High-efficiency energy-saving reaction kettle of improved structure

A high-efficiency energy-saving, reactor technology, applied in chemical/physical/physicochemical stationary reactors, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of prolonging the production time of reactants and affecting product quality and accuracy , Reduce production efficiency and other issues, achieve the effect of reducing weight, saving energy and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

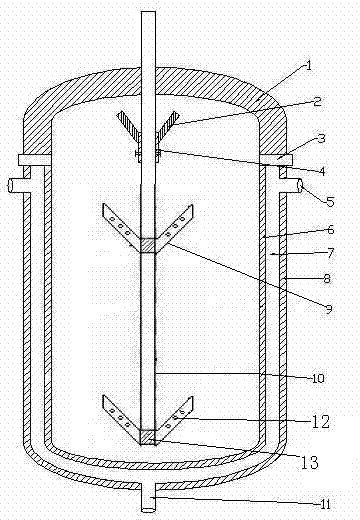

[0013] In order to further understand the high-efficiency energy-saving reactor with improved structure, combined with the attached figure 1 described as follows.

[0014] It mainly includes: an upper kettle body 1, a lower kettle body and a stirring paddle 9, and is characterized in that it also includes: a receiving device and a water circulation device, the upper kettle body 1 and the lower kettle body are fixed by a fixing device 3, and the stirring shaft 9 passes through The upper kettle body 1 is placed inside the lower kettle body, and the blade 10 is fixed on the stirring shaft 9 by two blades into a V shape. The blade 10 is provided with a through hole 11, and the diameter of the through hole 11 is 10-20 mm. The distance between the holes 11 is the same, a bearing 12 is provided between the blade 10 and the stirring shaft 9, and a sealing sleeve is provided outside the bearing 12; the blade is controlled by a control motor, and the receiving device is placed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com