DC-DC power conversion apparatus

A power conversion device and power transmission technology, applied in the direction of output power conversion device, conversion of DC power input to DC power output, conversion of AC power input to DC power output, etc., can solve the problem of increased volume and weight of inductors, DC/ The volume and weight of the DC power conversion device increase, and the effect of improving the power conversion efficiency is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

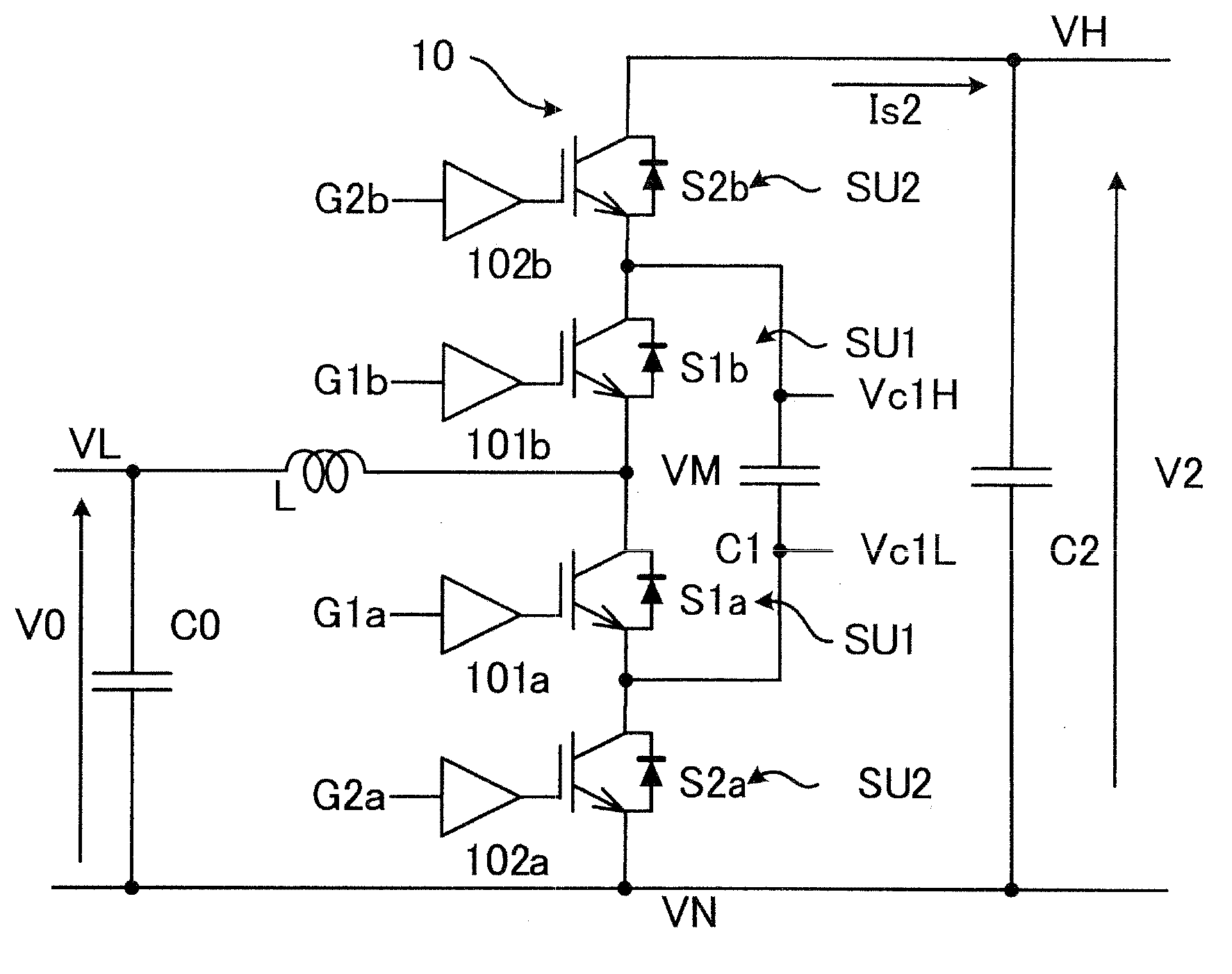

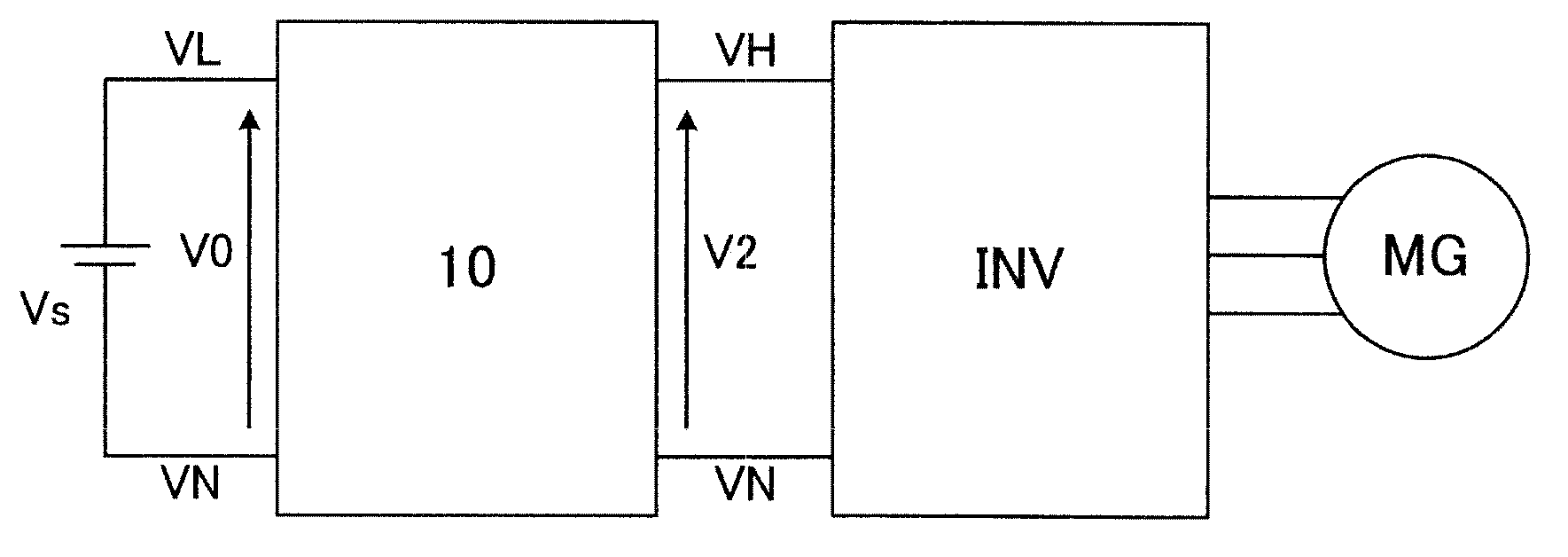

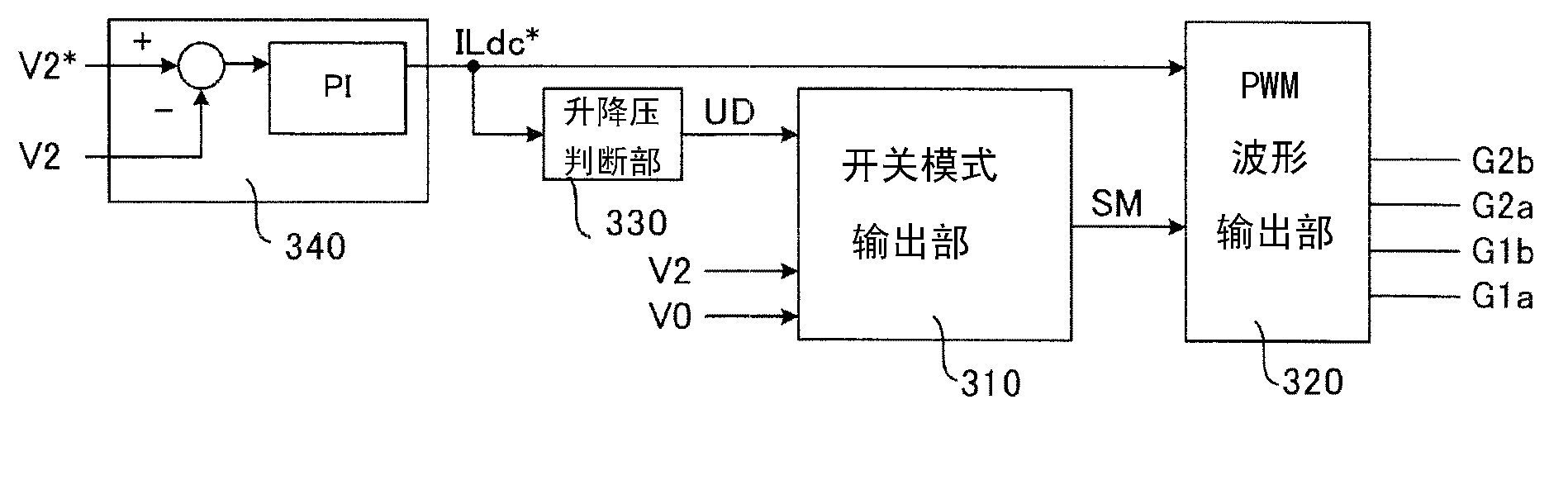

[0036] figure 1 It is a circuit diagram showing the main circuit configuration of the DC / DC power converter 10 according to Embodiment 1 of the present invention.

[0037] The DC / DC power conversion device 10 in Embodiment 1 is a bidirectional DC / DC power conversion device that has the following function: convert the DC voltage V0 input between the voltage terminal VL and the voltage terminal VN into a boosted DC voltage V2, the boost function output between the voltage terminal VH and the voltage terminal VN; and the DC voltage V2 input between the voltage terminal VH and the voltage terminal VN is converted into a step-down DC voltage V0, which is connected between the voltage terminal VL and the voltage Buck function of the output between terminals VN.

[0038] figure 1 Among them, the main circuit of the DC / DC power conversion device 10 includes: smoothing capacitors (smoothing condenser) C0, C2 for smoothing the input and output DC voltages V0, V2; smoothing capacitor C...

Embodiment approach 2

[0314] Figure 10 It is a circuit diagram showing the configuration of a main circuit of a DC / DC power converter according to Embodiment 2 of the present invention.

[0315] The DC / DC power conversion device 40 in Embodiment 2 is a bidirectional DC / DC power conversion device, which has the following function: convert the DC voltage V0 input between the voltage terminal VL and the voltage terminal VN into a boosted DC voltage Voltage V2, the boost function output between the voltage terminal VH and the voltage terminal VN2; and the DC voltage V2 input between the voltage terminal VH and the voltage terminal VN2 is converted into a step-down DC voltage V0, between the voltage terminal VL and the voltage terminal VN2 Step-down function for output between voltage terminals VN.

[0316] Such as Figure 10 As shown, the connection structure of the main circuit of the DC / DC power conversion device 40 according to Embodiment 2 is different from that of figure 1 The DC / DC power conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com