Plate shearing machine with multiple shearing speeds

A technology for shearing machines and braking motors, applied in shearing equipment, shearing devices, metal processing equipment, etc., can solve problems such as difficult maintenance, easy oil leakage of hydraulic shearing machines, single shearing speed of shearing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

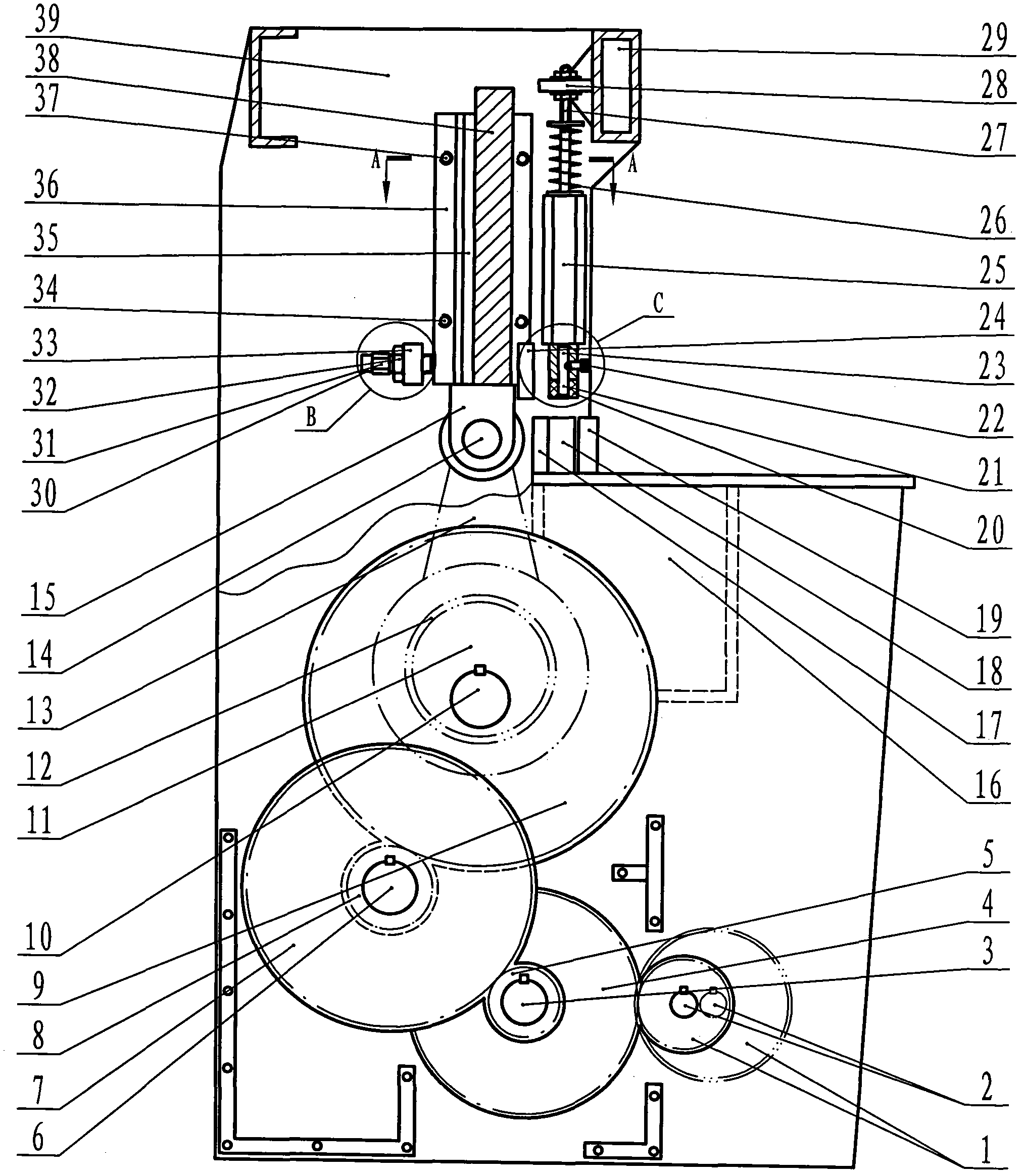

[0024] Example: in figure 1 Among them, the primary small gear (1) on the brake motor (2) drives the primary large gear (4) through the secondary small gear (5) on the primary shaft (3) to drive the secondary large gear (7) The third-stage pinion (8) on the second-stage shaft (6) drives the third-stage large gear (9) to drive the main shaft (10) to rotate the eccentric wheel (11) and the composite sleeve (12) to slide circularly, and there is a chain outside the composite sleeve Bar (13) pulls upper knife rest ear (15) by bearing pin (14) and makes upper blade (24) on the upper knife rest (38) move up and down and lower blade (17) on the lower knife rest (16) realizes cutting. cut function.

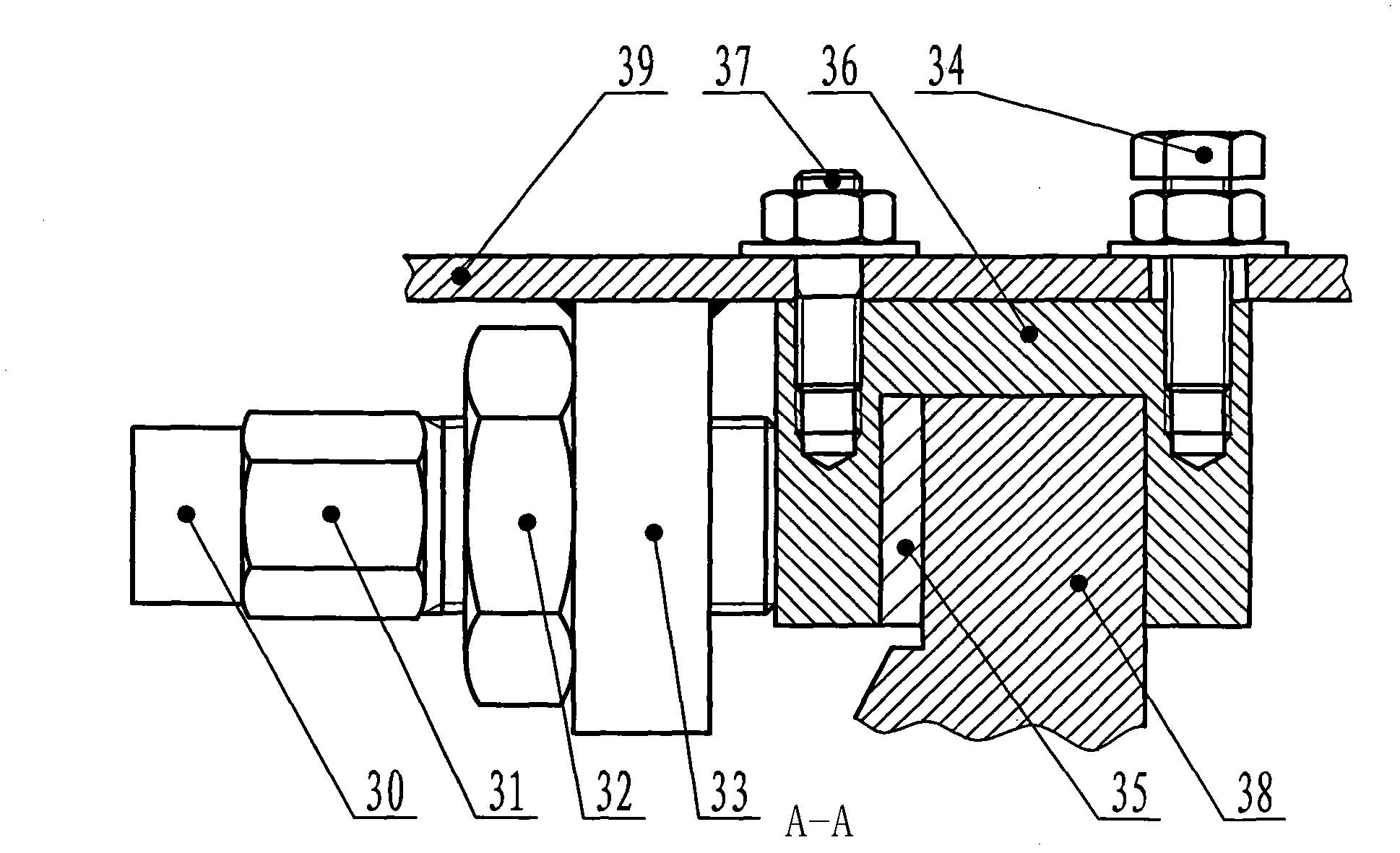

[0025] exist figure 2 Among them, the centering bolt (37) is the centering and fastening part of the sliding arm seat (36) circle; the locking bolt (34) is the locking part of the sliding arm seat (36).

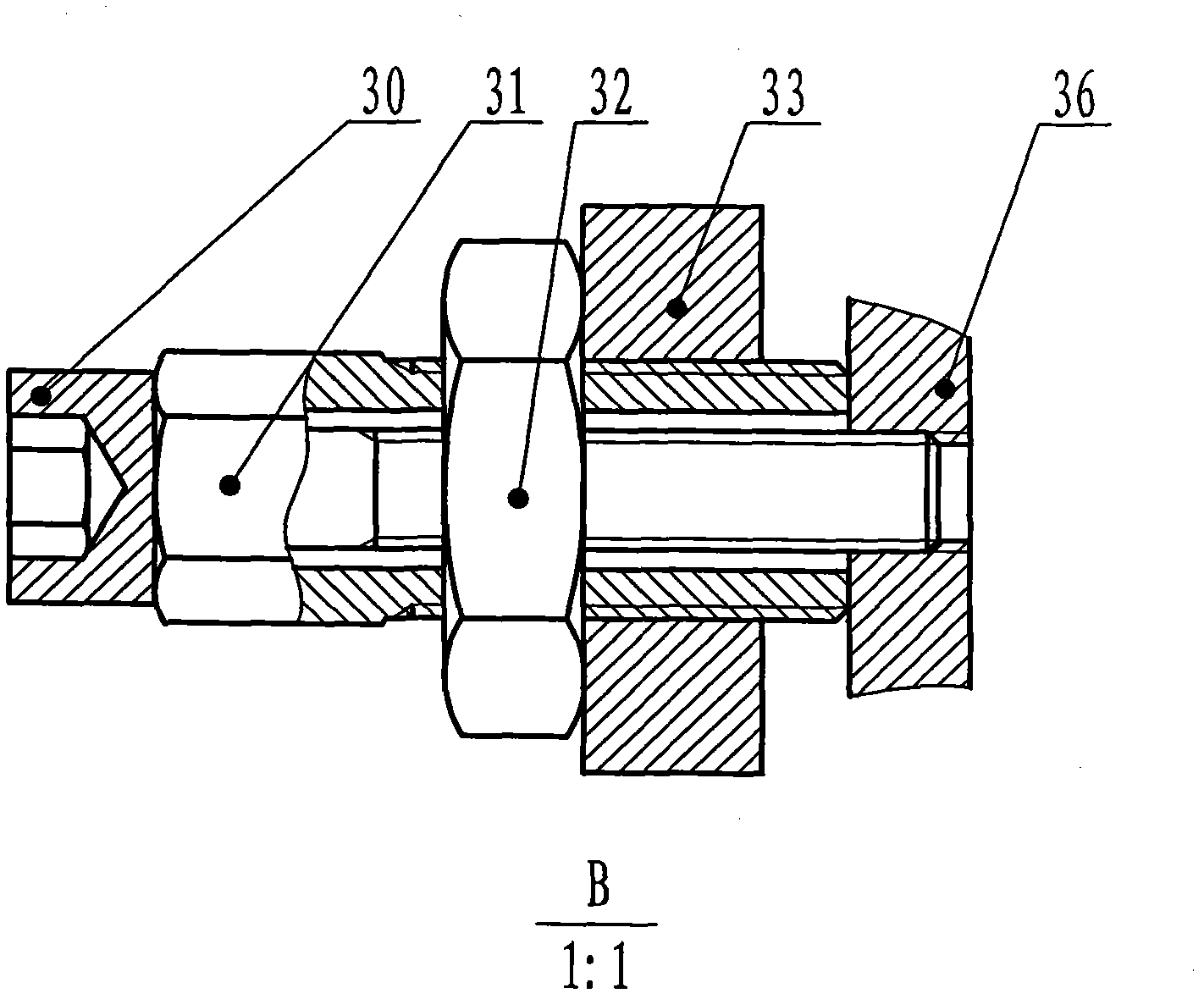

[0026] exist image 3 Among them, the bolt (30) can be tightened back to the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com