Method for bonding seamless joints of rubber conveying belt

A technology of seamless joints and conveyor belts, used in conveyors, transportation and packaging, etc., can solve the problems of inability to carry out material transportation, damage to the tape, easy to warp or be scraped, etc., to achieve significant economical and practicality, The effect of high bond strength, low cost connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

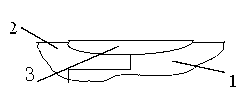

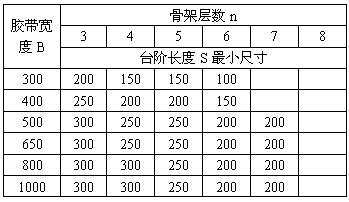

[0020] A rubber conveyor belt seamless joint method, the steps of the joint process include: (1) determining the lap length of the joint; (2) measuring the marking line; (3) cutting; (4) making the joint; (5) grinding , Cleaning, cleaning, drying; (6) Glue brushing; (7) Drying; (8) Bonding and hammering; (9) Grinding and strengthening sealing strips at the seamless joints of the two-stage rubber conveying belts 1 and 2 Groove; (10) Groove brushing glue; (11) Sealing reinforcement sealing strip put into sealing reinforcement sealing strip 3 groove hammering; (12) Health preservation and commissioning process.

[0021] The preparatory work is divided into two parts: tools and materials. Tools include tape measure (2m) and steel ruler for marking

[0022] 1.5 meters in size, paper cutter, leather pliers, rubber scraper, joint tray, rubber hammer, hair dryer or iodine tungsten lamp, hand grinding wheel and black sand disc, etc.; materials include specially selected belt adhesives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com