A kind of preparation method of dicyclopentadiene petroleum resin modified rubber

A technology of dicyclopentadiene and petroleum resin, applied in the field of rubber materials, can solve the problem of increasing energy consumption in the mixing process, difficulty in controlling the uniformity of the dispersion of the dicyclopentadiene petroleum resin, and difficulty in fusing the raw rubber with the dicyclopentadiene petroleum resin. and other problems, to achieve the effects of good mechanical properties, low processing energy consumption, and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

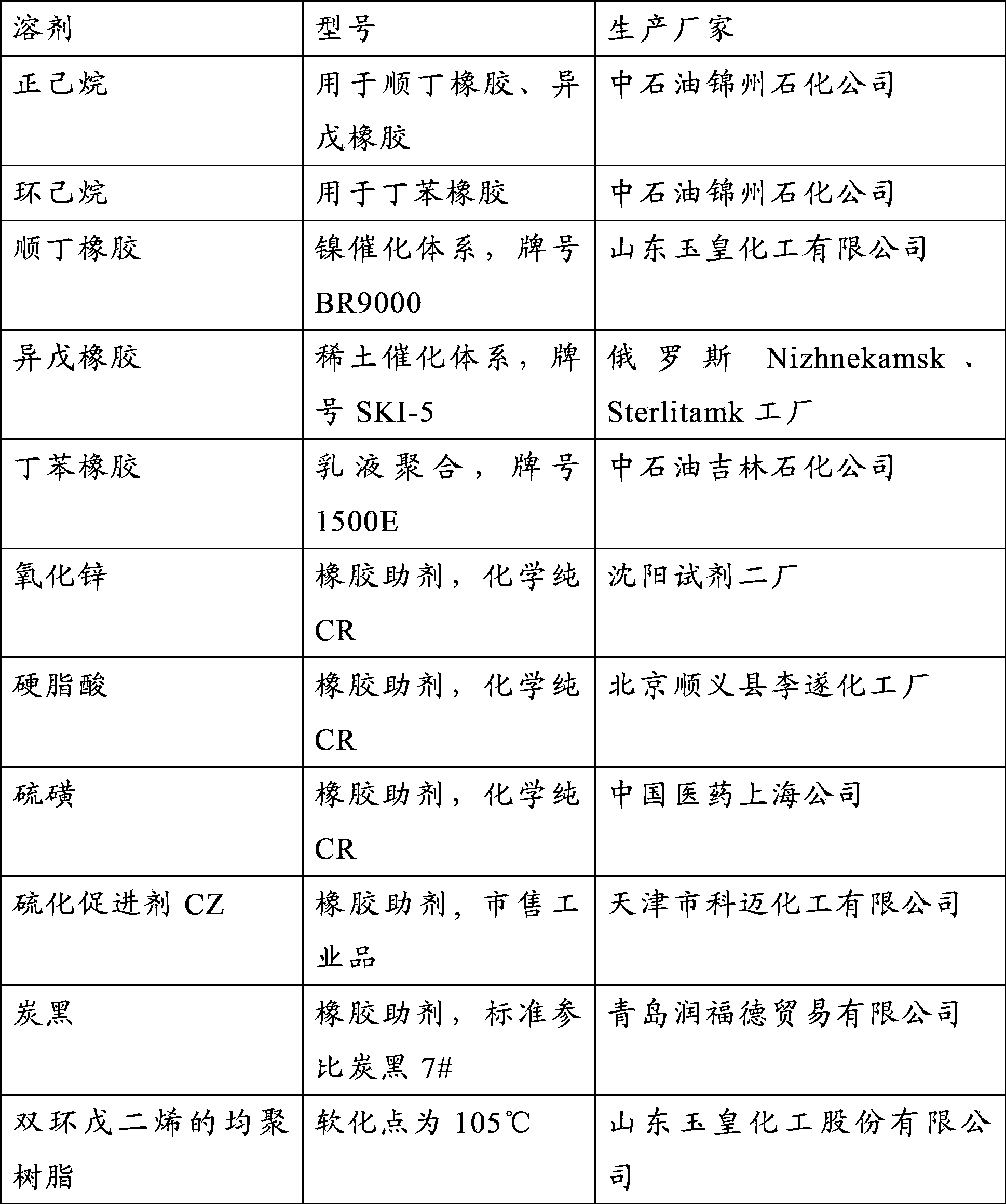

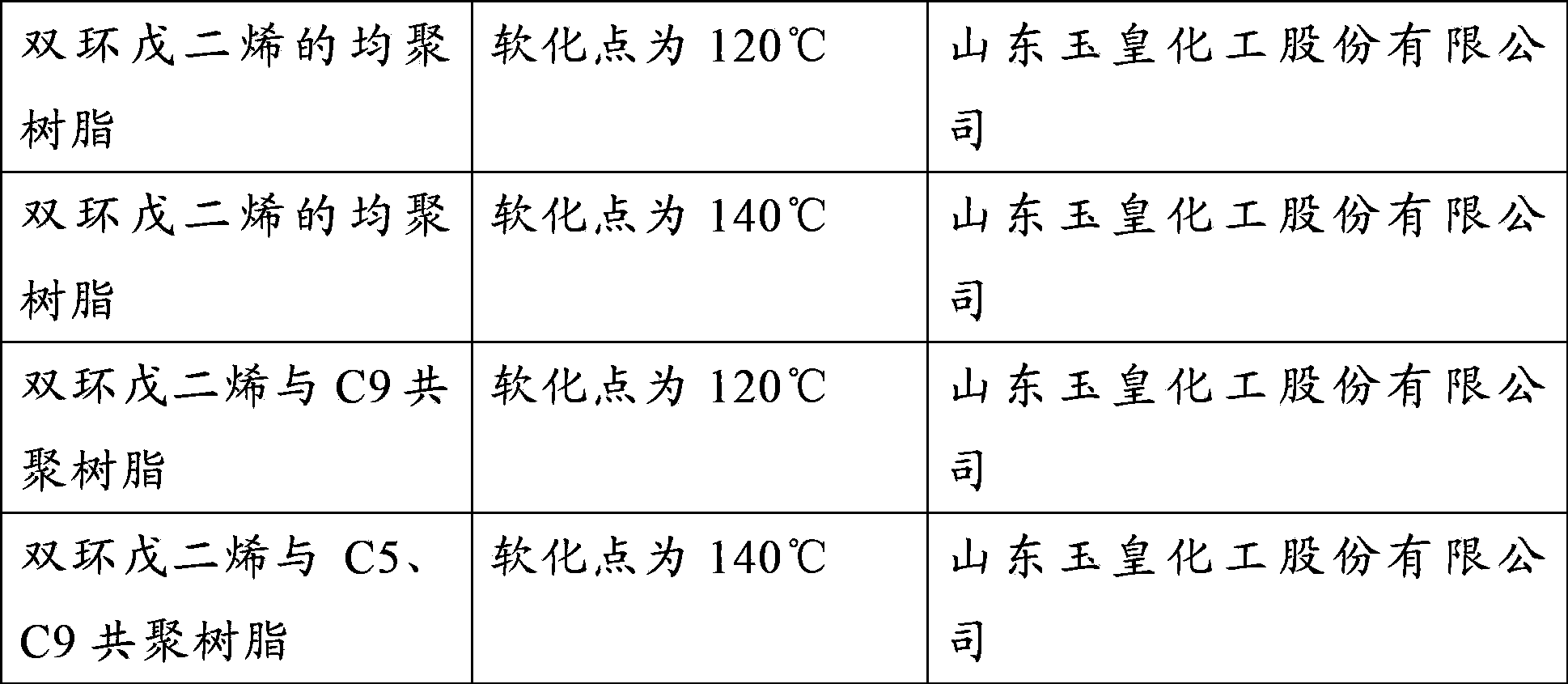

[0019] The embodiment of the present invention discloses a kind of preparation method of dicyclopentadiene petroleum resin modified rubber, comprising the following steps:

[0020] Mix rubber latex, dicyclopentadiene petroleum resin and compounding agents in an organic solvent, coagulate, extrude and dry to obtain modified raw rubber; the compounding agents are sulfur, dicumyl peroxide (DCP), N, N-tetramethyldithiobisthiocarbamide (TMTD), 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, azobisisobutyronitrile (AIBN) or Dibenzoyl Oxide (BPO);

[0021] The modified raw rubber is mixed with stearic acid, zinc oxide, sulfur, a vulcanization accelerator and carbon black, and the dicyclopentadiene petroleum resin modified rubber is obtained after tableting and vulcanization.

[0022] The invention uses rubber latex, dicyclopentadiene petroleum resin and compounding agent as raw materials, fully mixes the three in an organic solvent, and then dries to obtain modified raw rubber.

[00...

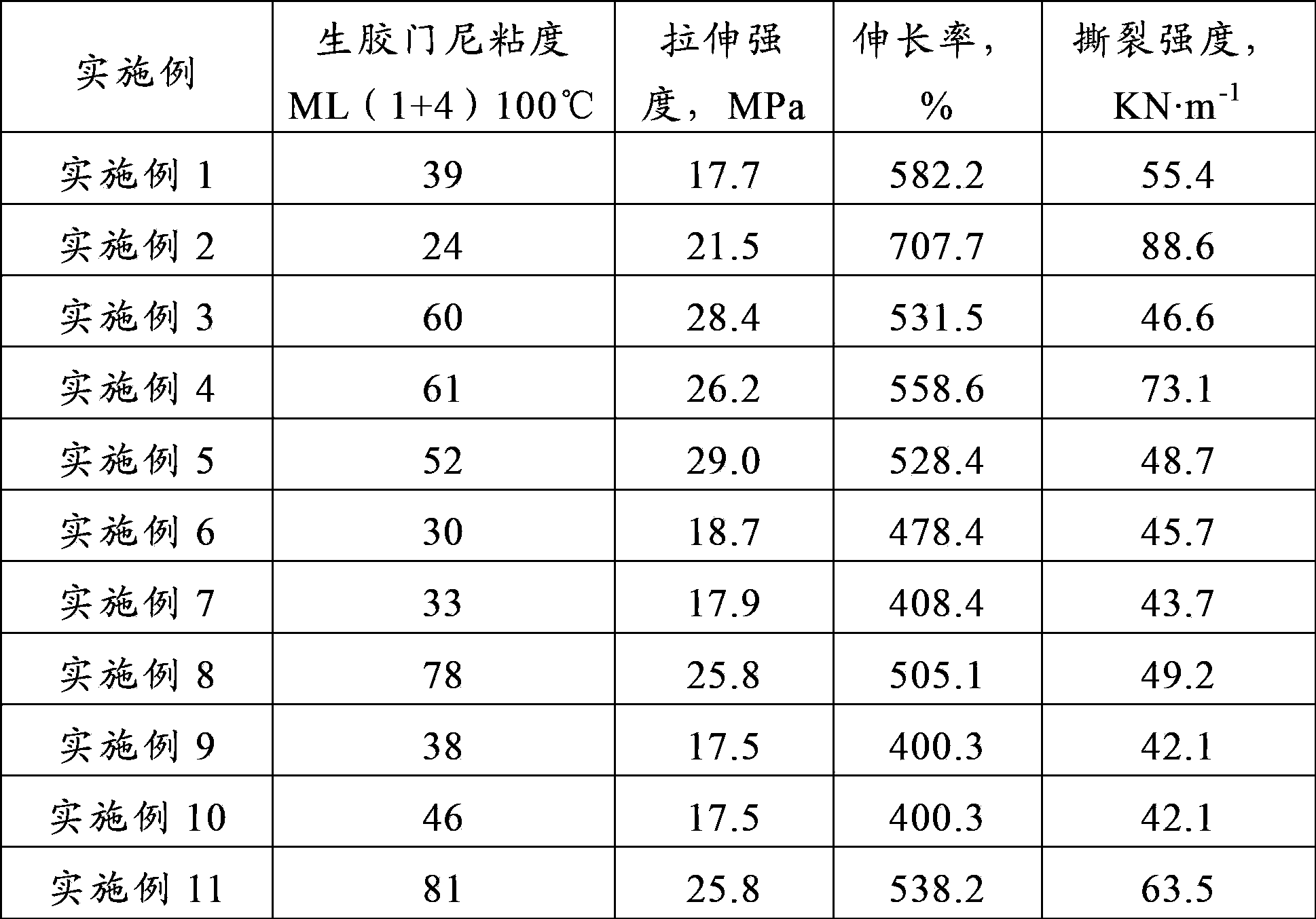

Embodiment 1

[0034] Mix 100 kg of butadiene rubber BR9000, 5 kg of dicyclopentadiene homopolymer resin with a softening point of 105°C and 1 kg of sulfur in n-hexane. After stirring evenly, the rubber liquid is condensed in water at 95°C. The volume ratio of glue to water is 1:10, and then extruded through a twin-screw extruder at an extrusion temperature of 90°C, a rotation speed of 60 rpm, and an extrusion time of 10 minutes to obtain modified raw rubber.

[0035] 200 grams of modified raw rubber, 4 grams of stearic acid, 6 grams of zinc oxide, 1.8 grams of N-cyclohexyl-2-benzothiazole sulfenamide (CZ), 3.0 grams of sulfur, 120 grams of carbon black, according to GB / T8660-2008 disclosed method for mixing. Put the kneaded rubber into a mold preheated to 145°C, keep constant pressure and temperature after repeated exhausting by a flat vulcanizer, and vulcanize for 30 minutes to obtain dicyclopentadiene petroleum resin modified rubber.

[0036] The mechanical properties of the obtained mo...

Embodiment 2

[0038] Mix 100 kg of butadiene rubber BR9000, 50 kg of dicyclopentadiene homopolymer resin with a softening point of 120°C and 8 kg of sulfur in n-hexane, and after stirring evenly, coagulate the rubber liquid in water at 100°C. The volume ratio of glue to water is 1:10, and then extruded through a twin-screw extruder at an extrusion temperature of 70°C, a rotation speed of 60 rpm, and an extrusion time of 10 minutes to obtain modified raw rubber.

[0039] 200 grams of modified raw rubber, 4 grams of stearic acid, 6 grams of zinc oxide, 1.8 grams of N-cyclohexyl-2-benzothiazole sulfenamide (CZ), 3.0 grams of sulfur, 120 grams of carbon black, according to GB / T8660-2008 disclosed method for mixing. Put the kneaded rubber into a mold preheated to 145°C, keep constant pressure and temperature after repeated exhausting by a flat vulcanizer, and vulcanize for 30 minutes to obtain dicyclopentadiene petroleum resin modified rubber.

[0040] The mechanical properties of the obtained m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com