Multi-shaft door frame forming device

A molding equipment and door frame technology, applied in sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of many operators, loading and unloading errors, and low processing accuracy of molding products, and improve the processing safety factor , the use of less labor, the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

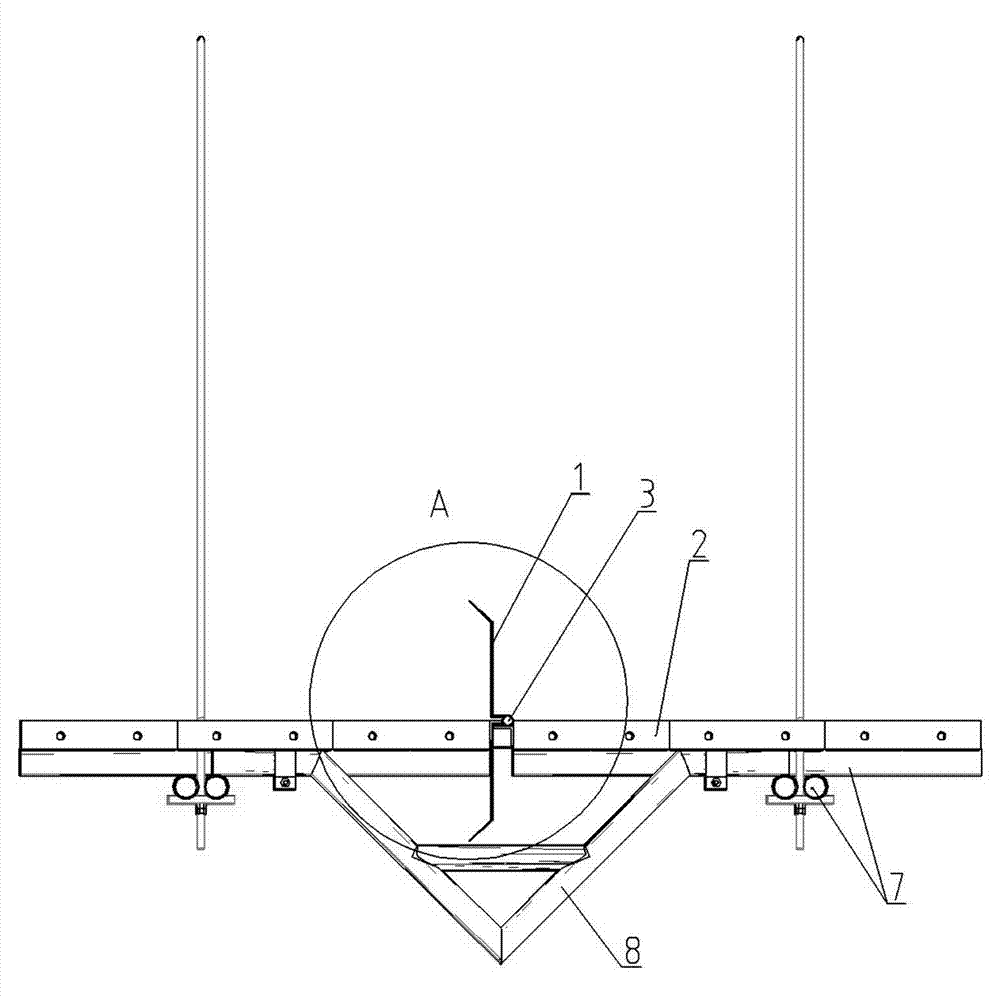

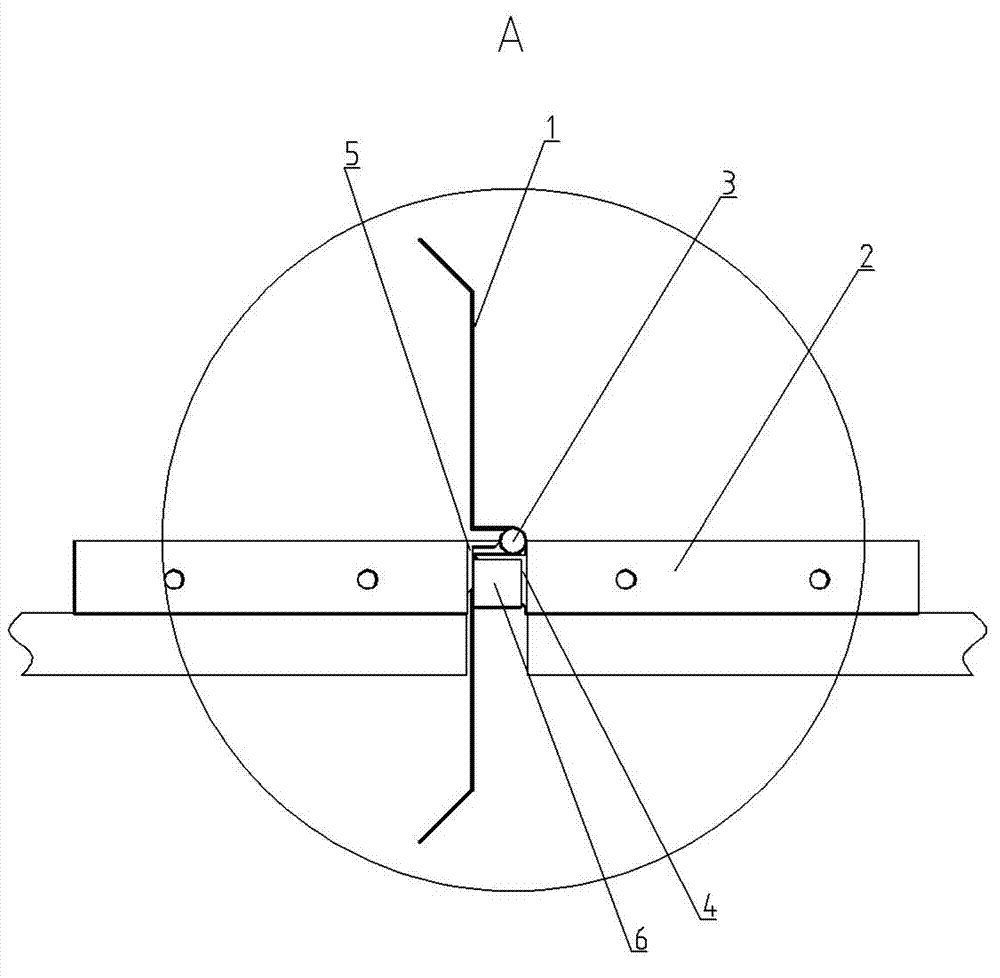

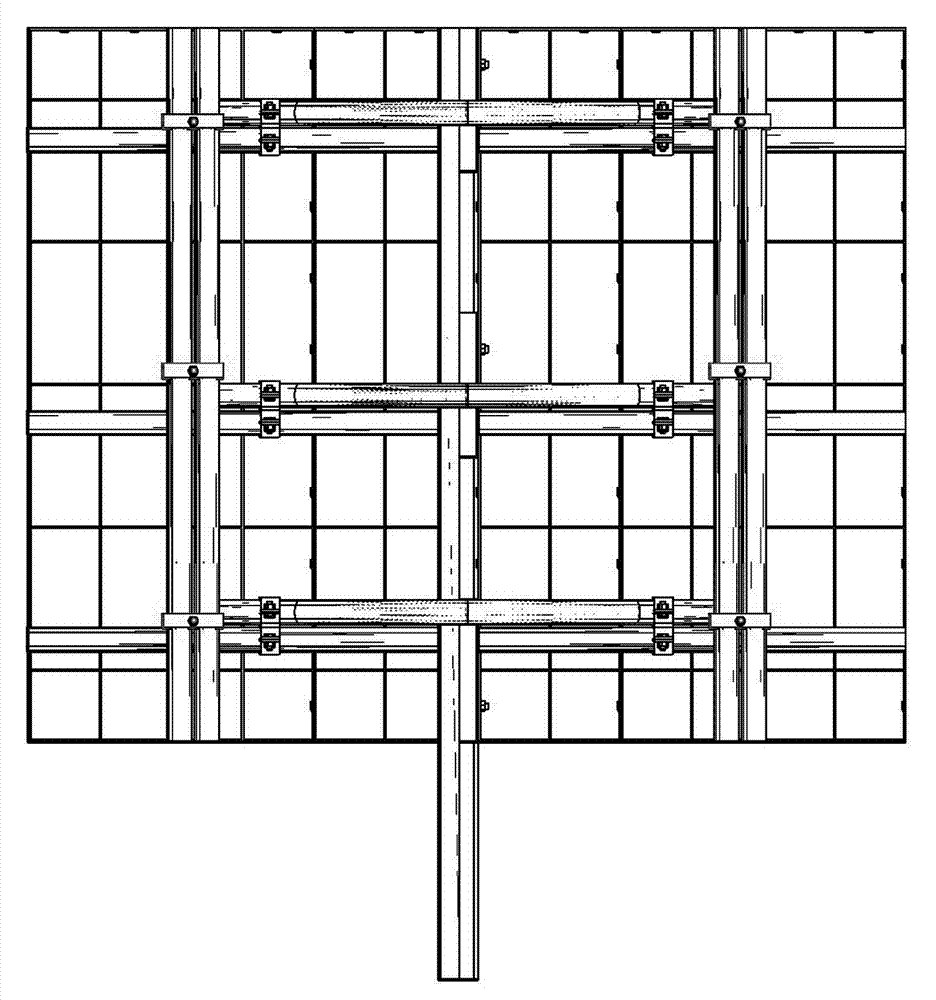

[0030] like figure 1 , 2 Among them, a multi-axis door frame forming equipment includes a frame 10, and the frame 10 is provided with a plurality of saw blades connected to the motor. A plurality of saw blades are arranged along the feed channel.

[0031] In an optimized solution, the motor is slidably connected to a base with a horizontal guide rail, and the base with a horizontal guide rail is slidably connected to the frame 10 through a vertical guide rail;

[0032] In another optional solution, or the motor is slidably connected to the base with vertical guide rails, and the base with vertical guide rails is slidably connected to the frame 10 through horizontal guide rails. This structure is more conducive to automatic control adjustment.

[0033] Other optional solutions are to replace the guide rails with horizontal or vertical grooves, for example, the motor is slidably connected to the base with the horizontal chute through bolts, and the base with the horizontal chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com