Grain refining method based on grain refining device for semi-continuous casting of aluminum alloy

A grain-refining, semi-continuous technology used in metallurgy to solve problems such as cracking, ingot core and edges unable to solidify at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

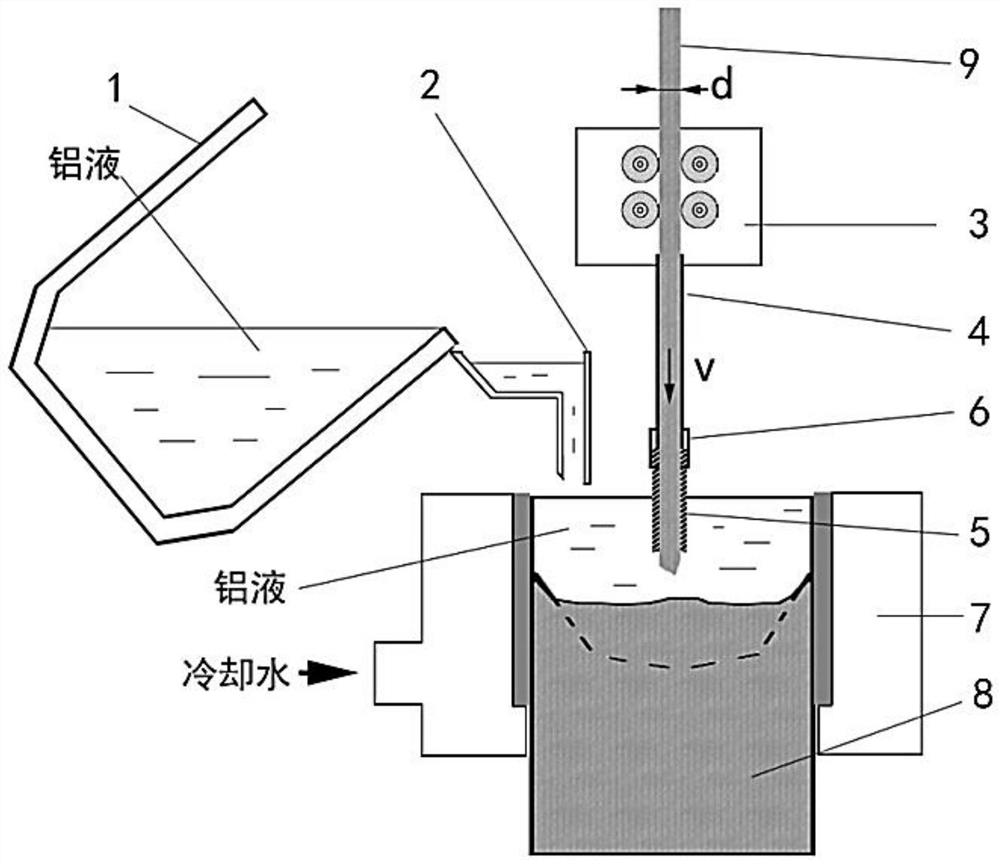

[0012] Such as figure 1 As shown, the grain refining device of the aluminum alloy semi-continuous ingot involved in the present embodiment includes: a push mechanism 3 facing the top of the crystallizer 7, the bottom of the push mechanism 3 is provided with a stainless steel sleeve 4 and The output device of the ceramic sleeve 5, the cooling mandrel 9 is located inside the output device.

[0013] The exterior of the crystallizer 7 is preferably provided with a water cooling mechanism.

[0014] This embodiment adopts the above-mentioned device, the casting material used is Al-4%Cu alloy, the temperature of the molten aluminum in the crucible is controlled to 700°C, the crystallizer (the diameter of the round ingot is 300mm) is passed through cooling water, and continuous or semi-continuous casting The process begins.

[0015] When the casting process reaches a stable state, the cooling mandrel with a diameter of 30mm is submerged into the center of the molten aluminum in the ...

Embodiment 2

[0018] Same as Example 1, the casting material used in this example is 7055 alloy, the temperature of molten aluminum in the crucible is controlled to be 730°C, the crystallizer (the diameter of the round ingot is 300mm) passes cooling water, and the continuous or semi-continuous casting process starts . When the casting process reaches a steady state, the cooling mandrel with a diameter of 35 mm is submerged into the center of the molten aluminum in the crystallizer through the ceramic sleeve to a depth of 180 mm, and the composition of the cooling mandrel is consistent with that of the molten aluminum. After 5 minutes, the cooling mandrel is pushed down at a speed of 25mm / min by the pushing mechanism, and the casting process and the new liquid-solid interface are kept dynamic and stable until the casting process ends.

[0019] The macro-component segregation of the edge and center of the obtained ingot is less than 5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com