Wide-temperature MnZn power ferrite material

A ferrite material and power technology, applied in the field of MnZn power ferrite material production, can solve the problem of low Bs, and achieve the effect of high Bs and low loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

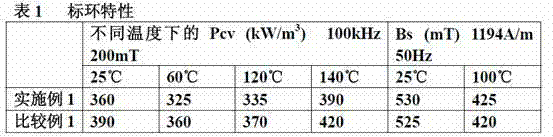

Embodiment 1

[0022] Weigh the main component raw materials according to the following main component content: Fe 2 o 3 Content is 52.7mol%, ZnO content is 9.7mol%, MnO content is 37.6mol%, dry and pass through 45 mesh / inch sieves after primary sand grinding; Carry out pre-calcination to the powder after primary sand grinding, pre-calcination temperature is 860°C, the time is 2 hours; add the auxiliary component raw materials weighed in proportion to the calcined material (the auxiliary component content based on the total weight of the main component is: CaCO 3 :0.04wt%, ZrO 2 :0.02wt%, Nb 2 o 5 :0.04wt%, SnO 2 : 0.1wt% and Co 2 o 3 : 0.35wt%), the ratio of material ball water is 1:6:2 when carrying out secondary sand grinding and sand grinding, the sand grinding time is 200 minutes, and the particle size obtained by sand grinding is 1.15 μ m; the above-mentioned secondary sand grinding material is dried And granulate, and then pressed under the pressure of 5MPa to a density of 3.0g...

Embodiment 2

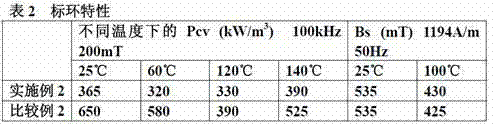

[0029] Weigh the main component raw materials according to the following main component content: Fe 2 o 3 content of 52.8mol%, ZnO content of 9.2mol%, MnO content of 38mol%, after the first sanding, drying and passing through a 45 mesh / inch sieve; pre-burning the powder after the first sanding, the pre-burning temperature is 860 ℃, the time is 2 hours; Add the auxiliary component raw materials weighed in proportion to the calcined material (the auxiliary component content based on the total weight of the main component is: CaCO 3 :0.04wt%, ZrO 2 :0.03wt%, Nb 2 o 5 :0.04wt%, SnO 2 : 0.1wt% and Co2 o 3 : 0.35wt%), the ratio of material ball to water is 1:6:2 when performing secondary sanding and sanding, the sanding time is 200 minutes, and the particle size obtained by sanding is 1.15 μm; the above-mentioned secondary sanding material is dried and Granulate, then press under 5MPa pressure to a density of 3.0g / cm 3 the standard ring.

Embodiment 3

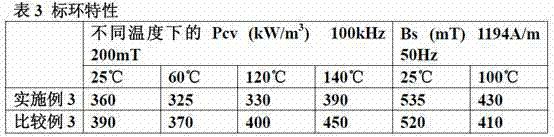

[0036] Weigh the main component raw materials according to the following main component content: Fe 2 o 3 content of 52.8mol%, ZnO content of 9.2mol%, MnO content of 38mol%, after the first sanding, drying and passing through a 45 mesh / inch sieve; pre-burning the powder after the first sanding, the pre-burning temperature is 860 ℃, the time is 2 hours; Add the auxiliary component raw materials weighed in proportion to the calcined material (the auxiliary component content based on the total weight of the main component is: CaCO 3 :0.04wt%, ZrO 2 :0.03wt%, Nb 2 o 5 :0.04wt%, SnO 2 : 0.15wt% and Co 2 o 3 : 0.35wt%), the ratio of material ball to water is 1:6:2 when performing secondary sanding and sanding, the sanding time is 200 minutes, and the particle size obtained by sanding is 1.15 μm; the above-mentioned secondary sanding material is dried and Granulate, then press under 5MPa pressure to a density of 3.0g / cm 3 the standard ring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com