through-hole technology, applied in the field of sensors, can solve problems such as poor sealing, welding (poor bonding, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

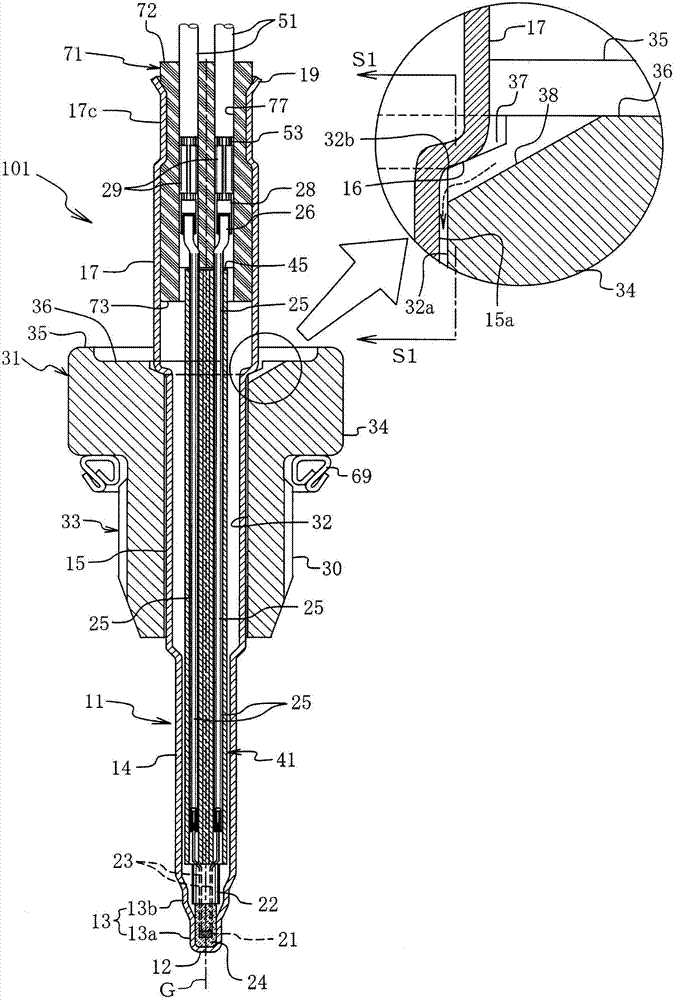

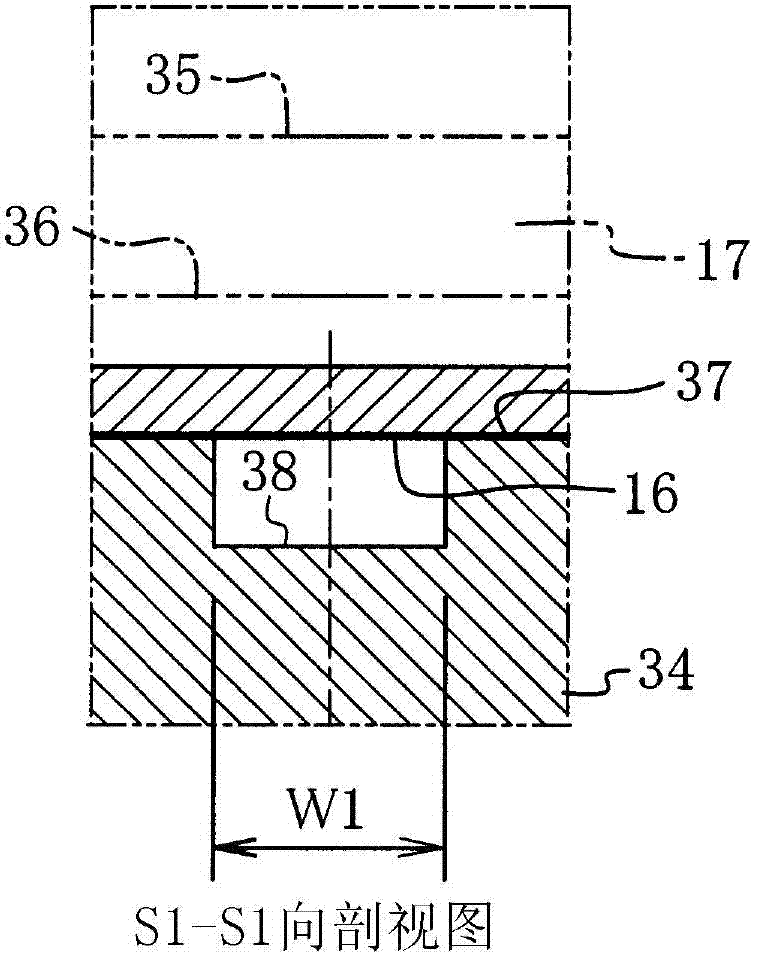

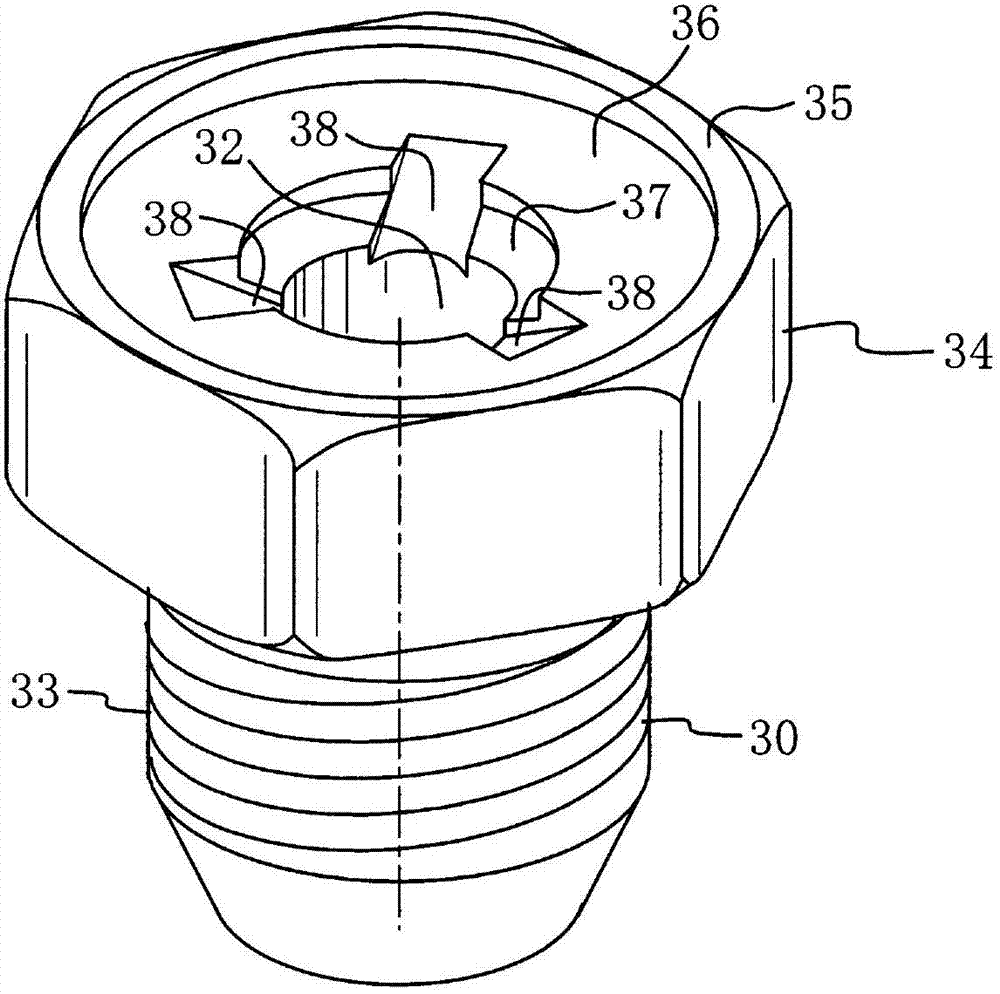

[0064] Regarding the embodiment (first embodiment) of the sensor embodying the present invention, based on Figure 1 to Figure 7 Describe in detail. figure 1 , reference numeral 101 is a sensor, which consists of a front end ( figure 1 The lower end) 12 of the tube 11 is made of metal (for example, made of SUS) closed, and the sensor element 21 arranged inside the front end 12 of the tube 11 or near the front end and the like. The tube 11 on which the element 21 is placed is inserted into a tube insertion hole 32 formed so as to surround the tube 11 at the center (inner side) of a ring-shaped attachment metal fitting 31 made of SUS, for example. The annular (cylindrical) circular hole is welded between the outer peripheral surface of the tube 11 and the inner peripheral surface 32 a of the tube insertion hole 32 with, for example, brazing (not shown). In addition, the ring-shaped mounting metal fitting 31 is formed such that an annular portion (cylindrical portion) 33 havi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com