A forging method for controlling the grain size of a super-large cross-section axial austenitic pipe

A technology of pipe control and section axis, applied in the field of metal forging, can solve the problems of difficulty in meeting the grain size requirements of forgings, increase the difficulty of forging and increase the smelting defects of steel ingots, etc., so as to improve macrosegregation, reduce product cost, and improve material quality The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] see Figure 1-7 , a forging method for controlling the grain size of a super-large cross-section axial austenite pipe, the forging method comprises the following steps:

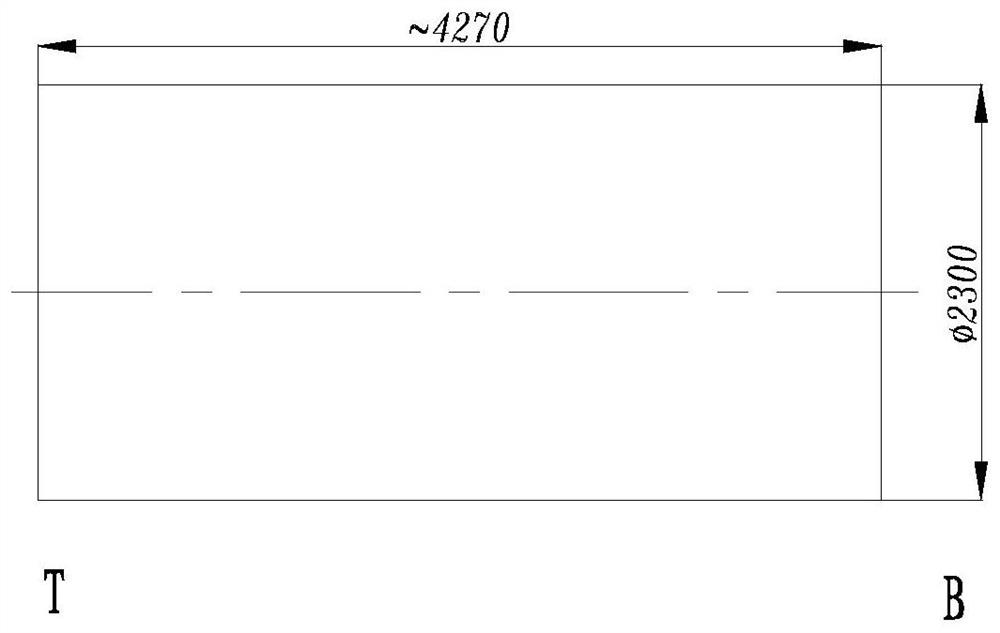

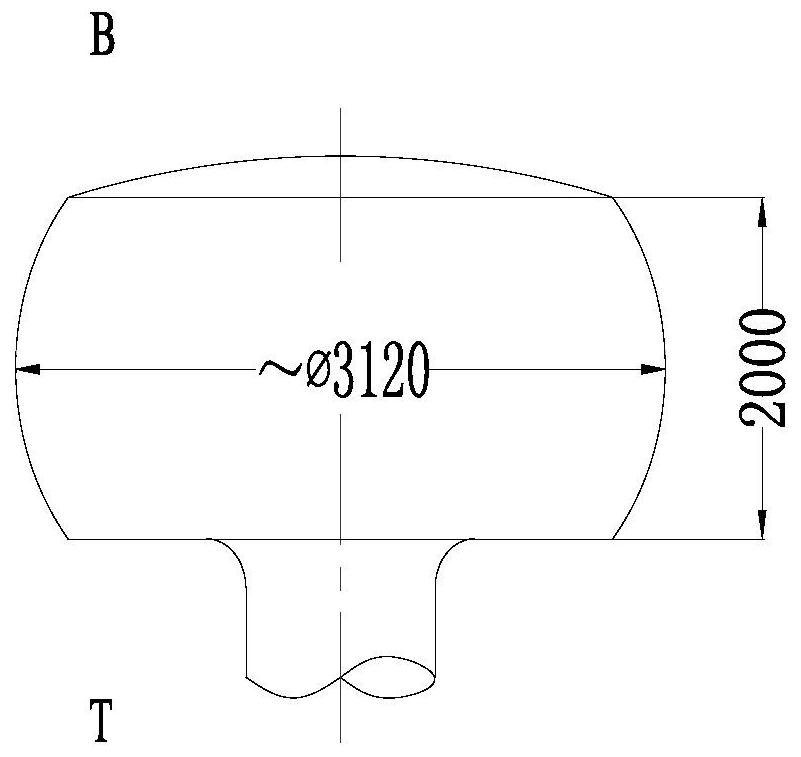

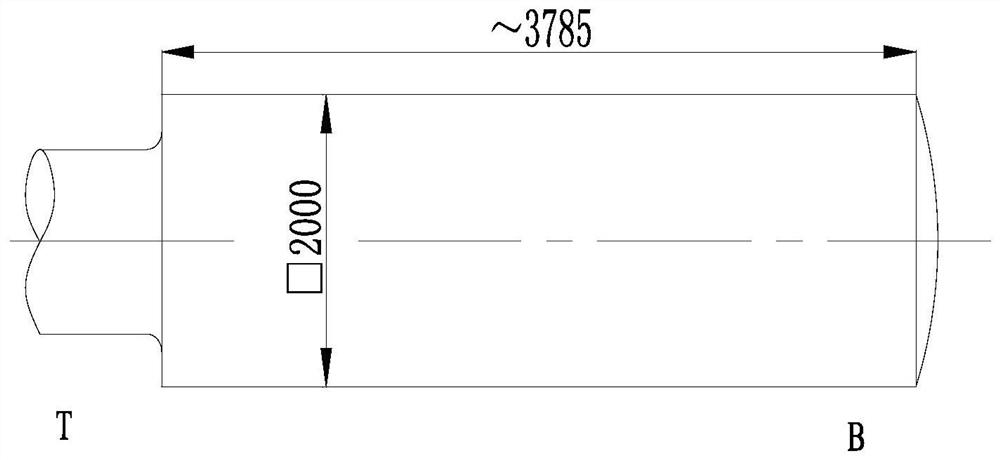

[0039] Step 1: Press the clamp + pre-pull, heat the stainless steel ingot to 1220℃~1270℃, keep the temperature for 37±5h, heat the forging billet into the furnace to 1220℃~1270℃ and keep it for a period of time before forging. The deformation amount of the single fire changes, and the surface of the steel ingot is lightly pressed three times. The single-sided reduction of the pressing clamp handle + the pre-drawn long forging billet A is 50-100 mm to make the forging billet A, and the columnar crystals on the surface of the steel ingot are broken to promote The surface grains undergo dynamic recrystallization, which improves the surface plasticity and reduces the cracking tendency; the dimensions of the electroslag ingot used in the hot section B of the main pipeline involved in the present invention a...

Embodiment 2

[0048] The other contents of this embodiment are the same as those of the first embodiment, the difference is that: in step 8, the straight sections at both ends of the middle nozzle are drawn in steps, and the nozzle sections are flattened by flat squares at the completion of the fire. forming.

[0049] The invention firstly reduces the component segregation of large-sized steel ingots by thermally insulating the steel ingots at a high temperature for a long time. Controlled forging technology is adopted, the temperature and time of forging holding are strictly controlled, and the coarse grains inside the steel ingot are quickly refined and the internal defects of the large steel ingot are welded by the combination of overall upsetting and wide anvil pressure. At the same time, controlling the single-fire deformation rate and the furnace heat preservation conditions to balance the forging deformation and dynamic recrystallization process is conducive to maintaining the fine-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com