Continuous casting device and method for large-dimension aluminum alloy plate blank

An aluminum alloy and large-size technology, which is applied in the field of aluminum alloy casting, can solve the problems of unstable liquid level, reduced ability to refine the structure, and limited range of ultrasonic field, and achieve the effect of improving macro segregation and refining the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

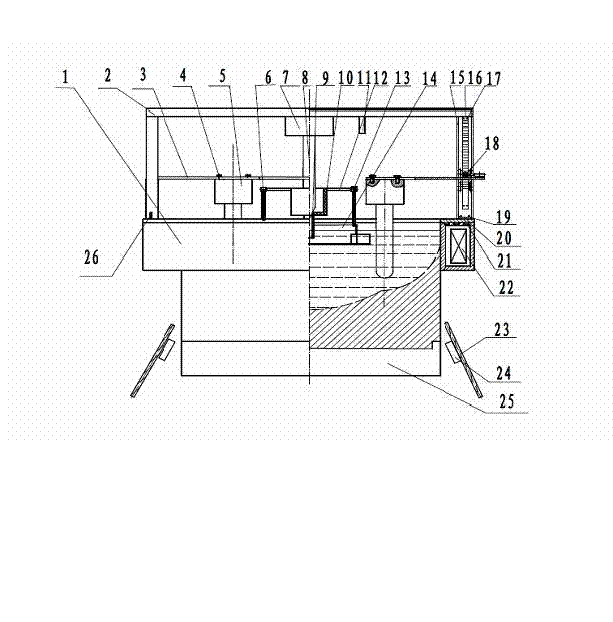

[0036] Combined magnetic field continuous casting of 7055 large slabs

[0037] Ingot size: 360mm (thickness) × 1000mm (width) × 4000mm length

[0038] The alloy composition of the aluminum alloy slab is calculated by mass percentage: Zn8.1%, Mg2.2%, Cu2.24%, Zr0.13%, and the rest is Al

[0039] Cast implementation:

[0040] (1) Turn on the cooling water, low-frequency power supply and ultrasonic device of the crystallizer, put the ultrasonic rod into the shunt bag, and put the equipment in the waiting state;

[0041](2) Put the shunt bag into the crystallizer, open the water supply valve of the crystallizer, and check whether the secondary cooling water is normal; start the low-frequency power supply, wind the coil for 100 turns, pass the frequency 15Hz, 100A current, and the magnetic field strength is 0.02T; turn on the ultrasonic power supply , the continuous ultrasonic frequency is 10KHz, the ultrasonic output power is 3KW, the diameter of the ultrasonic head used is 30mm...

Embodiment 2

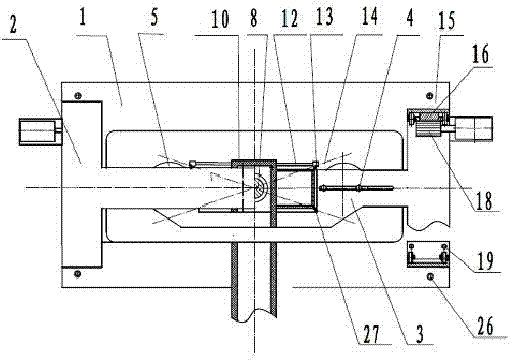

[0053] Combination Magnetic Field Continuous Casting of 7B50 Alloy Large Slab

[0054] Ingot size: 550mm (thickness) × 1650mm (width) × 500mm length

[0055] The alloy composition of the aluminum alloy slab is calculated by mass percentage: Zn6.63%, Mg2.44%, Cu2.20%, Zr0.13%, and the rest is Al

[0056] Cast implementation:

[0057] (1) Turn on the cooling water, low-frequency power supply and ultrasonic device of the crystallizer, put the ultrasonic rod into the shunt bag, and put the equipment in the waiting state;

[0058] (2) Put the shunt bag into the crystallizer, open the water supply valve of the crystallizer, and check whether the secondary cooling water is normal; start the low-frequency power supply, wind the coil for 300 turns, pass the frequency 30Hz, 300A current, and the magnetic field strength is 0.07 T; turn on the ultrasonic power supply , the continuous ultrasonic frequency is 20KHz, the ultrasonic output power is 4 KW, the diameter of the ultrasonic head ...

Embodiment 3

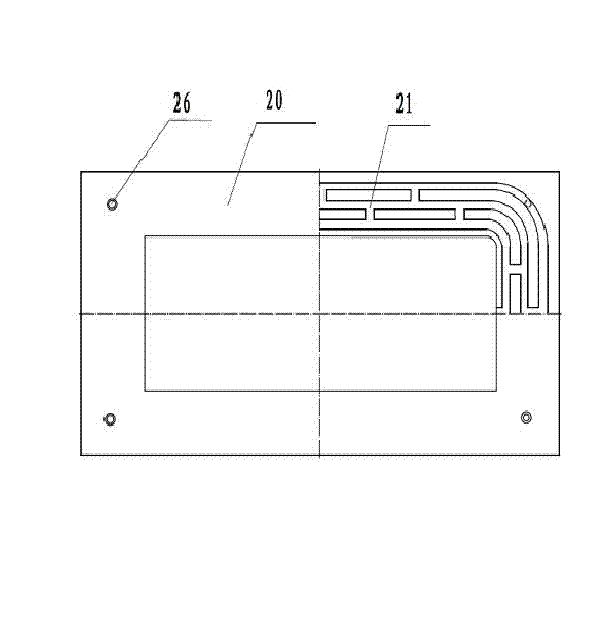

[0069] Combined magnetic field continuous casting of 7075 alloy large slab

[0070] Ingot size: 550mm (thickness) × 1650mm (width) × 500mm length

[0071] The alloy composition of the aluminum alloy slab is calculated by mass percentage: Zn5.62%, Mg2.55%, Cu1.50%, Zr0.20%, and the rest is Al

[0072] Cast implementation:

[0073] (1) Turn on the cooling water, low-frequency power supply and ultrasonic device of the crystallizer, put the ultrasonic rod into the shunt bag, and put the equipment in the waiting state;

[0074] (2) Put the shunt bag into the crystallizer, open the water supply valve of the crystallizer, and check whether the secondary cooling water is normal; start the low-frequency power supply, wind the coil for 500 turns, pass the frequency 50Hz, 500A current, and the magnetic field strength is 0.1 T; turn on the ultrasonic power supply , the continuous ultrasonic frequency is 30KHz, the ultrasonic output power is 5 KW, the diameter of the ultrasonic head used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com